PPGI Color Coated Sheet/Color Coated Steel Coil/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Application of Color Coated Steel Coil:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

2.Features of Color Coated Steel Coil:

With excellent cold-rolling steel strips as a base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

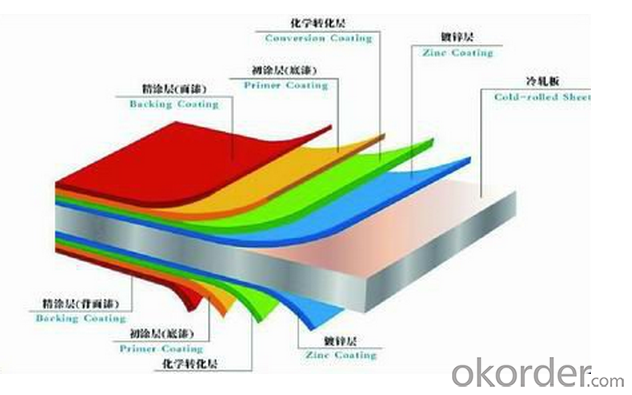

3.Details of Color Coated Steel Coil:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4.Color Coated Steel Coil Image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes, including shearing, slitting, and laser cutting.

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings by being fed through a machine that cuts and shapes the coil into individual rings. These rings can then be further processed and manipulated to create a wide range of steel products, such as bearings, pipe fittings, or automotive components.

- Q: What are the common applications of hot-dip galvanized steel coils?

- Hot-dip galvanized steel coils have a wide range of common applications, including roofing and construction materials, automotive parts, electrical appliances, and agricultural equipment. The galvanization process provides excellent corrosion resistance, making these coils ideal for outdoor structures and applications exposed to harsh environments.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- Soldering to steel is difficult. An electric iron may be enough depends on power. The steel must be clean. An abrasive like fine steel wool,fine sandpaper or even a rubber pencil eraser will work. Next an acid flux for the solder. Most electronic solder flux is not active enough for steel. Plumbers solder usually is. Plumbers solder is Lead free and has a slightly higher melting temp.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications including manufacturing aircraft components, structural supports, and engine parts. The coils are typically processed and shaped into specific forms such as sheets or plates, which are then used to construct critical components of aircrafts, ensuring strength, durability, and performance.

- Q: So what's harder gold or steel

- Steel Gold is a soft metal, that's why people bite it to make sure it is real.

- Q: How do steel coils contribute to the energy sector?

- Steel coils contribute to the energy sector in various ways. Firstly, steel coils are used in the manufacturing of equipment and infrastructure that is essential for energy production and distribution. For example, they are used in the construction of power plants, transmission towers, and pipelines. These structures require strong and durable materials, and steel coils provide the necessary strength and reliability. Moreover, steel coils play a crucial role in the renewable energy sector. They are used in the production of wind turbines and solar panels. Wind turbines require steel coils for their towers, while solar panels use steel frames to provide support and durability. As the demand for renewable energy sources continues to grow, the use of steel coils in this sector is expected to increase as well. Furthermore, steel coils are used in the production of electrical transformers. Transformers are vital components in the energy sector, as they facilitate the transmission and distribution of electricity. Steel coils are used to create the core of the transformer, which is responsible for the efficient transfer of electrical energy. The quality and reliability of the steel coils used in transformers are essential to ensure the smooth functioning of the electrical grid. In addition to their direct applications, steel coils also contribute to the energy sector indirectly. Steel is a recyclable material, and the recycling process consumes less energy compared to the production of new steel. By using recycled steel coils, the energy sector can reduce its carbon footprint and contribute to a more sustainable and environmentally friendly energy production process. Overall, steel coils are a vital component in the energy sector. They are used in the manufacturing of equipment and infrastructure, including power plants, transmission towers, wind turbines, solar panels, and electrical transformers. Additionally, the recyclability of steel contributes to the sustainability of the energy sector.

- Q: What is the average size of a steel coil?

- The average size of a steel coil can vary depending on the specific application and industry. However, in general, steel coils typically have a width ranging from 600mm to 2000mm and a weight between 2 to 25 metric tons.

- Q: How are steel coils used in the manufacturing of steering columns?

- Steel coils are used in the manufacturing of steering columns as they provide the necessary strength and durability required for this crucial automobile component. The steel coils are formed into specific shapes and sizes, which are then used to create the structural framework of the steering column. This ensures that the steering column can withstand the forces and stresses encountered during vehicle operation, allowing for safe and reliable steering control.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- Hardening is the preliminary process. The fully hardened state may be far too brittle for practical use. The tempering process is tailored to reduce the actual hardness, to introduce more flexible alloys. The tempering method employed may be done at relatively low temperatures, but some alloys require prolonged soaking at elevated temperatures. Some may be cooled in air, but others may require quenching to end the process.

Send your message to us

PPGI Color Coated Sheet/Color Coated Steel Coil/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords