Aluminum Window Profiles - Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

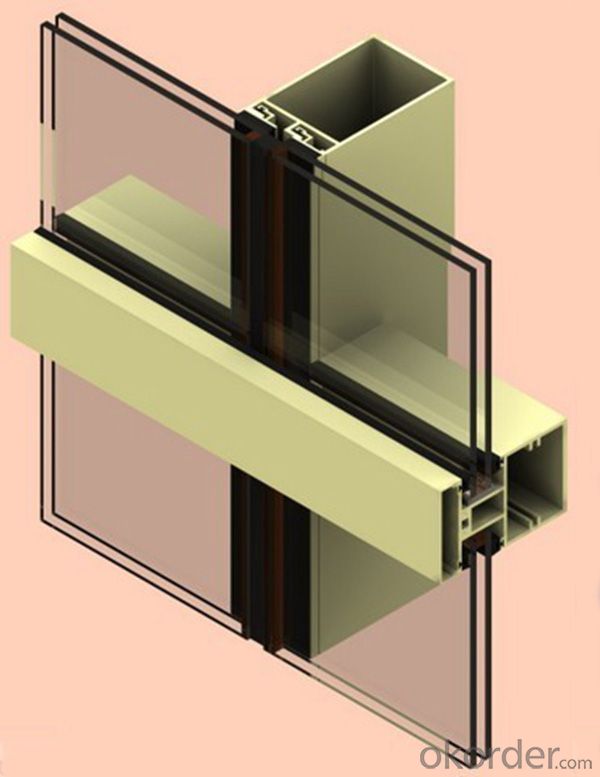

5. Image of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

6. Package and shipping of Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- The surface treatment of the curtain wall aluminum plate is solved by electrostatic spraying, not only the color difference becomes smaller, but also the aluminum plate with various colors can be obtained. Electrostatic spraying can be divided into powder spraying and fluorocarbon spraying. The raw materials of powder spraying are polyurethane, polyurethane resin, epoxy resin, hydroxyl polyester resin and epoxy / polyester resin, which can be made into many colors. The characteristics of powder spraying: spraying equipment manual, automatic hanging type, simple construction, the thickness of the coating is 30 micron, impact resistance, abrasion resistance, corrosion resistance, weather resistance are good, the price cheaper than fluorocarbon coatings.

- Q: Can aluminum profiles be used in the construction of modular healthcare facilities?

- Yes, aluminum profiles can be used in the construction of modular healthcare facilities. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for modular construction. They can be easily assembled, disassembled, and reconfigured, allowing for flexibility in the layout and design of healthcare facilities. Additionally, aluminum profiles can be powder-coated to provide a clean and hygienic surface, which is essential for healthcare environments.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: Which aluminum profile is better here in Guangdong?

- 1 、 aluminum material2, Zhong Wang aluminum3 Asia Aluminum4, Hing Fat aluminum5, the phoenix aluminum aluminum6, the United States and aluminum7, vibration or aluminum8 、 Nanshan aluminum material9, pillars of aluminum10, South South aluminum

- Q: Are aluminum profiles suitable for gym equipment?

- Yes, aluminum profiles are suitable for gym equipment. Aluminum is a lightweight and durable material that can withstand heavy use and provide excellent structural support. Its strength-to-weight ratio makes it ideal for gym equipment as it allows for easy maneuverability while still maintaining stability and durability. Additionally, aluminum is resistant to corrosion, making it suitable for environments with high humidity or moisture levels, such as gyms or fitness centers. The versatility of aluminum profiles also enables the customization of gym equipment to fit specific needs and requirements. Overall, aluminum profiles offer numerous benefits for gym equipment, making them a suitable choice for fitness facilities.

- Q: What are the different surface treatment options available for aluminum profiles?

- Some of the different surface treatment options available for aluminum profiles include anodizing, powder coating, painting, polishing, and brushing.

- Q: This question asks for a list of various fasteners that can be used to connect aluminum profiles to building structures.

- <p>There are several types of fasteners used to attach aluminum profiles to building structures, including: 1. Bolts and Nuts: Commonly used for strong and secure connections. 2. Rivets: Provide a permanent connection by deforming the rivet when installed. 3. Self-tapping Screws: Can be used to create a thread in the aluminum profile without pre-tapping. 4. Adhesives: Used for bonding profiles together, often in conjunction with mechanical fasteners. 5. Welding: Although not a fastener, welding can join aluminum profiles together by melting and fusing the materials. 6. Clamps and Brackets: Used to hold profiles in place temporarily or permanently. 7. Dowels and Pins: Used for alignment and positioning of profiles. Each type of fastener has its specific applications and advantages depending on the structural requirements and design considerations.</p>

- Q: Ask Master: at present domestic industry deep aluminum extrusion production line of domestic manufacturers are also many, but the price is still the production line and abroad have obvious difference, then foreign production lines in what ways do better? Thank you

- The temperature of the extrusion bar and the temperature of the die and the temperature control of the outlet are more accurate. Technically speaking, after all, foreign development is much better than domestic time, from casting alloy ratio to extrusion temperature control, there is still a certain gap between time control.

- Q: What are the different extrusion methods used for aluminum profiles?

- Aluminum profiles can be produced using various extrusion methods. Here are some commonly employed techniques: 1. The most frequently used method is direct extrusion. It involves heating an aluminum billet and forcing it through a die by means of a ram. The aluminum is shaped into the desired form as it passes through the die. Direct extrusion is known for its efficiency and cost-effectiveness. 2. Indirect extrusion, on the other hand, requires the billet to remain stationary while the die moves towards it. The die pushes the aluminum through the stationary billet, resulting in the desired shape. This method is often favored for intricate shapes or when precision is crucial. 3. Impact extrusion employs a punch to forcefully drive the aluminum billet into a die cavity. The high impact causes the material to flow into the die and take on its shape. This method is commonly used for manufacturing hollow parts or tubes. 4. Hydrostatic extrusion relies on the use of a fluid, such as oil or water, to pressurize the billet and guide it through a die. The elevated fluid pressure enables greater control and precision in shaping the aluminum. Hydrostatic extrusion is typically chosen for producing high-quality, strong aluminum profiles. 5. Cold extrusion takes place at room temperature, with the aluminum billet being extruded without heating. The lower temperature contributes to increased strength and improved surface finish. Cold extrusion is popular for creating small, intricate aluminum profiles. Each of these extrusion methods offers its own set of advantages and is suitable for different applications. Factors such as profile complexity, desired strength, surface finish requirements, and cost considerations play a role in determining the most suitable method.

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Aluminum Window Profiles - Silver Finish Anodized Aluminum Profile for Glass Door Shower Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords