2024 Aluminum Plate

2024 Aluminum Plate Related Searches

Aluminum Plate 2024 2024 Aluminum 2124 Aluminum Plate 24 X 24 Aluminum Plate 2024-T351 Aluminum Plate 2024 T851 Aluminum Plate 2024 T351 Aluminum Plate 2024 Aluminum Bar Stock 24 X 24 X 1/4 Aluminum Plate 2014 Aluminum Plate 20mm Aluminum Plate 12x24 Diamond Plate Aluminum 25 Aluminum Plate 1 4 Aluminum Plate 25mm Aluminum Plate 250 Aluminum Plate 4 Aluminum Plate 25 Inch Aluminum Plate 4x4 Aluminum Plate 40mm Aluminum Plate 3 4 Aluminum Plate 2017 Aluminum Plate 2124-T851 Aluminum Plate 1 2 Aluminum Plate 2219 Aluminum Plate Aluminum Floor Plate 4 X 4 Aluminum Plate Aluminum Wall Plate 12x12 Aluminum Plate White Aluminum Plate2024 Aluminum Plate Supplier & Manufacturer from China

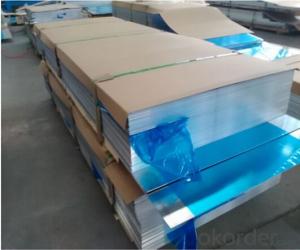

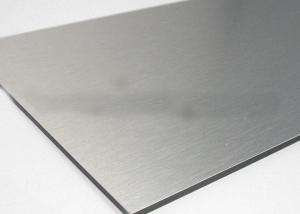

2024 Aluminum Plate, known for its excellent mechanical properties and high strength, is a popular choice among various industries. This alloy is widely recognized for its ability to withstand significant stress and is commonly used in applications such as aircraft structures, transportation equipment, and machinery components. The versatility of 2024 Aluminum Plate makes it suitable for a range of usage scenarios, from structural components to intricate parts requiring precision and durability. As a wholesale supplier, Okorder.com offers a vast inventory of 2024 Aluminum Plate, ensuring that customers have access to the quantity and quality they need for their projects. With a commitment to providing top-notch products, Okorder.com stands out as a reliable source for 2024 Aluminum Plate, catering to the demands of industries that require high-performance materials.Hot Products