Double Glazed Door Handles

Double Glazed Door Handles Related Searches

Door Handles Nz Security Screen Door Handles Industrial Door Handles And Locks Replacement Upvc Door Handles Glass Shower Door Hooks Bi Fold Doors Double Hook Mortise Lock Latch Handle Door Set Double Hanging Egg Chair Second Hand Garden Sheds Decorative Interior Doors Door Making Machine Front Entry Wood Doors Front Entry Doors Second Hand Sun Loungers Glass Pendant Chandelier Ready Made Window Blinds Mechanical Door Closer Herculite Sliding Doors External Doors Interior Composite Doors French Door Hooks Horizontal Window Blinds Exterior Door Hooks Double Flange Bend Pleated Screen Door Lamp Post Replacement Glass Hand Held Sharpening Stone Shower Door Towel Hook French Door Retaining HooksDouble Glazed Door Handles Supplier & Manufacturer from China

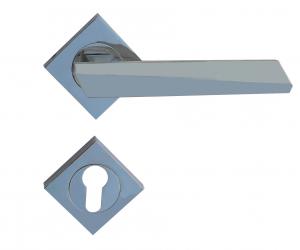

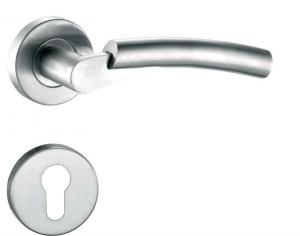

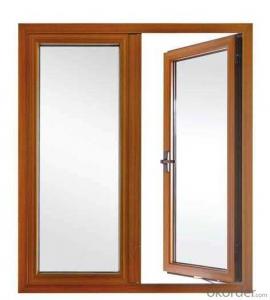

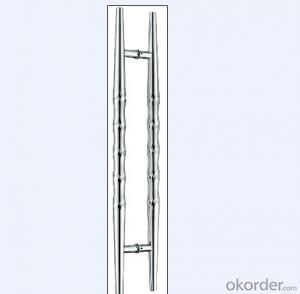

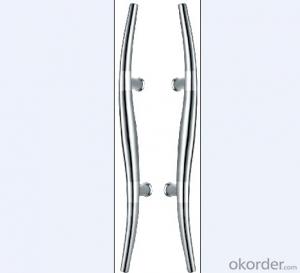

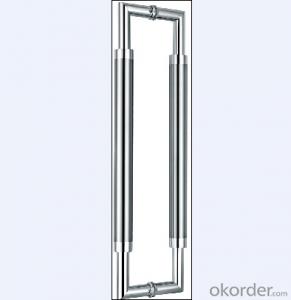

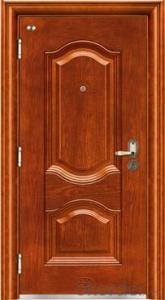

Double Glazed Door Handles are a type of door handle specifically designed for double glazed doors, providing a secure and aesthetically pleasing solution for entranceways. These handles are engineered to withstand the unique demands of double glazed doors, ensuring durability and functionality in various settings. They are widely used in residential, commercial, and industrial applications, making them an essential component for any door that requires a high level of security and insulation. The versatility of double glazed door handles allows them to be used in a variety of environments, from homes to office buildings and beyond.Okorder.com is a leading wholesale supplier of Double Glazed Door Handles, offering a vast inventory to cater to the needs of various clients. Our extensive range of products ensures that we can provide the perfect solution for any project, whether it's a small home renovation or a large-scale commercial development. As a reliable source for double glazed door handles, we pride ourselves on delivering high-quality products at competitive prices, making us the go-to destination for contractors, builders, and homeowners alike.

Hot Products