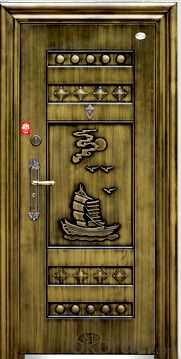

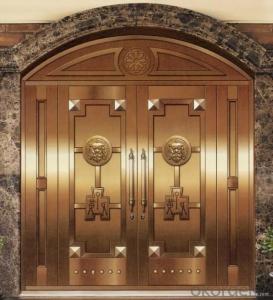

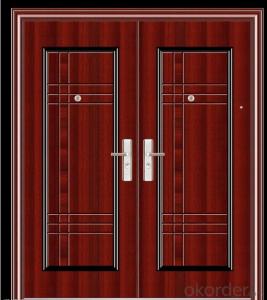

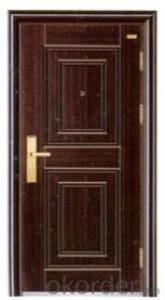

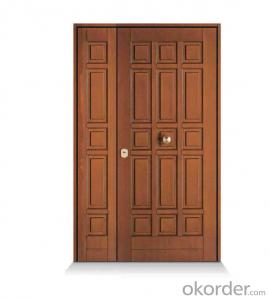

Prime High - End Galvanized Steel Door In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detail Specifications

1:Steel sheet of door panel

0.3 ~ 1.0mm cold rolled steel sheet

2:Steel sheet of door frame

0.7 ~ 2.0mm cold rolled steel sheet

3:Frame outer sizes (HxW)

2050 x 860mm / 960mm, or customized size

4:Thickness of the door leaf

50 / 70 / 90mm

5:Opening direction

Left inside / Left outside / Right inside / Right outside

6:Inner filling material

Honeycomb paper / Rock wool / PU foam

7:Rubber sealed:Double-layer rubber sealed strip around the door

8:Door sill-High quality stainless steel threshold

9:Doorbell--Invisible alarm doorbell ( both practical and beautiful)

10:Peephole-Wideangle peephol

11:Hinges-Galvanized steel hinges

12:Surface treatment

Bright, lustrous and durable appearance, the door surface via acid cleaning phosphorizing antirust processing

Heat-transfer printing on surface: looks like the natural wooden grain. Or powder coating on surface

13:With high quality burglarproof lock;ABC lock-set with 13 lock points

- Q: Broken bridge aluminum alloy doors and windows, aluminum content can refer to the data?

- Look at what manufacturers, consult manufacturers like

- Q: Consult steel doors and windows are good or aluminum doors and windows sound insulation good?

- First look at you personally love aluminum or steel, the real sound insulation is good or good plastic, but not durable. Aluminum insulation noise is a little bit worse than plastic, but more durable than steel. Want to do the best steel, do authentic, and now many are half genuine half adulterated because you are not a professional you can not tell. But the focus is the price is a bit high. Made of aluminum alloy medium double glass noise on it. I am definitely not blind, because I have worked in this industry for more than a decade. Broken bridge aluminum is a series of aluminum, not suitable for the balcony. Hope to help you.

- Q: What are the names of aluminum alloy doors and windows?

- Sliding window required materials: side seal, slippery, down, pipe jacking, pipe, cover, hook enterprises, customs enterprises above, below, pressure line. Flat window need: outside the box material, in the material, the fan material pressure line

- Q: If so, what is the best way to do that? What is the best type of paint to use on metal doors?

- Not necessary to remove the old. Just use a Liquid sandpaper to clean it well. Available at all paint suppliers. Manually sand any bare or rust spots, (although may be aluminum), and use a metal base coat. There are many paints for metal. Check with your supplier.

- Q: Home titanium magnesium alloy door is good or solid wood door good

- Do you say that the titanium-magnesium alloy door is the ecological door? In fact, the ecological door is only niche market, in fact, or some people like, quite personality ... ...

- Q: how to put wood on a metal garage door?

- If you are planning to start on your woodworking project, this isn't something you should use, it's something that you would be insane not to.

- Q: How do you cut off about one inch of the bottom of a metal door? What kind of tool do you need?

- I wouldn't recommend you even try it. Most metal doors aren't solid inside it will ruin the door.

- Q: What is the use of aluminum alloy door light?

- Light is the door material

- Q: Hello alllt; I have this great white metal security door that has gotten its beating with natural weathering. so I would like to paint it black with a heavy gloss (saw many black doors online and they all look great) my problem is that my door isnt wood it made up of metal or aluminum (not sure which type) but the molding is great and i would like to leave a flush finish on it with no drips or no spots un-touch. but with so many rollers @ home depot which one do I chose??? Never would I have thought painting my metal door be time consuming figuring out which brush or roller 2 choose.thanks!!

- Yes, I would definitely rough the door up a bit and remove all imperfections, prime/seal it. Then use a low nap roller, brushes tend to leave brush marks. A roller will make everything look smooth. Spray paint is also a good option as long as a good primer/sealer is applied. Most importantly a paint job is only as good as it's preparation-make sure all rust and imperfections are removed from the metal before priming and painting. Good Luck!

- Q: Kitchen aluminum door deformation how to repair their own

- Do not have to find someone else to change it hee hee

Send your message to us

Prime High - End Galvanized Steel Door In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 set

- Supply Capability:

- 2000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches