All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

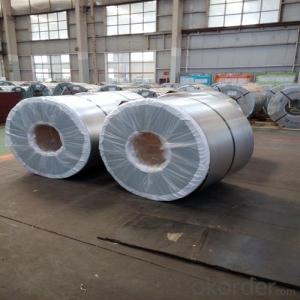

How is electrolytic tinplate coil stored and transported?

Electrolytic tinplate coil is typically stored and transported in a controlled environment to prevent any damage or contamination. It is commonly stored in warehouses or storage facilities that maintain a stable temperature and humidity levels. The coils are usually stacked on pallets, with proper support and padding in between to prevent any scratching or denting. When being transported, they are carefully loaded onto trucks or containers, ensuring they are securely fastened to prevent any movement or shifting during transit. Additionally, the coils may be covered or wrapped with protective materials to safeguard them from dust, moisture, or other potential hazards.

How does electrolytic tinplate coil perform in terms of chemical resistance?

Electrolytic tinplate coil exhibits excellent chemical resistance due to the presence of a tin layer on the surface. The tin layer acts as a protective barrier, preventing corrosion and degradation when exposed to various chemicals. This allows the tinplate coil to withstand a wide range of acids, alkalis, and other corrosive substances, making it a reliable choice for applications requiring chemical resistance.

How does the surface roughness of electrolytic tinplate coil affect its adhesion properties?

The surface roughness of electrolytic tinplate coil has a direct impact on its adhesion properties. A rougher surface provides a larger contact area between the tinplate and the adhesive, leading to stronger adhesion. Additionally, the roughness can improve the mechanical interlocking between the tinplate and the adhesive, enhancing the overall adhesion strength. Therefore, a higher surface roughness generally results in better adhesion properties for electrolytic tinplate coil.

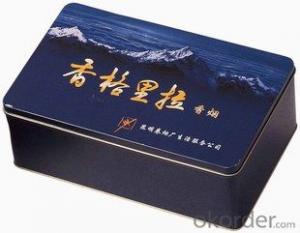

Can electrolytic tinplate coil be used in the production of metal lug caps?

Yes, electrolytic tinplate coil can be used in the production of metal lug caps.

What are the disadvantages of using electrolytic tinplate coil?

One of the main disadvantages of using electrolytic tinplate coil is its relatively high cost compared to other types of packaging materials. Additionally, electrolytic tinplate coil is susceptible to corrosion, especially in acidic or high-humidity environments. It is also less flexible than other materials, making it less suitable for certain applications. Moreover, the tin coating on the coil may degrade over time, leading to potential contamination of the packaged product.

Wholesale Electrolytic Tinplate Coil from supplier in Guinea

Our team of experts is dedicated to assisting you throughout the entire procurement process, from product selection to delivery. We understand the specific requirements of the Guinea market and can provide tailored solutions to meet your needs.

Whether you are looking for standard tinplate coils or customized options, we have a wide range of products to choose from. Our Electrolytic Tinplate Coils are manufactured to the highest quality standards, ensuring reliable performance and durability.

In addition to our product offerings, we also provide comprehensive technical support services. Our team of engineers is available to answer any questions you may have and provide guidance on product selection and usage. We are committed to ensuring that you have the necessary information and support to make informed decisions for your projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver high-quality products and services. Our strong global network enables us to source products from reliable manufacturers and ensure timely delivery to our customers in Guinea.

Contact us today to discuss your Electrolytic Tinplate Coil requirements and discover how we can support your projects in Guinea.

Whether you are looking for standard tinplate coils or customized options, we have a wide range of products to choose from. Our Electrolytic Tinplate Coils are manufactured to the highest quality standards, ensuring reliable performance and durability.

In addition to our product offerings, we also provide comprehensive technical support services. Our team of engineers is available to answer any questions you may have and provide guidance on product selection and usage. We are committed to ensuring that you have the necessary information and support to make informed decisions for your projects.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver high-quality products and services. Our strong global network enables us to source products from reliable manufacturers and ensure timely delivery to our customers in Guinea.

Contact us today to discuss your Electrolytic Tinplate Coil requirements and discover how we can support your projects in Guinea.