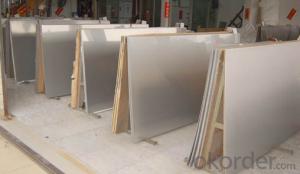

Stainless Steel 304 sheet for wholesale only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: What is the difference between 904L and 316 stainless steel pipes?

- 904L and 316 stainless steel are commonly utilized materials in various industries for pipe manufacturing. The distinction between these two grades lies in their composition, properties, and applications. 1. Composition: - In terms of composition, 904L stainless steel contains elevated levels of chromium, nickel, and molybdenum, along with copper. It possesses a higher alloy content compared to 316 stainless steel. - On the other hand, 316 stainless steel, also referred to as marine grade stainless steel, contains significant amounts of chromium, nickel, and molybdenum. However, it does not include copper in its composition. 2. Corrosion Resistance: - In terms of corrosion resistance, 904L stainless steel exhibits remarkable resistance, particularly in aggressive environments like seawater and acidic conditions. Its high content of chromium, nickel, and molybdenum ensures superior protection against pitting and crevice corrosion. - Similarly, 316 stainless steel offers excellent corrosion resistance, especially in marine and chloride-rich environments. However, it is not as resistant to corrosion as 904L stainless steel. 3. Strength and Durability: - When considering strength and durability, 904L stainless steel demonstrates higher levels compared to 316 stainless steel due to its increased content of nickel and molybdenum. It can endure higher pressures and temperatures, making it suitable for applications in extreme conditions. - On the other hand, while 316 stainless steel possesses good strength and durability, it falls slightly behind 904L stainless steel in this regard. 4. Applications: - 904L stainless steel pipes find common usage in industries such as petrochemical, chemical processing, oil and gas, and marine applications. They prove ideal for environments with high chloride levels and acidic conditions. - Conversely, 316 stainless steel pipes are widely employed across various industries, including food processing, pharmaceuticals, architecture, and marine applications. They are suitable for general-purpose applications where corrosion resistance is required, but not as crucial as in aggressive environments. In summary, although both 904L and 316 stainless steel pipes provide corrosion resistance, 904L stainless steel showcases superior performance in aggressive environments owing to its higher alloy content. However, 316 stainless steel finds greater prevalence in general-purpose applications where an extremely high level of corrosion resistance is not essential.

- Q: What is the difference between 304L and 316L stainless steel pipes?

- 304L and 316L are both types of stainless steel pipes, but they differ in terms of their chemical composition and specific properties. 304L stainless steel is a low carbon variation of 304 stainless steel, which means it has a lower carbon content. This makes it more resistant to sensitization, which is the formation of chromium carbide at grain boundaries, leading to intergranular corrosion. Due to its lower carbon content, 304L stainless steel pipes are commonly used in environments where sensitization is a concern, such as in welding applications or in corrosive environments. On the other hand, 316L stainless steel is an austenitic stainless steel that contains molybdenum, which gives it improved corrosion resistance compared to 304L stainless steel. The addition of molybdenum enhances its resistance to pitting and crevice corrosion, making it suitable for use in more aggressive environments such as marine environments or chemical processing plants. In terms of mechanical properties, 316L stainless steel pipes generally have higher tensile strength and yield strength compared to 304L stainless steel pipes. This makes 316L stainless steel pipes more suitable for applications requiring higher strength and durability. In summary, the main difference between 304L and 316L stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304L stainless steel pipes are more resistant to sensitization, while 316L stainless steel pipes offer higher corrosion resistance, particularly in more aggressive environments. The choice between the two types depends on the specific application requirements and the environment in which the pipes will be used.

- Q: Are stainless steel pipes suitable for pharmaceutical laboratories?

- Yes, stainless steel pipes are suitable for pharmaceutical laboratories. Stainless steel is highly resistant to corrosion, easy to clean, and it does not react with most chemicals. It also has high temperature and pressure resistance, making it a reliable choice for transporting various pharmaceutical substances. Additionally, stainless steel pipes are durable, hygienic, and meet the strict standards and regulations of pharmaceutical industries.

- Q: Are stainless steel pipes suitable for pharmaceutical industries?

- Yes, stainless steel pipes are highly suitable for pharmaceutical industries. They offer excellent corrosion resistance, durability, and hygienic properties, making them ideal for transporting and storing pharmaceutical products. Stainless steel pipes are easy to clean, maintain, and sterilize, ensuring the integrity and safety of the pharmaceutical products being handled. Additionally, stainless steel is non-reactive, meaning it does not contaminate or affect the quality of the pharmaceutical substances being transported, making it a reliable choice for the pharmaceutical industry.

- Q: How do you prevent galling in stainless steel pipes?

- Stainless steel pipes often encounter a frustrating problem called galling, or cold welding. If not dealt with properly, this issue can cause damage and even failure. Fortunately, there are several steps that can be taken to prevent galling in stainless steel pipes: 1. Lubrication is key. By applying a suitable lubricant to the threaded connections, the risk of galling can be significantly reduced. Lubricants create a barrier between the mating surfaces, minimizing friction and preventing the metal-to-metal contact that leads to galling. It's important to use a lubricant specifically designed for stainless steel to ensure compatibility and effectiveness. 2. Proper pipe installation is crucial. Over-tightening the connections can increase the risk of galling, so it's important to avoid this. Following the torque specifications recommended by the manufacturer and using a calibrated torque wrench can ensure proper installation without putting excessive stress on the threads. 3. Avoiding the use of dissimilar metals in the joint is important when connecting stainless steel pipes. If dissimilar metals come into contact, galvanic corrosion can occur, leading to galling. However, if it's necessary to use dissimilar metals, isolating gaskets or other insulating materials can be employed to prevent direct contact between the metals. 4. Maintaining a smooth surface finish on the threads can help minimize the risk of galling. Rough or damaged threads can create areas of high friction, increasing the likelihood of galling. Thoroughly inspecting and cleaning the threads before installation can help identify any imperfections that need to be addressed. 5. Material selection is crucial in preventing galling. Choosing the right grade of stainless steel is essential. Certain stainless steel alloys, such as 304 and 316, are more resistant to galling due to their higher nickel content. Consulting with a materials expert or referring to industry standards can help determine the most suitable stainless steel grade for a specific application. By implementing these preventive measures, the risk of galling in stainless steel pipes can be significantly reduced, ensuring the longevity and reliability of the piping system.

- Q: How do stainless steel pipes compare to fiberglass pipes?

- Stainless steel pipes and fiberglass pipes have distinct characteristics and advantages that set them apart. When comparing stainless steel pipes to fiberglass pipes, several factors should be considered, including strength, durability, corrosion resistance, cost, and ease of installation. In terms of strength, stainless steel pipes have a clear advantage. They are known for their exceptional strength and durability, making them ideal for withstanding high-pressure applications and heavy loads. On the other hand, fiberglass pipes are relatively weaker and may not be suitable for applications that require high strength and resistance. Durability is another crucial aspect to consider. Stainless steel pipes are highly durable and can withstand extreme temperatures, chemicals, and physical stress without deteriorating. Fiberglass pipes, although durable, are more susceptible to damage from impact, extreme temperatures, and UV radiation. This makes stainless steel pipes a more reliable choice for long-term use in harsh environments. Corrosion resistance is a significant factor in pipe selection. Stainless steel pipes are renowned for their excellent corrosion resistance, making them ideal for applications where exposure to corrosive substances is a concern. Fiberglass pipes, while relatively resistant to many chemicals, can be affected by certain corrosive substances and may require additional protective coatings. Cost is an important consideration for any project. Stainless steel pipes tend to be more expensive than fiberglass pipes due to the higher cost of raw materials and manufacturing processes. Fiberglass pipes, on the other hand, are generally more affordable, making them a cost-effective option for projects with budget constraints. Finally, ease of installation is worth mentioning. Stainless steel pipes require specialized tools and expertise for installation due to their weight and rigidity. Fiberglass pipes, being lightweight and flexible, are easier to handle and install, reducing labor costs and time. In conclusion, stainless steel pipes offer superior strength, durability, and corrosion resistance compared to fiberglass pipes. However, fiberglass pipes are a more cost-effective option and easier to install. The choice between the two ultimately depends on the specific requirements of the project, considering factors such as the application, budget, and environmental conditions.

- Q: Can stainless steel pipes handle high-velocity fluid flow?

- High-velocity fluid flow can indeed be handled by stainless steel pipes. Renowned for their remarkable strength, durability, and corrosion resistance, stainless steel pipes are well-suited for managing high-velocity fluid flow. They possess the ability to endure the pressure and turbulence created by swiftly moving fluids. Moreover, the smooth inner surfaces of stainless steel pipes reduce friction and aid in sustaining the velocity of the fluid flow. As a consequence, stainless steel pipes find widespread application in industries like oil and gas, chemical processing, and power generation, where encounters with high-velocity fluid flow are frequent.

- Q: Can stainless steel pipes be used for power plants?

- Indeed, power plants can utilize stainless steel pipes. The selection of stainless steel for power plant purposes is frequently made as a result of its exceptional resistance to corrosion and its ability to endure elevated temperatures and pressures. Given that power plants commonly operate in aggressive surroundings, they necessitate materials that can endure these conditions without deterioration. With its outstanding resistance to corrosion from chemicals, gases, and water, stainless steel pipes are perfectly suited for power plant applications. Furthermore, these pipes necessitate minimal maintenance, thereby reducing downtime and overall expenses.

- Q: What is the difference between seamless and cold-drawn stainless steel pipes?

- Seamless and cold-drawn stainless steel pipes differ in terms of their manufacturing methods and characteristics. Seamless stainless steel pipes are produced without any welding or seams. The process involves piercing a solid cylindrical billet or ingot of stainless steel and rolling it into a hollow tube shape. This seamless manufacturing technique guarantees the absence of weak points or areas prone to leakage, resulting in highly durable and reliable pipes. Additionally, the interior surface of seamless pipes is smoother, facilitating efficient fluid flow and reducing the risk of corrosion. In contrast, cold-drawn stainless steel pipes are manufactured by pulling or drawing a solid stainless steel billet through a series of dies at room temperature. This method ensures precise dimensions and a smooth surface finish. Cold-drawn pipes are commonly used in applications that require tight tolerances and a high-quality surface appearance. They are renowned for their exceptional dimensional accuracy, excellent surface finish, and increased strength. In terms of properties, seamless stainless steel pipes exhibit superior resistance to corrosion, higher strength, and increased pressure rating compared to cold-drawn pipes. The absence of welds also makes seamless pipes less susceptible to cracking or failure under high-pressure conditions. On the other hand, cold-drawn stainless steel pipes are valued for their outstanding surface finish, close dimensional tolerances, and enhanced mechanical properties. Consequently, they are suitable for applications that demand precise measurements and a smooth aesthetic. In summary, the primary distinction between seamless and cold-drawn stainless steel pipes lies in their manufacturing methods, resulting properties, and applications. Seamless pipes, manufactured without welding or seams, offer superior resistance to corrosion, increased strength, and higher pressure rating. Conversely, cold-drawn pipes, produced by pulling solid stainless steel through dies, provide excellent surface finish, dimensional accuracy, and improved mechanical properties.

- Q: What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or surface finish on the inner walls of the pipe. It is a measure of the irregularities or bumps present on the internal surface. The roughness is usually quantified by measuring the average height of these irregularities, typically expressed as Ra (arithmetical mean deviation of the profile) or Rz (maximum height of the profile). Stainless steel pipes are known for their smooth and corrosion-resistant properties, which make them suitable for various applications in industries such as oil and gas, food processing, pharmaceuticals, and chemicals. The internal roughness of stainless steel pipes is typically low, resulting in minimal frictional resistance to fluid flow and improved hygienic properties. The internal roughness can vary depending on the manufacturing process, the grade of stainless steel, and the intended application. Stainless steel pipes can be manufactured with different surface finishes, such as pickled, annealed, or polished, which can affect the internal roughness. Polished surfaces generally have lower roughness values, providing smoother flow and minimizing the risk of contamination in applications that require high cleanliness standards. It is important to consider the internal roughness of stainless steel pipes when designing systems that involve fluid flow, as it can impact the pressure drop, flow rate, and overall efficiency. The roughness value is often taken into account in fluid dynamics calculations, such as determining the friction factor in pipe flow equations. To ensure the desired internal roughness, stainless steel pipes are often subjected to post-processing treatments, such as electropolishing or mechanical polishing, which can further reduce the roughness and improve the surface finish. These treatments enhance the performance and longevity of stainless steel pipes in critical applications where minimal frictional resistance, high cleanliness, and corrosion resistance are essential.

Send your message to us

Stainless Steel 304 sheet for wholesale only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords