Custom Powder Coated Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Application of Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

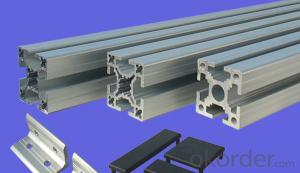

5. Image of Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

6. Package and shipping of Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Can aluminum profiles be used in the construction of retail displays?

- Yes, aluminum profiles can be used in the construction of retail displays. Aluminum is a versatile and lightweight material that is commonly used in various industries, including construction and retail. It offers several advantages for retail displays, such as durability, corrosion resistance, and ease of customization. Aluminum profiles can be easily shaped and fabricated to create different types of retail displays, such as shelving units, display stands, signage frames, and product showcases. These profiles can be extruded into different shapes and sizes, allowing for flexibility in design and functionality. Additionally, aluminum profiles can be finished with various surface treatments, such as anodizing or powder coating, to enhance their appearance and provide a protective layer against scratches and wear. This allows retail displays to maintain their aesthetic appeal and withstand the demands of a retail environment. Furthermore, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for retail displays. It can be easily recycled without losing its properties, reducing the environmental impact of construction and retail industries. In summary, aluminum profiles are a suitable and practical choice for the construction of retail displays. They offer durability, versatility, and customization options while being lightweight and environmentally friendly.

- Q: How do you prevent galvanic corrosion with aluminum profiles?

- To prevent galvanic corrosion with aluminum profiles, there are several steps that can be taken: 1. Use compatible materials: It is important to select materials that are compatible with aluminum to avoid galvanic corrosion. Avoid coupling aluminum profiles with dissimilar metals, such as copper, brass, or steel, as these combinations can accelerate the corrosion process. 2. Apply protective coatings: Applying a protective coating, such as anodizing or painting, can provide a barrier between the aluminum profiles and the surrounding environment. Anodizing creates a durable oxide layer on the surface of aluminum, which enhances its corrosion resistance. Painting with suitable corrosion-resistant paints can also provide an effective barrier against galvanic corrosion. 3. Insulate dissimilar metals: If it is necessary to use dissimilar metals in conjunction with aluminum profiles, it is crucial to insulate them from direct contact. This can be achieved by using gaskets, insulating materials, or non-conductive fasteners to separate the metals and prevent the electrical contact that causes galvanic corrosion. 4. Regular maintenance and cleaning: Regular cleaning and maintenance of aluminum profiles can help prevent galvanic corrosion. Removing any accumulated dirt, debris, or other contaminants from the surface can minimize the chances of corrosion initiation. 5. Control the environment: Controlling the environment in which aluminum profiles are used can also play a significant role in preventing galvanic corrosion. Avoid exposing aluminum to environments with high humidity, saltwater, or acidic conditions, as these can accelerate corrosion. Additionally, maintaining proper ventilation and moisture control can help minimize the risk of corrosion. By following these preventive measures, it is possible to significantly reduce the risk of galvanic corrosion and ensure the longevity and performance of aluminum profiles.

- Q: Aluminum 3100-6063-T5, please

- Aluminum in the industry according to material characteristics, such as hardness, strength, corrosion resistance and other categories, there are 8 main series, each series with 4 figures as a brand, and subdivided into many types1 series industrial pure aluminum: 1XXX2 series superhard aluminum material: 2XXX3 series easy cutting aluminum material: 3XXX4 series easy cutting aluminum material: 4XXX5 series magnesium aluminum alloy: 5XXX6 series anodic oxidation and corrosion resistant aluminum: 6XXX7 Series aviation ultra hard aluminum: 7XXX8 series: 8XXXYou say 3100-6063-T5 may contain the 3 and 6 series, easy to cut and resistant to corrosion,.T5 indicates hardness levels

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: Are aluminum profiles suitable for use in roofing or wall systems?

- <p>Yes, aluminum profiles are commonly used for both roofing and wall systems due to their durability, corrosion resistance, and lightweight properties. They offer a modern aesthetic and can be easily integrated into various architectural designs. Aluminum profiles are also known for their strength and flexibility, allowing for the creation of complex shapes and structures. Additionally, they require minimal maintenance and can withstand harsh weather conditions, making them a popular choice for construction projects.</p>

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Of course, you only choose the quality of aluminum, as far as possible to choose the hardness of high bar, 5052, 5056, 6082, 7075 and so on are high strengthAluminium alloy。Our common 6063-T5 material, the door and window material is the material.

- Q: This question asks for guidance on ensuring a safe and efficient installation process for aluminum profiles.

- <p>To ensure a safe and efficient installation process for aluminum profiles, follow these steps: Use appropriate safety gear such as gloves and goggles. Ensure the profiles are of high quality and fit for purpose. Plan the installation carefully, marking out the positions accurately. Use the correct tools for cutting and drilling, and ensure they are sharp and well-maintained. Install the profiles in a clean, dry environment to prevent damage. Follow the manufacturer's guidelines for assembly and use the correct fasteners. Regularly inspect the installation for any signs of wear or damage. By adhering to these practices, you can ensure a safe and efficient installation process.</p>

- Q: How do aluminum profiles perform in electrical insulation applications?

- Aluminum profiles do not perform well in electrical insulation applications as aluminum is a good conductor of electricity. It is not suitable for providing insulation and can potentially pose a risk of electrical conductivity.

- Q: Are aluminum profiles suitable for constructing energy-efficient building systems?

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight, strong, and have excellent thermal conductivity, which can be advantageous in heat transfer management. Aluminum profiles can be used in the construction of windows, doors, and facades, which are critical for insulation and energy conservation. Additionally, their malleability allows for precise engineering to minimize heat loss and maximize energy efficiency. Proper insulation and sealing techniques can further enhance the energy efficiency of buildings constructed with aluminum profiles.</p>

- Q: Are aluminum profiles suitable for modular office systems?

- Yes, aluminum profiles are suitable for modular office systems. Aluminum is a lightweight and versatile material that offers various advantages for modular office systems. Firstly, aluminum profiles are highly durable and have excellent strength-to-weight ratio, making them suitable for supporting various structures and office components. They can withstand heavy loads and provide stability to the modular system. Secondly, aluminum profiles are corrosion-resistant, which is crucial for office environments that may have moisture or humidity. This ensures that the modular office system will maintain its integrity and appearance over time. Additionally, aluminum profiles offer design flexibility, allowing for customization and adaptation to different office layouts and requirements. They can be easily modified, cut, and assembled to create a modular system that meets specific needs. This flexibility also allows for future expansion or reconfiguration of the office space. Furthermore, aluminum profiles are environmentally friendly, as they are recyclable and have a low carbon footprint compared to other materials. This aligns with the growing trend of sustainable and eco-friendly office design. In conclusion, aluminum profiles are highly suitable for modular office systems due to their durability, corrosion resistance, design flexibility, and environmental benefits.

Send your message to us

Custom Powder Coated Aluminum Alloy Profiles for Kitchen Cabinet Frame Door Frames

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords