Home Depot Aluminum Coil 1060 Aluminum Alloy H14 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

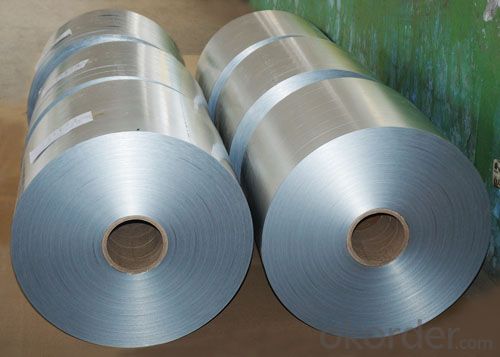

Aluminum Coil 1060 Aluminum Alloy H14 Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: I am wondering if a deodorant made with aluminum silicate is safer than one with aluminum salt.

- aluminum silicates have been used in deodorants for years. there was a time when it was thought that the Al in the deodorants was causing alzheimers but that has been shown to be wrong. if there are other dangers to the silicates, we haven't found them or they aren't that bad

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

- Q: ok me and my father are trying to make thermite. we have the iron oxide but the aluminum we only have paste and i was wondering would it work the same as if we had the powder.and if it is differnt will it work for the thermite and what will it take to light it.

- You okorder /

- Q: Can aluminum coils be utilized as materials for constructing roofs?

- <p>Yes, aluminum coils can be used for roofing materials. They are known for their durability, corrosion resistance, and lightweight properties, making them an excellent choice for roofing. Aluminum's reflective surface also helps in energy efficiency by reflecting sunlight and reducing heat absorption. It's recyclable and has a long lifespan, which contributes to its sustainability. However, it's important to ensure that the aluminum coils are of the appropriate gauge and quality for the specific roofing application to guarantee structural integrity and performance.</p>

- Q: Can aluminum coils be used in the production of aluminum honeycomb panels?

- Aluminum honeycomb panels can indeed incorporate aluminum coils in their production process. To create these panels, aluminum sheets are affixed to a honeycomb core material, typically composed of aluminum as well. The aluminum coils are commonly employed to manufacture the aluminum sheets forming the panels' outer layer. After being rolled into thin sheets, these coils are cut to the desired dimensions and subsequently bonded to the honeycomb core. The utilization of aluminum coils enables the efficient and cost-effective manufacture of aluminum honeycomb panels, as they can be easily molded and processed to meet the necessary shape and size requirements. Moreover, aluminum possesses the qualities of being lightweight and durable, rendering it an optimal selection for fabricating honeycomb panels utilized in diverse industries, including aerospace, construction, and transportation.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- In the electrical industry, aluminum coils are commonly used for various applications such as transformers, motors, and electrical enclosures. These coils are often subjected to different surface finishing processes to enhance their performance and longevity. One of the most common surface finishes for aluminum coils in the electrical industry is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This layer not only provides excellent corrosion resistance but also improves the coil's durability and electrical insulation properties. Another popular surface finish is chemical conversion coating, also known as chromate conversion coating. This process involves treating the aluminum surface with a chemical solution to create a thin layer of protective coating. The coating not only provides corrosion resistance but also improves the adhesion of subsequent coatings or paints applied to the coil. Powder coating is another common surface finish used in the electrical industry for aluminum coils. It involves applying a dry powder onto the coil's surface and then curing it under heat to create a durable and attractive finish. Powder coating provides excellent resistance to chipping, scratching, and fading, making it ideal for applications where aesthetics and durability are important. In addition to these surface finishes, aluminum coils in the electrical industry may also undergo other treatments such as lacquering or painting. Lacquering involves applying a clear protective coating to the coil's surface, providing a glossy and protective finish. Painting, on the other hand, involves applying a colored coating to the surface for aesthetic purposes while also providing protection against corrosion. Overall, the choice of surface finish for aluminum coils in the electrical industry depends on the specific requirements of the application. Factors such as corrosion resistance, electrical insulation, durability, and aesthetics play a significant role in determining the most suitable surface finish for a given application.

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum is a preferred material for the manufacturing of beverage cans due to its lightweight, durability, and ability to preserve the taste and quality of the contents. Coils made of aluminum are typically used in the canning process as they can be easily shaped into a can form. The coils are rolled into sheets, which are then cut and formed into cans. Aluminum coils also have excellent heat conductivity, allowing for efficient cooling and faster production speeds. Overall, aluminum coils are an essential component in the production of beverage cans and are widely used in the industry.

- Q: What are the different coil lengths available for aluminum coils?

- There are several different coil lengths available for aluminum coils, depending on the specific application and requirements. Generally, aluminum coils can be found in lengths ranging from a few feet to several hundred feet. The most common coil lengths for aluminum coils used in various industries, such as HVAC, automotive, and construction, are typically 50 feet, 100 feet, and 250 feet. However, it's important to note that custom coil lengths can also be manufactured based on the specific needs of the customer. These custom lengths can vary depending on factors like coil thickness, width, and intended use. Ultimately, the available coil lengths for aluminum coils are flexible and can be tailored to suit the needs of different industries and applications.

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- I think the 0.14mm is certainly not the aluminum coil lining sleeve forgot, then the biggest doubt is the oil removal effect is not good, with rolling after the aluminum layer between the leakage for aluminium roll support is not enough, the collapse of the volume, the specific performance is the edge of the circular aluminum layer was uniform into ripples; in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

Send your message to us

Home Depot Aluminum Coil 1060 Aluminum Alloy H14 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords