color coated sheets and coils of bright color/ppgi coils/cold steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

color coated sheets and coils of bright color/ppgi coils/cold steel coils

1. Application of color coated sheets and coils of bright color/ppgi coils/cold steel coils

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

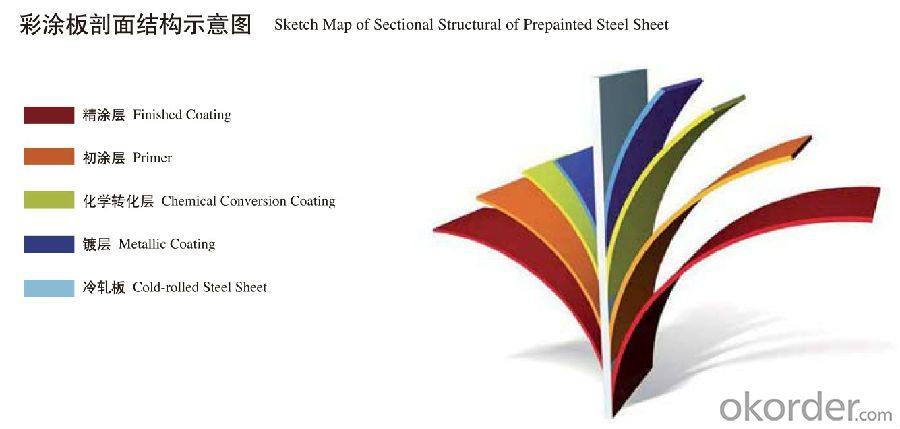

2.Features color coated sheets and coils of bright color/ppgi coils/cold steel coils

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of color coated sheets and coils of bright color/ppgi coils/cold steel coils:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

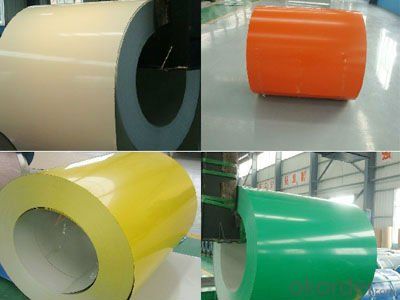

4.color coated sheets and coils of bright color/ppgi coils/cold steel coils image:

APPLICATION:

PROUDUCTION LINE:

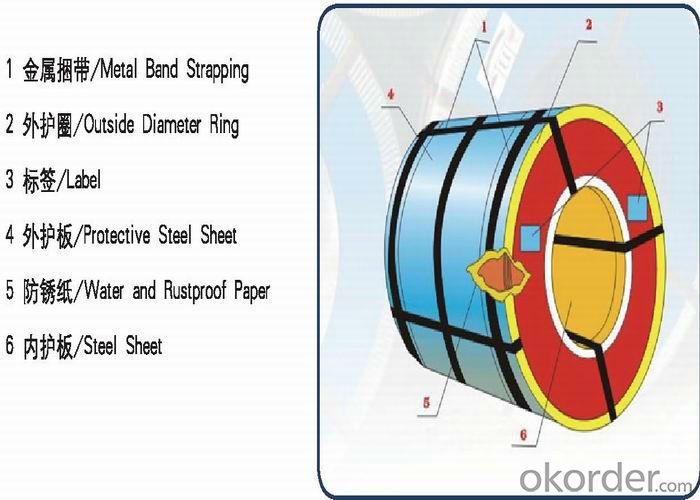

PACKING:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How is the thickness of a steel coil measured?

- The thickness of a steel coil is typically measured using a tool called a thickness gauge, which is capable of accurately determining the thickness of the steel through direct contact.

- Q: What are the common challenges in steel coil manufacturing?

- There are several common challenges in steel coil manufacturing that manufacturers often face. One of the major challenges is maintaining consistent quality throughout the manufacturing process. Steel coils need to meet specific specifications and standards, and any deviation from these can lead to product defects or rejections. This requires careful monitoring and quality control measures at each stage of the manufacturing process. Another challenge is ensuring efficient production and minimizing downtime. Steel coil manufacturing involves several complex processes, including cutting, forming, welding, and finishing. Any issues or delays in these processes can result in production bottlenecks, which can impact the overall efficiency and productivity of the manufacturing facility. Additionally, handling and storage of steel coils can pose challenges. Steel coils are heavy and can be difficult to handle, requiring specialized equipment and proper training for workers. Moreover, proper storage conditions need to be maintained to prevent damage from moisture, corrosion, or other environmental factors. Maintaining a safe working environment is also a challenge in steel coil manufacturing. The equipment and machinery used in the manufacturing process can be hazardous if not operated and maintained properly. Ensuring the safety of workers and implementing appropriate safety protocols is crucial to prevent accidents and injuries. Lastly, fluctuating raw material costs and market demands can present challenges for steel coil manufacturers. The cost of raw materials, such as iron ore and scrap metal, can significantly impact the profitability of the manufacturing process. Additionally, market demands for specific types of steel coils may change, requiring manufacturers to adapt and adjust their production accordingly. In conclusion, common challenges in steel coil manufacturing include maintaining consistent quality, achieving efficient production, handling and storage issues, ensuring a safe working environment, and dealing with fluctuating raw material costs and market demands. Overcoming these challenges requires careful planning, continuous improvement, and effective management of resources and processes.

- Q: How are steel coils inspected for thickness and width accuracy?

- Steel coils are inspected for thickness and width accuracy using various methods such as ultrasonic testing, laser measurement systems, and manual measurements. Ultrasonic testing involves the use of sound waves to measure the thickness of the coil, while laser measurement systems provide precise width measurements. Additionally, manual measurements are also conducted by trained inspectors who use specialized tools to ensure the accuracy of thickness and width dimensions.

- Q: What is the process of pickling and oiling steel coils?

- To ensure the quality and protection of steel coils, a series of steps are undertaken in the process of pickling and oiling. The first step involves pickling, wherein impurities and scale are removed from the surface of the steel coil. This is achieved by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which effectively dissolves any oxides, rust, or contaminants present on the surface. This step is critical as it readies the steel for further processing and safeguards against potential defects or corrosion. Following pickling, the steel coils are rinsed with water to eliminate any residual acid and then dried. Once they are clean and dry, a layer of oil is applied to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating acts as a barrier, preventing rusting or oxidation before the steel undergoes further processing or is utilized in various applications. The oiling process can be executed through various methods. One common approach is to apply the oil using a roller or brush, ensuring an even coating across the entire surface of the coil. Alternatively, the coils can be passed through a bath or spray chamber where the oil is administered. The choice of oil depends on the specific requirements of the steel and its intended use, with options ranging from mineral oil and synthetic oils to specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is crucial to handle the coils with care to avoid damaging the oil coating and compromising the corrosion protection it provides. Overall, the pickling and oiling of steel coils are indispensable steps in the steel manufacturing process. They ensure the quality, cleanliness, and protection of the steel, thereby prolonging its lifespan and enhancing its performance in various applications.

- Q: What are the different thickness tolerances for steel coils?

- The specific requirements and industry standards can cause the thickness tolerances for steel coils to vary. There are several common thickness tolerances for steel coils: - The standard tolerance ranges from ±0.005 inches to ±0.010 inches. This means that the actual thickness of the steel coil can deviate within this range from the specified thickness. - Stricter tolerances, known as tighter tolerances, may be necessary in certain cases, particularly for critical applications or industries. These tighter tolerances can range from ±0.002 inches to ±0.005 inches, ensuring more precise thickness control for the steel coils. - Custom thickness tolerances can be defined to meet the specific needs of a project or customer. These custom tolerances can be looser or tighter than the standard or tighter tolerances, depending on the application and desired precision level. It is important to consider that different industries and applications may have their own unique tolerance requirements. For example, industries such as automotive or aerospace may demand tighter tolerances due to the critical nature of their applications, while other industries may accept looser tolerances. Additionally, the specific type of steel being used can also affect the acceptable thickness tolerances. Therefore, consulting the relevant industry standards and specifications is crucial in determining the appropriate thickness tolerances for steel coils in a particular application.

- Q: How are steel coils used in the production of electrical equipment?

- Steel coils are used in the production of electrical equipment as they serve as the core component for transformers. The coils are made from high-quality steel to ensure efficient electrical conductivity and magnetic properties. They are wound around a core to create an electromagnetic field that helps in the transformation of voltage levels, enabling the smooth transmission and distribution of electricity.

- Q: In the warehouse management system of steel coil

- Warehouse is an important component of enterprise material supply system. It is also the tache of enterprise material circulation and storage, and it also undertakes many functions of material management. Its main tasks are to keep the stock well, to be accurate, to be of good quality, to ensure safety, to prompt the people, to produce, to be considerate, to reduce costs, and to speed up capital turnover.

- Q: What are the different surface treatments for steel coils?

- Some common surface treatments for steel coils include hot-dip galvanizing, electro-galvanizing, zinc coating, paint coating, and powder coating. These treatments help to enhance the corrosion resistance and aesthetic appearance of the steel coils, making them suitable for various applications in industries such as construction, automotive, and manufacturing.

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- *Alloy steel is not same as stainless steel. An alloy steel is not the perfect spring steel. Since you are doing the project, please understand the carbon steel,alloy steel and super alloys. Alloy steel is steel alloyed with a variety of elements in amounts of between 1 and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. Stainless steel is a type of high alloy steel. *As far as spring material is concern , spring steel or music wire is best suited. Spring steel is a low alloy, medium carbon steel or high carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant bending or twisting. Silicon is the key component to most spring steel alloys. An example of a spring steel used for cars would be AISI 9255 (DIN and UNI: 55Si7, AFNOR 55S7), containing 1.50%-1.80% silicon, 0.70%-1.00% manganese and 0.52%-0.60% carbon. Most spring steels (as used in cars) are hardened and tempered to about 45 Rockwell C. Since sufficient links were given earlier but I like you to go through spring steel as it is your subject matter. I have done the project on The design of a helical compression spring selected material was ASTM A228 (0.80–0.95% carbon).

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

Send your message to us

color coated sheets and coils of bright color/ppgi coils/cold steel coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords