All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil packaging and banding optimized for safe transportation in the aerospace sector?

Coil packaging and banding in the aerospace sector is optimized for safe transportation through various measures. Firstly, specialized packaging materials are used to protect the coil from external elements, such as moisture, dust, and temperature fluctuations, which could potentially damage the coil during transit. Additionally, banding techniques are employed to securely hold the coil in place, preventing any movement or shifting that could lead to damage. These bands are carefully applied to avoid causing any stress or pressure points on the coil. The packaging and banding processes are designed to ensure that the coil remains intact and well-protected throughout its journey, guaranteeing safe transportation in the aerospace sector.

What is the impact of coil edge quality on the performance and safety of electrical transmission and distribution equipment?

The impact of coil edge quality on the performance and safety of electrical transmission and distribution equipment is significant. Poor coil edge quality can lead to various issues such as increased electrical resistance, insulation breakdown, and mechanical stress. These factors can result in power losses, decreased efficiency, and potential hazards like short circuits, overheating, or fire. On the other hand, high-quality coil edges ensure better electrical conductivity, reduced energy losses, enhanced insulation integrity, and improved overall equipment reliability and safety. Therefore, maintaining good coil edge quality is crucial for optimal performance and safe operation of electrical transmission and distribution equipment.

How does coil cleanliness affect the quality of downstream processes?

Coil cleanliness directly affects the quality of downstream processes by ensuring optimal heat transfer and preventing system inefficiencies. When coils are clean, they can effectively remove heat from the process fluid, maintaining desired temperatures and preventing overheating. This leads to improved productivity, energy efficiency, and overall performance of downstream processes. On the other hand, dirty coils restrict heat transfer, reduce system capacity, and increase energy consumption, resulting in compromised process quality and potential equipment failures. Therefore, maintaining coil cleanliness is crucial for maintaining the quality and effectiveness of downstream processes.

Wholesale Steel Coils from supplier in Guinea

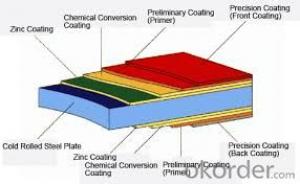

Our team of experts is highly knowledgeable in the steel industry and can assist you in making informed decisions regarding your steel coil requirements. We offer a wide range of steel coil products, including hot-rolled coils, cold-rolled coils, galvanized coils, and prepainted coils, among others.

In addition to supplying high-quality steel coils, we also provide comprehensive services to ensure a seamless procurement process. Our sales team is dedicated to understanding your specific needs and providing tailored solutions. We offer competitive pricing and timely delivery to meet your project deadlines.

Moreover, we provide detailed quotations that are transparent and easy to understand, helping you make informed decisions based on your budget and requirements. Our technical support team is available to assist you with any inquiries or issues you may have, ensuring that you have all the necessary information to make the right choice.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to handle all your steel coil procurement needs. Our experience in the Guinea market allows us to offer valuable insights into local regulations, market trends, and best practices. We understand the unique challenges and requirements of operating in Guinea and can provide you with the necessary support to ensure the success of your projects.

Whether you are involved in construction, manufacturing, or any other industry that requires steel coils, we are here to assist you. Contact us today for all your steel coil needs in Guinea, and let us be your trusted partner in procurement.

In addition to supplying high-quality steel coils, we also provide comprehensive services to ensure a seamless procurement process. Our sales team is dedicated to understanding your specific needs and providing tailored solutions. We offer competitive pricing and timely delivery to meet your project deadlines.

Moreover, we provide detailed quotations that are transparent and easy to understand, helping you make informed decisions based on your budget and requirements. Our technical support team is available to assist you with any inquiries or issues you may have, ensuring that you have all the necessary information to make the right choice.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to handle all your steel coil procurement needs. Our experience in the Guinea market allows us to offer valuable insights into local regulations, market trends, and best practices. We understand the unique challenges and requirements of operating in Guinea and can provide you with the necessary support to ensure the success of your projects.

Whether you are involved in construction, manufacturing, or any other industry that requires steel coils, we are here to assist you. Contact us today for all your steel coil needs in Guinea, and let us be your trusted partner in procurement.