The Wear-Resistant Pressure Epoxy Floor Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

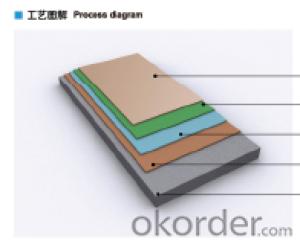

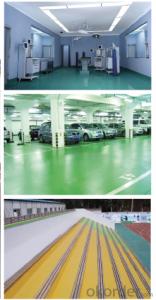

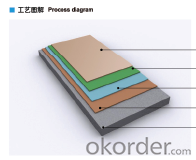

The wear-resistant weight epoxy floor coating developed adopting international advanced materials and technologies is suitable for the grounds, with high mechanical performance, and a certain impact, such as: underground garages, heavy trucks, forklifts, frequent moving rolling wheels of forklifts, accumulation of heavy cargo and large machine workshops with dustproof requirement for sophisticated technology processing and production, weight workshops of machinery and equipment, auto repair shops, electronics industry, storerooms and other places with heavy loads.

2.Main Features

* The overall ground is seamless, and is easily cleaned and will not keep hidden dust and bacteria;

* Surface wear-resistance, durable;

* Acid, alkali, salt and other corrosive chemicals resistance;

* Resistance to gasoline, oil and diesel oil erosion, not leak, easy to clean;

* The ground coating is non-toxic, and meets the health requirements;

* Rich surface colors can beautify the working environment.

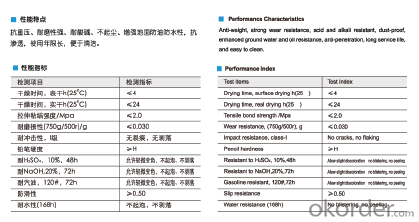

3.Technical Parameters

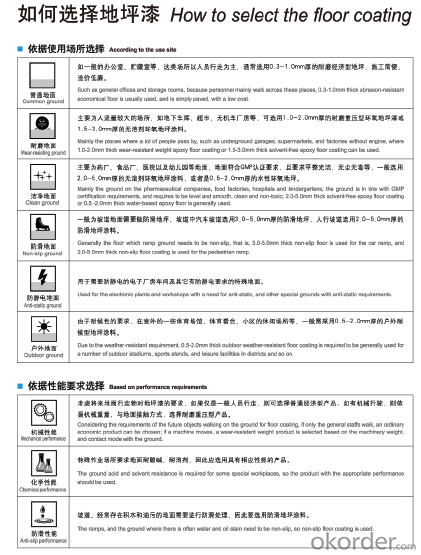

4.How to selected the floor Coating

5.Applications

What base materials is the epoxy floor coating suitable for?

Decoration of new concrete ground, and renovation of old concrete, ceramic tile, marble, terrazzo and other ground surfaces

- Q: What are the dyes that do stained paper cutting?

- Dyes are substances that make fibers and other materials colored, divided into natural and synthetic categories. Dyes are colored. But the color of the material is not necessarily a dye. Dye is able to make a certain color attached to the fiber on the material, and easy to fall off, discoloration. Dyes are usually dissolved in water, and some dyes require mordant to allow the dye to adhere to the fibers. Archaeological data show that dyeing technology in India and the Middle East has more than five thousand years of history. At that time the dyes from the flora and fauna or minerals, rarely treated.

- Q: My walls are painted a light color and there are many dirty marks on them. Is there a way to clean them without harming the paint?

- I agree with FaZizzle but you might try adding vinegar to the soapy water to cut through any crud.

- Q: A KG latex paint can generally brush the number of areas of the wall, the ground, the top.

- Theoretical coverage of about 10 square meters / liter (again), and the absorption of the substrate.

- Q: shine like car paint but how?

- I use oil based high gloss paints. First of all I sand the surface using three different sand papers, starting with the most coarse and working my way to the finest. I wipe it clean with methylated spirits because it dries instantly and there is no water to make the timber swell or affect the paint in any way. I apply a good quality undercoat, usually oil based. If you can find a ridge filler undercoat, it will help even out flaws. If you have large pits or dents you might want to fill with an appropriate filler. Leave for a minimum of 12 hours and sand with a fine grade paper. Wipe off with metho again. Feel with your fingers - if you can feel bumps you will be able to see them, so you may need to sand a little more. For the paint: use the best quality brush you can afford. Ask for advice in the paint store if you are unsure. Load your brush with a small amount of paint. If it's a small item you should be able to do a stroke the full length in one go. If not, you will need to reload mid stroke. Apply the paint, reload and pick up where you left off. When one length is complete, go back and lay off in the opposite direction, that is to brush the paint all in the same direction. Work quickly. When you have completed your first coat, leave to dry for a minimum of 12 hours and repeat the sand and paint process again. I usually do three coats of oil based paint, but you may not need to. If I'm doing a clear finish on a timber project, I will rub boiled linseed oil into the clear finish with a very, very fine steel wool. It gives a lovely soft finish. There are also two pack products available which can be sprayed on and give a very high gloss finish, but I have never used those.

- Q: Latex paint wall and acrylic paint wall difference, seeking master Xiangjie!

- Pure acrylic acid emulsions are all synthesized using acrylic monomers, and acrylic copolymers are synthesized together with acrylic monomers using some styrene monomer or vinyl acetate monomer in place of acrylic monomers, in addition to the use of acrylic monomers. Do on the one hand can reduce costs, on the one hand the film performance can also be some modification. Usually pure acrylic emulsion has better resistance to sun drying, so whether it is indoor or outdoor use latex paint can be used, and acrylic acid copolymer due to the use of styrene monomer or vinyl acetate monomer and other monomers, in the Sun-resistant performance may be less than pure acrylic emulsion, so used in indoor use more.

- Q: Paint construction should pay attention to what?

- Note that the construction temperature, indoor and outdoor temperature difference can not be ignored

- Q: Will the temperature difference affect the density of the paint

- influences. The temperature is so fast.

- Q: How to quickly remove the paint on the clothes

- If it is oily, you can use alcohol bubble, and then washed just fine

- Q: So I'm planning on painting my nightstand and this other table white because they're both an ugly brown colour. I was wondering is it better to use spray paint or regular paint from the can to paint them? They're both wooden if it helps. Thanks c:

- I'd say spray paint. It's much more toxic but the finished result is very smooth and even. A regular brush (even soft bristled ones) creates streaks in the paint.

- Q: I am the Epson R230 is now the dye with the supply, I heard that modified paint to play pictures for a long time, will not fade, I would like to ask how the modified paint, If the modified paint, is not only print photos? The color will not be better than the fuel effect, want to know the friend can tell you no time to add you next time

- Dye ink and pigment ink the advantages and disadvantages of comparison: dye ink colorful, ink fluency, and cheap. The biggest drawback is easy to be outside the light, air humidity and other factors, especially the strong light is easy to fade photos, save time is not long. Pigment ink is not easy to fade, you can save for decades, little change in color. But the color of the printed picture is not satisfactory, always gives a contrast is not enough, there is a slightly dark feeling. And the ink price is very expensive, ink fluency is poor, easy to plug. Replace the pigment ink, the best replacement with the supply, do not use the original even for the supply. Because once the deal is not good, the risk of nozzle clogging is larger.

Send your message to us

The Wear-Resistant Pressure Epoxy Floor Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords