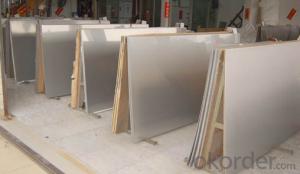

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: Are stainless steel pipes suitable for automotive exhaust systems?

- Yes, stainless steel pipes are suitable for automotive exhaust systems. Stainless steel is a popular choice for exhaust systems due to its excellent resistance to corrosion and high temperatures. It can withstand the harsh conditions of an exhaust system, including exposure to moisture, heat, and chemicals. Stainless steel pipes also have good strength and durability, ensuring they can withstand the vibrations and pressure fluctuations within the exhaust system. Additionally, stainless steel pipes are known for their aesthetic appeal and can enhance the overall look of the vehicle. Overall, stainless steel pipes are a reliable and long-lasting option for automotive exhaust systems.

- Q: What is the difference between 304L and 316L stainless steel pipes?

- 304L and 316L are both types of stainless steel pipes, but they differ in terms of their chemical composition and specific properties. 304L stainless steel is a low carbon variation of 304 stainless steel, which means it has a lower carbon content. This makes it more resistant to sensitization, which is the formation of chromium carbide at grain boundaries, leading to intergranular corrosion. Due to its lower carbon content, 304L stainless steel pipes are commonly used in environments where sensitization is a concern, such as in welding applications or in corrosive environments. On the other hand, 316L stainless steel is an austenitic stainless steel that contains molybdenum, which gives it improved corrosion resistance compared to 304L stainless steel. The addition of molybdenum enhances its resistance to pitting and crevice corrosion, making it suitable for use in more aggressive environments such as marine environments or chemical processing plants. In terms of mechanical properties, 316L stainless steel pipes generally have higher tensile strength and yield strength compared to 304L stainless steel pipes. This makes 316L stainless steel pipes more suitable for applications requiring higher strength and durability. In summary, the main difference between 304L and 316L stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304L stainless steel pipes are more resistant to sensitization, while 316L stainless steel pipes offer higher corrosion resistance, particularly in more aggressive environments. The choice between the two types depends on the specific application requirements and the environment in which the pipes will be used.

- Q: Are stainless steel pipes suitable for food processing?

- Indeed, stainless steel pipes prove to be an excellent choice for food processing purposes. The food industry widely embraces stainless steel owing to its exceptional characteristics and manifold benefits. Primarily, stainless steel pipes exhibit resistance against corrosion, a pivotal factor in food processing. This resistance guarantees that the pipes will not contaminate the food or alter its flavor. Such corrosion resistance arises from the elevated levels of chromium present in stainless steel, which generate a protective oxide layer on the surface. This layer effectively prevents rusting and corrosion. In addition, stainless steel is renowned for its hygienic nature and ease of cleaning, rendering it ideal for food processing applications. The smooth surface of stainless steel pipes minimizes the risk of bacterial growth and simplifies the elimination of potential contaminants. Furthermore, stainless steel is impermeable, meaning it does not absorb or retain odors, flavors, or colors from the food being processed. Moreover, stainless steel pipes boast durability and a long lifespan, which leads to reduced maintenance and replacement costs. They can withstand high temperatures and pressures, making them suitable for various food processing activities such as cooking, boiling, and sterilization. Lastly, stainless steel represents a sustainable and environmentally friendly option. It is entirely recyclable, making it an eco-conscious choice for food processing facilities. In conclusion, stainless steel pipes are highly suitable for food processing due to their corrosion resistance, hygienic properties, durability, and sustainability. They offer a dependable and secure solution for transporting food and maintaining the quality and integrity of the final products.

- Q: Are stainless steel pipes suitable for underground heating systems?

- Indeed, underground heating systems can employ stainless steel pipes as they possess suitability. The reason lies in the fact that stainless steel exhibits remarkable resistance against corrosion and can endure the severe circumstances of subterranean burial. Moreover, this material showcases durability, longevity, and the ability to withstand elevated temperatures and pressures, rendering it an exemplary option for heating systems. Not only that, but stainless steel pipes also offer ease in installation and maintenance, thereby furnishing a dependable and effective resolution for underground heating systems.

- Q: Can stainless steel pipes be laser welded?

- Stainless steel pipes have the capability of being laser welded. Laser welding proves to be an extremely efficient and accurate technique for connecting metals, including stainless steel. This method involves the utilization of a high-powered laser beam to merge and melt the pipe edges together. Due to its capacity to generate robust and long-lasting welds with minimal distortion, laser welding is widely employed in various industries like automotive, aerospace, and construction. The process is especially suitable for stainless steel because it provides exceptional control over the heat input, resulting in a narrow and well-defined weld area. Moreover, laser welding can be automated, making it a financially viable and time-effective solution for joining stainless steel pipes.

- Q: Under what circumstances can the stainless steel pipe be welded by argon arc, and under what conditions can the arc welding be used?

- From the economic point of view and flexibility, arc welding is good, from the efficiency aspect, of course, argon arc welding is higher, the effect is better, and also more mechanized. If it is small batch, it will choose arc welding.

- Q: Can stainless steel pipes be coated for additional protection?

- Yes, stainless steel pipes can be coated for additional protection. Coatings can provide various benefits such as corrosion resistance, improved durability, and enhanced aesthetic appearance. The most commonly used coating for stainless steel pipes is a polymer-based coating, which acts as a barrier against external elements and prevents corrosion. Other types of coatings, such as epoxy or zinc coatings, can also be applied to stainless steel pipes to provide additional protection. The choice of coating depends on the specific requirements and environmental conditions the pipes will be exposed to. Coating stainless steel pipes can help extend their lifespan and ensure optimal performance in various applications, including industrial and residential plumbing systems.

- Q: What is the difference between seamless and EFW stainless steel pipes?

- Seamless and EFW (Electric Fusion Welded) stainless steel pipes are two different types of stainless steel pipes that have distinct characteristics and manufacturing processes. Firstly, seamless stainless steel pipes are manufactured without any welding seams or joints. They are made from a solid cylindrical billet, which is heated and then stretched over a mandrel to create a hollow tube. This process ensures that seamless pipes have a consistent wall thickness and a smooth interior surface, making them ideal for applications that require high-pressure, high-temperature, or corrosive environments. Due to their seamless construction, these pipes offer better strength and durability. On the other hand, EFW stainless steel pipes are created by using a combination of high-frequency electrical current and pressure to weld the edges of two stainless steel sheets or plates together. This fusion welding process forms a continuous seam along the length of the pipe. EFW pipes are typically used for lower-pressure and lower-temperature applications, such as conveying fluids or gases in industrial settings. One key difference between seamless and EFW stainless steel pipes is their manufacturing complexity. Seamless pipes require more intricate and precise manufacturing techniques, resulting in a higher production cost compared to EFW pipes. Additionally, the seamless process allows for a wider range of sizes and thicknesses, while EFW pipes are typically limited in their size options. Another difference lies in the availability of grades and alloys. Seamless stainless steel pipes are available in a wide range of grades and alloys, offering greater flexibility for specific applications. EFW pipes, on the other hand, have a more limited selection of available grades and alloys. In terms of mechanical properties, seamless stainless steel pipes generally have superior strength and corrosion resistance compared to EFW pipes. The absence of welds or joints in seamless pipes reduces the risk of weak points that could be prone to corrosion or failure. In summary, seamless stainless steel pipes are manufactured without any welding seams, offering better strength, durability, and corrosion resistance. They are suitable for high-pressure, high-temperature, or corrosive applications. EFW stainless steel pipes, on the other hand, are created by fusion welding two stainless steel sheets or plates together, making them more suitable for lower-pressure and lower-temperature applications.

- Q: Can stainless steel pipes withstand high temperatures?

- Yes, stainless steel pipes are known for their excellent heat resistance and can withstand high temperatures. The specific temperature range that stainless steel pipes can withstand depends on the grade of stainless steel used. Generally, stainless steel pipes can handle temperatures up to 1200°C (2192°F) without losing their structural integrity. In addition to their high-temperature resistance, stainless steel pipes also exhibit good corrosion resistance, making them suitable for various industrial applications where high temperatures and corrosive environments are present, such as in chemical processing plants, power generation facilities, and automotive exhaust systems.

- Q: What are the dimensions and sizes of stainless steel pipes?

- Stainless steel pipes come in various dimensions and sizes to cater to different industrial and commercial applications. The dimensions and sizes of stainless steel pipes are determined by their nominal diameter (DN) and their schedule or wall thickness. The nominal diameter refers to the approximate internal diameter of the pipe, and it is commonly expressed in inches or millimeters. The most commonly available stainless steel pipe sizes range from 1/8 inch (3.175 mm) up to 48 inches (1219 mm) in nominal diameter. However, larger sizes can be custom-made to meet specific requirements. The schedule or wall thickness of stainless steel pipes is denoted by a schedule number, which indicates the thickness of the pipe's walls. The most common schedules for stainless steel pipes are Sch 5, Sch 10, Sch 40, and Sch 80. The higher the schedule number, the thicker the walls of the pipe. In addition to the dimensions and sizes, stainless steel pipes are also available in various lengths, typically ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). However, custom lengths can also be ordered based on specific project needs. It is worth noting that these dimensions and sizes may vary depending on the standards and specifications set by different countries and industries. Therefore, it is essential to consult the relevant standards or work with a trusted supplier to ensure the accurate dimensions and sizes of stainless steel pipes for a particular application.

Send your message to us

Stainless Steel 304 sheet from China top manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords