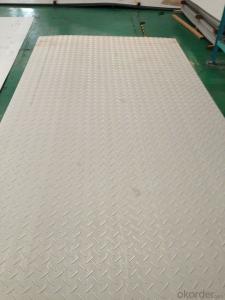

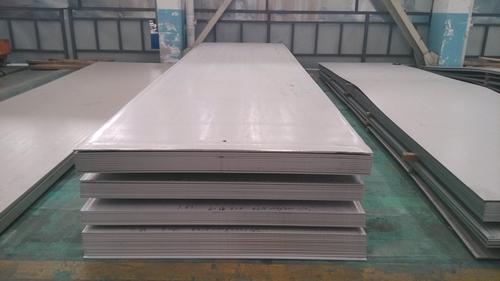

Stainless Steel 304 sheet for exporting only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: How do stainless steel pipes compare to PVC pipes?

- Stainless steel pipes and PVC pipes are both widely used in various industries and applications, but they have distinct differences that make them suitable for different purposes. One of the key differences is the material composition. Stainless steel pipes are made from an alloy of iron, chromium, and other elements, which provides excellent strength and corrosion resistance. On the other hand, PVC pipes are made from a synthetic plastic polymer known as polyvinyl chloride, which offers good chemical resistance but is not as strong as stainless steel. In terms of strength and durability, stainless steel pipes have the upper hand. They can withstand high pressure and are highly resistant to heat, making them ideal for applications that involve transporting hot liquids or gases. PVC pipes, although not as strong, are lightweight and flexible, which makes them easier to handle and install in certain applications. Another important aspect to consider is the cost. PVC pipes are generally more affordable than stainless steel pipes, making them a popular choice for residential plumbing and other low-pressure applications. Stainless steel pipes, being more expensive, are often used in industrial settings where their superior strength and corrosion resistance are necessary. When it comes to lifespan, stainless steel pipes have a longer life expectancy compared to PVC pipes. Stainless steel is highly resistant to corrosion, rust, and other chemical reactions, which allows it to maintain its structural integrity over a longer period of time. PVC pipes, while durable, can degrade over time due to exposure to UV light, extreme temperatures, and certain chemicals. In terms of environmental impact, PVC pipes have raised concerns over the years due to the production and disposal of PVC, which involves the release of toxic chemicals. Stainless steel pipes, on the other hand, are considered more environmentally friendly as they can be recycled and have a longer lifespan. In summary, stainless steel pipes and PVC pipes have their own unique characteristics and advantages. Stainless steel pipes excel in strength, durability, and corrosion resistance, making them suitable for high-pressure and high-temperature applications. PVC pipes, on the other hand, are lightweight, affordable, and easy to install, making them a popular choice for low-pressure applications. Ultimately, the choice between these two materials depends on the specific requirements and constraints of the project at hand.

- Q: Why pickling before cleaning stainless steel pipe oil?

- Remove the welding slag, dust particles, impurities, oil and other pollutants produced in the installation, so as to avoid polluting the oil products.Avoid polluting oil products.

- Q: Can stainless steel pipes be used for offshore oil rigs?

- Certainly! Offshore oil rigs can indeed utilize stainless steel pipes. Due to its exceptional durability and resistance to corrosion, stainless steel emerges as a fitting material for offshore settings that confront challenging circumstances like saltwater and extreme temperatures. Its corrosion resistance guarantees the pipes' endurance and steadfastness, minimizing the likelihood of leaks or breakdowns in the oil rig's framework. Moreover, stainless steel pipes boast remarkable mechanical properties that enable them to endure high pressures and uphold structural integrity, rendering them a dependable option for offshore oil rigs.

- Q: What is the maximum temperature for stainless steel pipes?

- The maximum temperature for stainless steel pipes depends on the specific grade of stainless steel being used. Generally, austenitic stainless steels, such as grades 304 and 316, can withstand high temperatures up to 1600-1800°F (870-980°C). However, it is important to consider factors such as the duration of exposure, the presence of corrosive environments, and the specific application requirements. Other grades of stainless steel, such as ferritic or martensitic stainless steels, may have lower maximum temperature limits. It is advisable to consult the manufacturer's specifications and engineering guidelines to determine the appropriate maximum temperature for a particular stainless steel pipe.

- Q: Can stainless steel pipes be tempered?

- Stainless steel pipes have the capability to undergo tempering, which is a heat treatment technique commonly employed to enhance the mechanical properties of steel. To achieve this, the stainless steel pipes are heated to a specific temperature and then carefully cooled. This procedure aids in reducing the steel's hardness and brittleness, thus increasing its ductility and resistance to cracking or breaking. Moreover, tempering can also improve the corrosion resistance of stainless steel pipes. However, it is worth noting that the tempering process and temperature requirements can vary depending on the specific grade of stainless steel utilized. Therefore, it is vital to consult the manufacturer's guidelines or seek advice from a metallurgical expert in order to determine the appropriate tempering procedure for stainless steel pipes.

- Q: Can stainless steel pipes be pickled and passivated?

- Stainless steel pipes do have the capability to undergo pickling and passivation. Pickling refers to the elimination of impurities and scale from the surface of the stainless steel, whereas passivation involves applying a protective oxide layer on the surface to improve its resistance to corrosion. Various acidic solutions and techniques are employed in the pickling and passivation process, depending on the specific needs of the pipes and the desired results. This procedure is commonly employed in industries such as oil and gas, chemical, and food processing to ensure the purity and durability of stainless steel pipes.

- Q: The difference between galvanized steel pipe and stainless steel pipe

- Plastic pipe, plastic pipe, also known as plastic composite pipe, with steel pipes for the matrix, by spraying, rolling, leaching, absorption process in steel tube (bottom tube) steel plastic composite pipe internal surface is welded with a layer of plastic coating or plastic anti-corrosion layer on the inner surface and the outer surface of the weld. The plastic pipe has excellent corrosion resistance and small friction resistance. Delivery of epoxy resin coated steel pipe is suitable for water, water, water, oil, gas and other medium, PVC plastic pipe for drainage, water, oil, gas and other media delivery.

- Q: How do you calculate the flow rate in stainless steel pipes?

- To calculate the flow rate in stainless steel pipes, you can use the Poiseuille's law or the Darcy-Weisbach equation. These formulas take into account factors such as the pipe diameter, length, viscosity of the fluid, and pressure drop. By plugging in the relevant values, you can determine the flow rate of the fluid through the stainless steel pipes.

- Q: Can stainless steel pipes be used for power plants?

- Yes, stainless steel pipes can be used for power plants. Stainless steel offers excellent corrosion resistance and high-temperature strength, making it suitable for various applications in power plants, including carrying fluids and gases, heat exchangers, and steam distribution systems.

- Q: Are stainless steel pipes suitable for chemical refineries?

- Chemical refineries can rely on stainless steel pipes for their operations. The exceptional corrosion resistance properties of stainless steel make it the perfect choice for handling corrosive substances in these refineries. These pipes demonstrate remarkable chemical resistance, even in harsh and high-temperature environments, which is crucial during the refining process. Furthermore, stainless steel pipes possess great durability and can withstand the high-pressure conditions commonly encountered in refineries. They also exhibit high tensile strength, ensuring the safety and integrity of the entire piping system. In addition, stainless steel pipes are easy to clean and maintain, which is vital for preserving the purity and quality of the refined chemicals. All in all, stainless steel pipes provide a reliable and efficient solution for transporting chemicals in chemical refineries.

Send your message to us

Stainless Steel 304 sheet for exporting only

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords