Scaffolding System Ringlock Scaffold Vertical

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Scaffolding System: | Material: | Diameter: | |||

| Surface: | PacKing: |

Packaging & Delivery

| Packaging Detail: | Pallets or As Customer's Requirements |

| Delivery Detail: | 30Days |

Specifications

1.Manufacturer

2.Custom Made: Available

3.Material: Q235 or Q345

4.Surface: Galvanized or Painted

Details

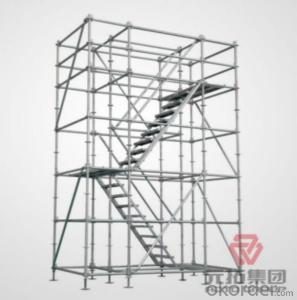

Ring Lock Scaffolding System

OEM service is available

Scaffolding System: Ringlock Scaffolding System

Material: Q235 or Q345

Surface Treatment: Galvanized or Painted or HDG or Powder Coated

Packing: Pallets or As Customer's Requirements

Delivery Time: 30 Days

Auto Welding Machine

A full set of ringlock scaffolding parts offered

Simple and officient to assemble

Specification

| Item Name | Cuplock Scaffolding | |

| Brand Name | Queen | |

| Raw Material | Q235 /Q345steel Grade | |

| Components | Standard.Ledger .Diagonal brace. Top/Bottop Cup/ Ledge Blade | |

| Surface finish | Electric Galvanized/HDG/Powder coated | |

| Size | Pipe size:48.3mm | |

| Thickness:3.25mm | ||

| Usage | Widely used in Bridge .Tunnel.Peterifaction.Shipbuilding .railway,Airport. Dock Industry and Civil Building | |

| Packing | By Steel pallet or bulk | |

- Q: Can steel props be used in shopping mall construction?

- Indeed, shopping mall construction can make use of steel props. These props, also referred to as adjustable steel props or steel shoring props, find frequent application within the construction sector for their ability to provide temporary support to structures. Their usage is particularly prevalent in the construction of multi-story buildings, such as shopping malls, where added reinforcement is necessary to bear heavy loads and cater to the varying stages of construction. The versatility of steel props lies in their adjustable height, rendering them suitable for a range of construction requirements. By design, these props ensure stability and safety to the structure, while their installation, maintenance, and removal are easily accomplished as per need. All in all, steel props stand as a dependable and frequently employed solution within the realm of shopping mall construction.

- Q: Why subway steel support axial force value

- The main reasons are as follows: 1. The deformation of foundation pit is too large;2, caused by high temperature;Generally, the foundation pit is supported by continuous wall (pile) and steel support. Support axial force monitoring, monitoring the foundation pit in the construction process of the support axial force changes, to avoid the bearing axial force beyond the design strength of the support failure caused by the instability of the whole support system.

- Q: Are steel props suitable for supporting mezzanine floors?

- Mezzanine floors can be supported effectively by steel props. Known as adjustable steel columns or steel shores, these props are robust and durable, capable of withstanding substantial weight. They are commonly utilized in construction projects to offer temporary or permanent support to various structures, including mezzanine floors. Mezzanine floors are intermediate floors constructed between the main floors of a building, typically used to create additional space or storage. To ensure the safety and stability of the structure, these floors necessitate strong and reliable support. Steel props are ideal for this purpose due to their strength, load-bearing capacity, and adjustable height feature. Steel props possess the ability to be effortlessly adjusted to attain the desired height, making them versatile and suitable for a range of mezzanine floor heights. Moreover, they can be easily installed and dismantled, providing flexibility and facilitating easy reconfiguration of the mezzanine floor layout. In addition to their strength and adjustability, steel props exhibit resistance to fire, rot, and corrosion. This renders them a dependable choice for supporting mezzanine floors in various environments, encompassing industrial, commercial, and residential settings. Nevertheless, it is crucial to seek guidance from a structural engineer or construction professional to ensure compliance with the specific design and installation requirements of the mezzanine floor. Factors such as load capacity, spacing, and bracing requirements will be taken into account to determine the appropriate size and quantity of steel props required for optimal support. To summarize, steel props represent a suitable and dependable option for supporting mezzanine floors. Their strength, adjustability, and ability to withstand various environmental factors make them an ideal choice for ensuring the stability and safety of mezzanine floor structures.

- Q: Can steel props be used for supporting temporary residential structures?

- Steel props are capable of supporting temporary residential structures. These props, also referred to as adjustable steel props or steel acrow props, are widely employed in construction projects to offer temporary support to structures. They are designed to withstand heavy loads and provide stability during construction or renovation activities. When it comes to temporary residential structures like mobile homes, portable cabins, or temporary shelters, steel props can serve as an effective solution. They can be easily adjusted to the desired height and deliver the necessary support for the structure. Steel props possess strength, durability, and a high load-bearing capacity, making them suitable for a range of temporary residential structures. Nevertheless, it is crucial to ensure the proper installation and adherence to the specific requirements of the structure when using steel props. Seeking professional advice and expertise is essential to ascertain the appropriate size, number, and placement of steel props, guaranteeing the safety and stability of the temporary residential structure. Moreover, routine inspections and maintenance must be conducted to ensure that the steel props remain in good condition and continue to provide the necessary support. Overall, steel props can be deemed a dependable choice for supporting temporary residential structures; however, meticulous planning, installation, and maintenance are pivotal to ensure their effectiveness and safety.

- Q: How do you transport steel props?

- There are several factors to consider when transporting steel props in order to ensure their safe and efficient transportation. Here are some guidelines to follow: 1. Prior to transportation, it is crucial to thoroughly inspect the steel props. Check for any damages or defects that could compromise their stability during transportation. Additionally, ensure that the props are properly cleaned and free from any debris that may cause harm or damage. 2. To safeguard the steel props during transportation, it is advisable to securely package them. This can be achieved by using appropriate packaging materials such as bubble wrap, foam, or cardboard boxes. It is important to choose packaging that can withstand potential impacts during transit. 3. When loading the steel props onto a vehicle, it is essential to ensure proper securing. Utilize suitable lifting equipment, such as cranes or forklifts, to handle the props safely. Securely fasten the props to prevent any movement or shifting during the transportation process. 4. Select a suitable method of transportation based on the quantity and size of the steel props. For smaller quantities, a van or truck equipped with proper tie-downs can be utilized. For larger quantities, flatbed trucks or shipping containers may be necessary. Compliance with all local transportation regulations and obtaining any required permits is essential. 5. Once the steel props are loaded onto the vehicle, they should be secured using straps, chains, or other appropriate restraints. Ensure that the props are evenly distributed on the vehicle and properly fastened to prevent any movement or potential damage. 6. During the unloading process at the destination, exercise the same precautions as during loading. Employ proper lifting equipment and ensure a safe and controlled unloading process. Keep in mind that the specific transportation requirements for steel props may vary depending on their size, weight, and any local regulations. It is always advisable to consult transportation professionals or seek guidance from the manufacturer or supplier of the steel props for specific instructions and recommendations.

- Q: Can steel props be used for temporary support in industrial facilities?

- Yes, steel props can be used for temporary support in industrial facilities. Steel props are commonly used in construction and engineering projects for temporary support of structures, including industrial facilities. They provide stability and strength, ensuring the safety of workers and the integrity of the structure during construction or renovation.

- Q: What are the advantages of using steel props?

- Using steel props in construction projects has several advantages. Firstly, they are highly durable and robust, designed to withstand heavy loads and provide strong support to structures. This makes them ideal for temporary shoring and supporting applications. Secondly, steel props offer adjustability, allowing for flexibility in height and position. Their telescopic design enables easy extension or retraction to fit different heights and accommodate variations in construction levels. This not only enhances their versatility but also saves time and effort in setting up and dismantling. Additionally, steel props are easy to install and dismantle, making them highly efficient. They require minimal tools and equipment, reducing labor costs and construction time. This makes them an ideal choice for temporary structures or projects with tight schedules. Moreover, steel props have a high load-bearing capacity, ensuring the safety and stability of the structure. Their strong and sturdy construction allows them to support heavy loads, making them suitable for use in various applications such as formwork, scaffolding, and trench support. Furthermore, steel props are reusable, offering a cost-effective solution. Their durability and resistance to wear and tear enable them to be used multiple times, reducing the need for frequent replacements and saving money in the long run. Lastly, steel props provide excellent stability and support to structures, minimizing the risk of accidents or structural failures. Their rigid construction ensures that the supported structure remains secure and level, providing peace of mind to construction workers and enhancing overall safety on the worksite. In conclusion, the advantages of using steel props in construction include durability, adjustability, ease of installation and dismantling, high load-bearing capacity, reusability, and stability. These qualities make them a reliable and efficient choice for temporary shoring and supporting applications in construction projects.

- Q: What are the safety precautions to be taken while using steel props?

- To ensure the safety of workers and the stability of the supported structure, it is important to take several safety precautions when using steel props. These precautions include: 1. Inspection of props: It is crucial to thoroughly examine steel props before use to identify any signs of damage or defects. This includes checking for cracks, deformities, or any other issues that could compromise their structural integrity. Damaged props should not be used and must be replaced or repaired. 2. Correct installation: Proper installation of steel props is essential and should be done according to the manufacturer's instructions. This involves securely connecting the props to the supported structure, ensuring proper alignment and tightening. Additionally, props should be placed on stable and level ground to prevent instability or collapse. 3. Load capacity consideration: Each steel prop has a specified load capacity that should not be exceeded. Careful calculation and distribution of the load is necessary to avoid overloading the props. Exceeding the load capacity can result in structural failure and potential accidents. 4. Regular inspections: Regular inspections should be conducted to monitor the condition of steel props during use. This includes checking for signs of wear and tear, such as rust or corrosion, and immediately replacing or repairing any damaged or compromised props. 5. Proper storage and transportation: Steel props should be stored in a dry and secure location to prevent damage and deterioration. During transportation, they should be adequately secured to prevent movement or damage that could affect their structural integrity. 6. Training and supervision: Workers responsible for using steel props should receive proper training on their correct usage and safety precautions. They should also be supervised during installation and use to ensure compliance with all safety measures. By following these safety precautions, the risk of accidents or structural failures while using steel props can be minimized, creating a safe working environment for all workers involved.

- Q: Can steel props be used in the construction of oil and gas facilities?

- Steel props, known as adjustable steel props or steel shoring props, have extensive application in the construction of oil and gas facilities. They serve the purpose of supporting temporary structures and providing stability during construction projects. These props are designed specifically to withstand heavy loads, constructed from high-quality steel to ensure durability and strength. During the construction of oil and gas facilities, steel props find multiple uses. They are employed to offer temporary support during the installation of equipment like pipelines, tanks, or platforms. Furthermore, these props contribute to stabilizing structures during maintenance or repair work, prioritizing worker safety and preventing potential structural damage. The adaptability of steel props makes them ideal for oil and gas facility construction. Their adjustable nature allows for easy customization to meet specific requirements. They can be extended or retracted as needed, ensuring flexibility in different construction scenarios. In addition to their flexibility, steel props offer various advantages, including quick installation and dismantling, cost-effectiveness, and reusability. These qualities make them the preferred choice in the construction industry, particularly for oil and gas facilities, where time, budget, and efficiency are critical factors. However, it is crucial to mention that the use of steel props in oil and gas facilities must adhere to safety regulations and industry standards. A thorough engineering analysis and design considerations should be undertaken to ensure the proper and safe utilization of props in these sensitive environments.

- Q: Can steel props be used in the construction of bridges or viaducts?

- Absolutely, bridges or viaducts can certainly utilize steel props in their construction. Steel props, also referred to as adjustable steel props or steel acrow props, are frequently employed in construction endeavors to provide support for formwork, scaffolding, or temporary structures. During the construction of bridges and viaducts, robust and stable support systems are crucial to ensure safety and structural integrity. Steel props are an ideal option for this purpose due to their ability to bear heavy loads and their adjustability. These props consist of an inner tube, an outer tube, a base plate, and a threaded rod that can be extended or retracted to achieve the desired height and support. Steel props offer numerous advantages for bridge and viaduct construction. Firstly, their composition of steel, a strong and durable material, enables them to withstand substantial loads, making them well-suited for supporting the weight of bridge or viaduct components during construction. Additionally, steel props can be easily adjusted to accommodate varying heights and angles, providing flexibility in construction projects where different sections of the bridge or viaduct may require different levels of support. Moreover, steel props are relatively lightweight and portable, facilitating easy transportation and on-site installation. They can be swiftly assembled and disassembled, contributing to efficient construction processes. Additionally, the reusability of steel props in multiple projects helps reduce costs and minimizes environmental impact. In conclusion, the utilization of steel props in the construction of bridges or viaducts is indeed feasible. Their strength, adjustability, portability, and cost-effectiveness render them a suitable choice for providing temporary support during the construction of these structures.

Send your message to us

Scaffolding System Ringlock Scaffold Vertical

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords