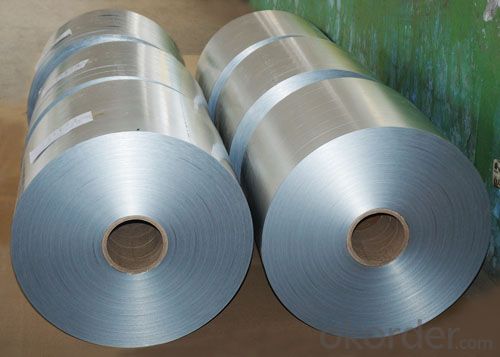

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils play a vital role in the production of sporting goods due to their lightweight, durable, and corrosion-resistant properties. These coils are primarily used in the manufacturing of sporting equipment such as baseball bats, tennis rackets, golf clubs, and bicycle frames. One of the key advantages of aluminum coils is their lightweight nature, which allows for enhanced maneuverability and improved performance. For instance, in the production of baseball bats, aluminum coils are used to create hollowed-out barrels that provide players with a better swing speed and increased power. Similarly, in tennis rackets and golf clubs, aluminum coils are utilized to construct the shaft, offering players greater control and maneuverability during gameplay. The durability of aluminum coils ensures that the sporting goods can withstand the rigors of intense physical activities. Whether it is the impact of a baseball hitting a bat or the force exerted on a bicycle frame during a rough ride, aluminum coils provide the necessary strength and resilience to withstand such pressures. This durability factor is crucial in ensuring the longevity of the sporting goods, reducing the need for frequent repairs or replacements. Furthermore, the corrosion-resistant properties of aluminum make it an ideal material for sporting equipment that may be exposed to various weather conditions or moisture. Aluminum coils are resistant to rust, ensuring that the sporting goods can maintain their performance and appearance over time. This quality is particularly beneficial in outdoor sports like golf or cycling, where exposure to rain, humidity, or perspiration is common. In summary, aluminum coils are extensively used in the production of sporting goods due to their lightweight, durable, and corrosion-resistant properties. These coils contribute to the overall performance, strength, and longevity of sporting equipment, enhancing the experience of athletes and enthusiasts alike.

- Q: What are environmentally friendly types of aluminum coil and do they exist?

- <p>Yes, there are environmentally friendly types of aluminum coil. These include recycled aluminum coils, which are made from aluminum that has been reprocessed and reused, reducing the need for new aluminum production and its associated environmental impact. Additionally, aluminum coils with a high recycled content are considered eco-friendly as they contribute to waste reduction and energy conservation. The production of recycled aluminum uses significantly less energy compared to virgin aluminum, making it a more sustainable choice.</p>

- Q: Can aluminum coils be used for architectural applications?

- Yes, aluminum coils can be used for architectural applications. Aluminum is a versatile and lightweight material that is commonly used in construction due to its durability, corrosion resistance, and ease of installation. It can be formed into coils and used for various architectural elements such as roofing, cladding, facades, gutters, and window frames.

- Q: May anyone tell me what's the product when hydrochloric acid reacts with aluminum?HCl + Al → ?

- you may separate the hydrogen by electrolysis. purely take your tube of gas and place the tube face down in salt water. Then get yet another attempt tube and fill it halfway with salt water. The salt interior the water helps the water to grow to be a greater powerful conductor it is by the fact NaCl is an ion. This ionizes the water and helps conduction. Then after installation the attempt tubes, get a batter and connect it to a dazzling and unfavourable plate with the corresponding terminals on the battery. Then turn on the battery. The water ought to separate out of the tube, leaving the hydrogen. the different tube with be crammed with all the water. to answer your 2d question.... The gas that would want again out to be hydrogen. 6HCl + 2Al = 2AlCl3 + 3H2(gas)

- Q: why is aluminum to the right side of the periodic table if it's a metal and why is it negatively charge if it's a mental. also if you combine it with like another metal will it be an ion since its positively charge or no because they are both metals

- It okorder /

- Q: How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils are widely used in the manufacturing of appliances due to their unique properties and versatility. They are primarily used in the production of heat exchangers, which are essential components in appliances such as refrigerators, air conditioners, and heaters. One of the main advantages of aluminum coils is their excellent thermal conductivity. This means that they can efficiently transfer heat from one area to another, making them ideal for applications where heat exchange is required. In appliances, aluminum coils help in cooling or heating processes by transferring heat between the refrigerant or coolant and the surrounding air or water. Furthermore, aluminum coils offer superior corrosion resistance compared to other metals, making them highly suitable for appliances that come into contact with moisture or other corrosive substances. This property ensures the durability and longevity of the appliances, as the coils are less likely to rust or corrode over time. Moreover, aluminum coils are lightweight, which contributes to the overall efficiency of appliances. The lightweight nature of aluminum reduces the energy required for transportation and installation, making it a more sustainable choice. Additionally, the lightweight coils allow for more compact designs, maximizing space utilization in appliances. Another advantage of aluminum coils is their malleability. They can be easily shaped and formed into different sizes and configurations, allowing for customized designs that suit specific appliance requirements. This flexibility in design enables manufacturers to create efficient heat exchangers that fit into the limited space available in appliances. In summary, aluminum coils are used in the manufacturing of appliances due to their excellent thermal conductivity, corrosion resistance, lightweight nature, and malleability. These properties make them an ideal choice for heat exchangers, which are crucial components in appliances that require efficient cooling or heating processes.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: This question asks about the environmental effects associated with the use of aluminum coils.

- <p>The environmental impacts of using aluminum coils include energy consumption during production, potential release of greenhouse gases, and waste generation. Aluminum production requires significant energy, contributing to carbon emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. However, aluminum is highly recyclable, and recycling it saves energy and reduces waste. Proper disposal and recycling practices can mitigate some of these impacts, making aluminum a more sustainable choice when managed correctly.</p>

- Q: I have a 1994 Impala SS with a 5.7L lt1 engine with cast iron heads. Which is better in horsepower gain? Aluminum heads or cast iron heads? People say cast iron heads downsize the hp from 300 to 260 hp. Also which of the two heads are more durable and less restrictive?

- only difference is weight and aluminum is easier to repair

- Q: Can aluminum coils be used in electrical applications?

- Yes, aluminum coils can be used in electrical applications.

Send your message to us

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords