All Categories

- - Steel Wire Rod

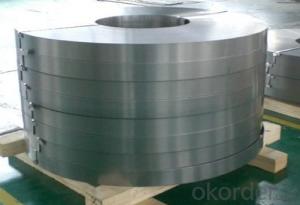

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What challenges are faced in producing ultra-high-strength steel coils for aerospace applications?

Producing ultra-high-strength steel coils for aerospace applications faces several challenges. Firstly, achieving the desired strength requires precise control over the composition and heat treatment processes, which can be complex and costly. Additionally, maintaining the required mechanical properties throughout the manufacturing process is crucial, as any deviation can compromise the structural integrity of the coils. Furthermore, ensuring consistent quality and uniformity across large-scale production can be demanding, given the stringent specifications and rigorous testing requirements for aerospace applications. Lastly, meeting the evolving industry standards and staying ahead of the competition in terms of strength-to-weight ratio and cost-effectiveness poses an ongoing challenge for manufacturers in this field.

What role do coil packaging and banding play in the safe transportation of steel coils?

Coil packaging and banding play a crucial role in ensuring the safe transportation of steel coils. They provide a secure and stable packaging solution that prevents the coils from shifting or falling during transit. The packaging materials, such as shrink wrap or wooden crates, protect the coils from external elements like moisture, dust, and corrosion, preserving their quality and integrity. Additionally, banding, which involves securing the coils with steel or plastic bands, adds an extra layer of stability and prevents any potential movement or damage. Overall, coil packaging and banding significantly reduce the risk of accidents, damage, and injuries during transportation, ensuring that the steel coils reach their destination safely.

What is the significance of coil edge straightness in the manufacturing of industrial equipment?

The significance of coil edge straightness in the manufacturing of industrial equipment lies in ensuring proper alignment and fit of the coils. Straight edges allow for optimal stacking and welding of coils, ensuring structural integrity and efficient heat transfer. It also aids in preventing coil damage during handling and installation, leading to improved performance and longevity of the equipment.

What are the main properties of steel coils?

The main properties of steel coils include high strength, durability, corrosion resistance, and the ability to be formed into various shapes and sizes. They are also known for their excellent thermal conductivity and electrical conductivity.

Wholesale Steel Coils from supplier in Bulgaria

With our professional sales team, we can provide you with personalized quotations and recommendations based on your specific requirements. Our technical support team is always available to assist you with any questions or concerns you may have regarding the use and installation of our Steel Coils products.

As a leading supplier, we understand the importance of timely delivery and reliable logistics. We have established strong partnerships with reputable transportation companies to ensure that your orders are delivered to your desired location in a timely manner.

In addition to our product offerings, we also provide value-added services such as customization and fabrication. Whether you need specific dimensions, coatings, or finishes, we can work with you to create tailored solutions that meet your exact specifications.

Our commitment to customer satisfaction is unwavering, and we strive to exceed your expectations in every aspect of our business. We are dedicated to building long-term partnerships with our clients, and we believe that our expertise, reliability, and customer-centric approach set us apart from other suppliers in the market.

When you choose us as your Steel Coils supplier in Bulgaria, you can trust that you are working with a reputable company backed by the support and resources of CNBM. We look forward to the opportunity to serve you and contribute to the success of your projects.

As a leading supplier, we understand the importance of timely delivery and reliable logistics. We have established strong partnerships with reputable transportation companies to ensure that your orders are delivered to your desired location in a timely manner.

In addition to our product offerings, we also provide value-added services such as customization and fabrication. Whether you need specific dimensions, coatings, or finishes, we can work with you to create tailored solutions that meet your exact specifications.

Our commitment to customer satisfaction is unwavering, and we strive to exceed your expectations in every aspect of our business. We are dedicated to building long-term partnerships with our clients, and we believe that our expertise, reliability, and customer-centric approach set us apart from other suppliers in the market.

When you choose us as your Steel Coils supplier in Bulgaria, you can trust that you are working with a reputable company backed by the support and resources of CNBM. We look forward to the opportunity to serve you and contribute to the success of your projects.