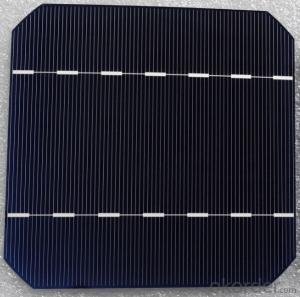

Silicone Wafer Solar Panel - High Quality A Grade Monocrystalline Solar Cell 5V 17.4%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hot sale solar cell

1.16.8%~18.25% high efficiency

2.100% checked quality

3.ISO9001/ISO14001/TUV/CE/UL

4.stable performance

We can offer you the best quality products and services, don't miss !

POLY6'(156*156)

Polycrystalline Silicon Solar cell

Physical Characteristics

Dimension: 156mm×156mm±0.5mm

Diagonal: 220mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating (silicon nitride); Aluminum back surface field;

1.5mm wide bus bars; 2.0mm wide soldering pads;

Distance between bus bars: 51mm . Distance between bus bars :51mm .

Electrical Characteristics

Efficiency(%) | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 | 16.80 | 16.60 | 16.40 | 16.20 | 16.00 | 15.80 | 15.60 |

Pmpp(W) | 4.33 | 4.29 | 4.24 | 4.19 | 4.14 | 4.09 | 4.04 | 3.99 | 3.94 | 3.90 | 3.86 | 3.82 |

Umpp(V) | 0.530 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.514 | 0.511 | 0.509 | 0.506 | 0.503 | 0.501 |

Impp(A) | 8.159 | 8.126 | 8.081 | 8.035 | 7.990 | 7.938 | 7.876 | 7.813 | 7.754 | 7.698 | 7.642 | 7.586 |

Uoc(V) | 0.633 | 0.631 | 0.628 | 0.625 | 0.623 | 0.620 | 0.618 | 0.617 | 0.615 | 0.613 | 0.611 | 0.609 |

Isc(A) | 8.709 | 8.677 | 8.629 | 8.578 | 8.531 | 8.478 | 8.419 | 8.356 | 8.289 | 8.220 | 8.151 | 8.083 |

MONO5'(125*125mm)165

Monocrystalline silicon solar cell

Physical Characteristics

Dimension: 125mm×125mm±0.5mm

Diagonal: 165mm±0.5mm

Thickness(Si): 200±20 μm

Front(-) Back(+)

Blue anti-reflecting coating(silicon nitride); Aluminum back surface field;

1.6mmwide bus bars; 2.5mm wide soldering pads;

Distance between bus bars: 61mm . Distance between bus bars :61mm .

Electrical Characteristics

Efficiency(%) | 19.40 | 19.20 | 19.00 | 18.80 | 18.60 | 18.40 | 18.20 | 18.00 | 17.80 | 17.60 | 17.40 | 17.20 |

Pmpp(W) | 2.97 | 2.94 | 2.91 | 2.88 | 2.85 | 2.82 | 2.79 | 2.76 | 2.73 | 2.70 | 2.67 | 2.62 |

Umpp(V) | 0.537 | 0.535 | 0.533 | 0.531 | 0.527 | 0.524 | 0.521 | 0.518 | 0.516 | 0.515 | 0.513 | 0.509 |

Impp(A) | 5.531 | 5.495 | 5.460 | 5.424 | 5.408 | 5.382 | 5.355 | 5.328 | 5.291 | 5.243 | 5.195 | 4.147 |

Uoc(V) | 0.637 | 0.637 | 0.636 | 0.635 | 0.633 | 0.630 | 0.629 | 0.629 | 0.628 | 0.626 | 0.626 | 0.625 |

Isc(A) | 5.888 | 5.876 | 5.862 | 5.848 | 5.839 | 5.826 | 5.809 | 5.791 | 5.779 | 5.756 | 5.293 | 5.144 |

FAQ:

Q:How can i get some sample?

A:Yes , if you want order ,sample is not a problem.

Q:How about your solar panel efficency?

A: Our product efficency around 17.25%~18.25%.

Q:What’s the certificate you have got?

A: we have overall product certificate of ISO9001/ISO14001/CE/TUV/UL

- Q: What is the role of back contact in solar silicon wafers?

- The role of back contact in solar silicon wafers is to provide electrical connection and support for the flow of current generated by the photovoltaic cells. It acts as a conductive layer that allows the captured solar energy to be efficiently transferred to external circuitry for use or storage. Additionally, it helps in maintaining the structural integrity of the wafer and protects the sensitive layers of the solar cell from external factors such as moisture and physical damage.

- Q: Why do you want to make the wafer bigger? The bigger the better, why?

- So the price of a light on the CCD. Because the yield is very low. Astronomical telescopes or military reconnaissance equipment used on the larger size of CCD (such as 4, 8 inches or even 12 inches CCD) is simply astronomical. Looking for a piece of silicon wafer that is close to zero defect is probably a vast project. And the speed of the chip is also affected by the area. The larger the area, the greater the span of the wiring, the greater the frequency of interference and signal

- Q: How are solar silicon wafers affected by humidity and moisture?

- Solar silicon wafers are negatively affected by humidity and moisture. Exposure to high humidity or moisture can cause corrosion and oxidation on the surface of the wafers, which can impair their performance and efficiency. Moisture can also lead to the formation of water droplets or films on the surface, creating a barrier that reduces the amount of sunlight absorbed by the wafers. Additionally, humidity can increase the risk of electrical leakage and insulation failure in the solar cells. Therefore, it is crucial to protect solar silicon wafers from excessive humidity and moisture to maintain their optimal functioning.

- Q: How are solar silicon wafers cleaned and maintained?

- Solar silicon wafers are cleaned and maintained through a multi-step process. First, any loose dirt or debris is removed by gently brushing or rinsing the surface. Next, a mild detergent or specialized cleaning solution is applied to remove stubborn dirt or oily residues. The wafers are then rinsed with deionized water to ensure no residue is left behind. Finally, the wafers are dried using clean, lint-free cloths or by air-drying. Regular inspections and maintenance, such as checking for any cracks or damages, are also essential to ensure optimal performance of the solar silicon wafers.

- Q: How are solar silicon wafers tested for quality control?

- Solar silicon wafers are tested for quality control through a series of rigorous evaluations. These tests typically include visual inspections to detect any physical defects, such as cracks or impurities. Additionally, electrical measurements are conducted to assess the wafers' performance and efficiency. This may involve assessing parameters like resistivity, carrier lifetime, and dark current. Finally, wafers are subjected to optical measurements to analyze their reflectance, transmittance, and surface texturing. These comprehensive quality control tests ensure that only high-quality and reliable solar silicon wafers are used in the production of solar cells and modules.

- Q: How are solar silicon wafers connected in a solar module?

- Solar silicon wafers are typically connected in a solar module through a process called soldering. Thin metal strips, known as busbars, are soldered onto the front and back surfaces of the silicon wafers. These busbars are responsible for collecting the electrical current generated by the individual wafers. The wafers are then interconnected by soldering them to these busbars, creating a series of connected cells within the module. This interconnection allows for efficient flow of electricity from the solar cells to the external circuitry.

- Q: How do solar silicon wafers contribute to the electrification of remote areas?

- Solar silicon wafers contribute to the electrification of remote areas by being the primary component of solar panels. These panels harness solar energy and convert it into electricity, providing a sustainable and renewable source of power. In remote areas where traditional electricity grids are absent or unreliable, solar panels with silicon wafers can be deployed to generate clean energy and bring electricity to communities that would otherwise be without it.

- Q: How is the wafer appearance caused? The performance of the chip half white, a class of black! Seek help!

- You first check the silicon wafer TTV, as well as doping concentration distribution.

- Q: Are all solar silicon wafers the same color?

- No, solar silicon wafers can come in different colors depending on their manufacturing processes and the specific materials used.

- Q: Can solar silicon wafers be used in solar-powered electric fences?

- Yes, solar silicon wafers can be used in solar-powered electric fences. These wafers are commonly used in solar panels to convert sunlight into electricity, which can then be used to power various devices, including electric fences. By utilizing solar silicon wafers, solar-powered electric fences can operate independently from the grid, making them more eco-friendly and cost-effective.

Send your message to us

Silicone Wafer Solar Panel - High Quality A Grade Monocrystalline Solar Cell 5V 17.4%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords