Aluminum Profiles Windows Doors - Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

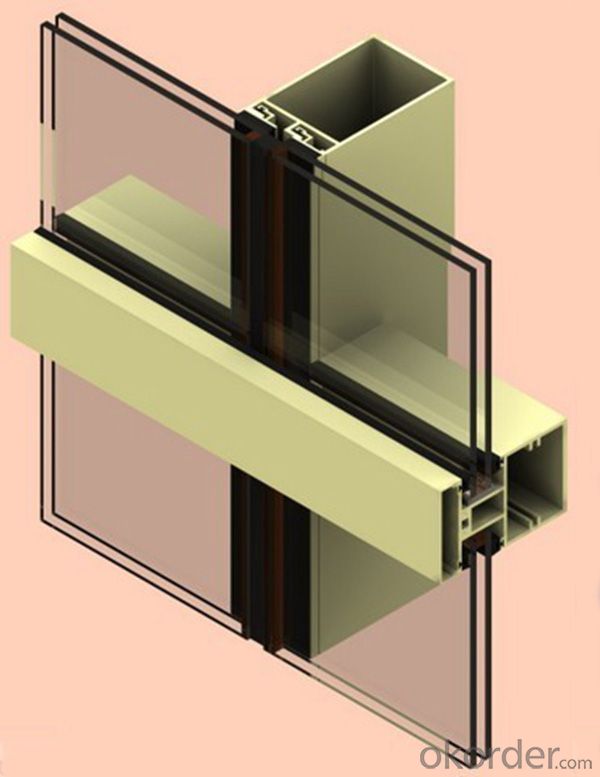

2. Application of Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

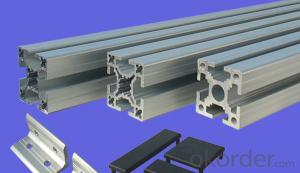

5. Image of Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

6. Package and shipping of Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: What is the price of aluminum paint spray?

- It can also be calculated according to the weight. Do you have more aluminum profiles to be painted?

- Q: Can aluminum profiles be used for framing mirrors?

- Yes, aluminum profiles can be used for framing mirrors. Aluminum is a versatile and lightweight material that provides a sleek and modern look to any mirror frame. It is commonly used in various industries, including architecture and interior design, due to its durability, corrosion resistance, and ease of customization. Aluminum profiles come in a variety of shapes and finishes, allowing for endless design possibilities to match any style or decor. Additionally, aluminum frames are easy to install and maintain, making them a popular choice for framing mirrors in both residential and commercial settings.

- Q: Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: What are the thermal properties of aluminum profiles?

- Aluminum profiles have excellent thermal properties. They have high thermal conductivity, allowing heat to be transferred quickly and efficiently. They also have a low coefficient of thermal expansion, meaning they can withstand temperature changes without significant distortion or damage. Additionally, aluminum profiles have good heat dissipation capabilities, making them suitable for applications requiring heat management, such as in electronic devices or heat sinks.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: This question asks for the proper and safe method of installing aluminum profiles, which are commonly used in construction and manufacturing.

- <p>To install aluminum profiles correctly and safely, follow these steps: 1. Plan the layout and measure the required lengths accurately. 2. Use appropriate cutting tools to cut the profiles to size, ensuring a clean edge. 3. Apply protective gloves and eyewear when handling aluminum profiles to avoid injury. 4. Use the correct fasteners, such as screws or bolts, compatible with the aluminum profiles. 5. Ensure the profiles are securely fastened and aligned properly. 6. Check for any sharp edges or burrs after installation and smooth them out to prevent injury. 7. Always follow the manufacturer's guidelines and safety precautions. Proper installation and safety measures will ensure the longevity and stability of the aluminum profiles.</p>

- Q: What is aluminum profile opening mold, I want to process a batch of aluminum profiles, the other side to open mold fees also expensive, then I can open the mold of things? I don't know the hero for a favor

- Aluminum production process is actually like toothpaste, the liquid aluminum from a specific shape of the mouth squeezed out, cool after becoming a profile, mold that is to do that exit......

- Q: Are aluminum profiles suitable for constructing energy-efficient building systems?

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight, strong, and have excellent thermal conductivity, which can be advantageous in heat transfer management. Aluminum profiles can be used in the construction of windows, doors, and facades, which are critical for insulation and energy conservation. Additionally, their malleability allows for precise engineering to minimize heat loss and maximize energy efficiency. Proper insulation and sealing techniques can further enhance the energy efficiency of buildings constructed with aluminum profiles.</p>

- Q: I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

- Q: What are the weatherproofing properties of aluminum profiles?

- Aluminum profiles have excellent weatherproofing properties due to their inherent characteristics and manufacturing processes. Aluminum is a naturally corrosion-resistant material, which means it can withstand exposure to various weather conditions without deteriorating or rusting. It forms a thin layer of oxide on its surface, providing an additional barrier against moisture and preventing further corrosion. Additionally, aluminum profiles can be further enhanced with various weatherproofing techniques. One common method is anodizing, where the aluminum surface is treated with an electrolytic process to create a thicker and more durable oxide layer. This not only improves the weather resistance but also enhances the profile's resistance to scratching and wear. Furthermore, aluminum profiles can be coated with different protective finishes, such as powder coating or liquid paint. These coatings not only provide an aesthetic appeal but also serve as an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers superior durability and resistance to fading, chipping, and cracking. Moreover, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements create a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They help maintain a comfortable indoor environment, reduce energy consumption, and enhance the overall weatherproofing performance of the aluminum profiles. Overall, the weatherproofing properties of aluminum profiles make them a popular choice for various applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and available protective coatings make them a reliable and durable option for both residential and commercial projects.

Send your message to us

Aluminum Profiles Windows Doors - Anodize SS Brush Polished Modular Aluminum Profile for Kitchen Cabinet Door Frame and Handles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords