Paper Grade Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production method Of Paper Grade Indirect Zinc Oxide:

With the rapid development of industrial and agricultural economy, the demand for special paper has been diversified, and it has put forward higher requirements. Zinc oxide in the paper industry is mainly used in anti-water, anti-bacterial, anti-static, anti-aging and flavoring, fire-retardant, color paper and other functions of the development of nano-Zinc oxide gradually be applied as a paper additive.

Application Of Paper Grade Indirect Zinc Oxide:

The zinc oxide for papermaking, it can be used in the zinc oxide printing plate, zinc oxide paper production.

1. It is small granule, easy to disperse. It can make printing plate homogenized, fine and smooth

2. Zinc oxide is luster pure white and tinting strength. It can increase the paper white degree, also has advantageous for the colored paper coloration

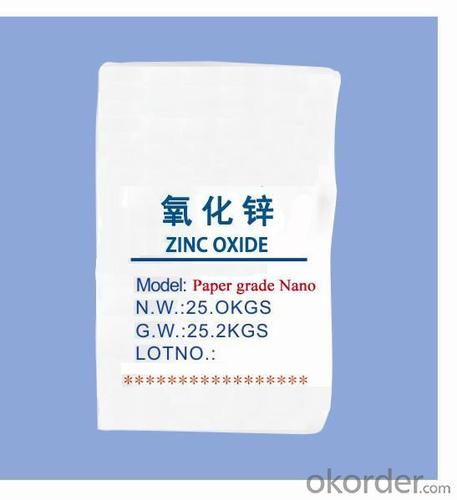

Packing and storage Of Paper Grade Indirect Zinc Oxide:

This product is packed with plastic-lined and plastic-coated woven bags, 25kg per bag.

This product should be keep from breakage, moisture, pollution and contact with acid.

Product quality standards: GB/T 3185-92

ITEM | Quality | ||||

101 | 102 | 103 | 104 | 105 | |

Zinc oxide(counted by dried substances )/%≥ | 99.7 | 99.5 | 99.4 | 98 | 96 |

Metal ( Zn ) /%≤ | None | None | None | None | None |

Lead oxide( Pb)/ %≤ | 0.037 | 0.05 | 0.14 | 0.15 | 0.2 |

Hydrochloric indissoluble substance/ %≤ | 0.006 | 0.008 | 0.05 | 0.1 | 0.2 |

Burning decrement /%≤ | 0.2 | 0.2 | 0.2 | 0.3 | 0.4 |

Water dissoluble/ %≤ | 0.10 | 0.10 | 0.15 | 0.3 | 0.5 |

105℃volatile substances/ %≤ | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 |

Specific surface area(㎡/g)≥ | 60 | 50 | 40 | 30 | 30 |

Grain size (um) | 4–20 | 4﹣40 | 4﹣40 | 4-50 | 4–50 |

- Q: How is the paint made? What is the material?

- Paint is made of iron oxide or resin and other raw materials used to decorate and protect the goods of the paint. The origin of the paint is inconclusive. In 1500 BC, in French and Spanish caves, paint was used for painting and decoration. BC 6000 years, China has been using inorganic compounds and organic pigments mixed roasting to improve the paint. In 1500 BC, the Egyptians made use of dyed search materials such as indigo and madder to make blue and red pigments, but the paint was still imperfect.

- Q: Paint on the girls what harm

- Hurt the liver, often smell the smell of paint will hurt the liver, will be hair loss.

- Q: How do you start painting with oil paint, the techniques and brush strokes

- I paint with oils one of two ways. The first is when I want a smooth painting, I paint like I was painting with acrylics. Lots of blending and smoothing. The second, when I want a lot of texture, I paint with a palette knife.

- Q: What is the polymerization mechanism by which the low molecular weight monomer is converted into a polymer

- This can find their own information

- Q: How do you remove the paint?

- Newly stained red ink stains can be washed first, and then soaked in warm soap, until the color stains removed, and then washed with fresh water. Contaminated for a long time the red ink stains, first washed with water, then wipe with 10% alcohol solution to remove.

- Q: I am a beginner at painting so how do I paint like the pros? First and second coat?thanks : - ]

- First of all, a lot of pros out there can barely paint. Second - what exactly are you looking to emulate? If you want to paint abstract work like a pro, paint a lot and learn about your colors, how they interact, how quickly the paint dries, etc. If you want to paint realistically, paint a lot and polish your drawing. In my experience, folks who can draw well can also paint well. Very rarely will you see a person who can paint better than they can draw. If you want to paint ANYTHING, paint it. You need to practice. It will also benefit you to look at books on painting, and perhaps take a painting class. There is no need to go to art school, unless you truly want to go that route. The benefit to taking classes (at a community college for example) is to have someone explain - in person - how the different painting materials work together (what one medium vs. another will do, different ways to apply paint with your brush, what colors may look better together/mixed, etc). My advice is to invest in some nice brushes (your art store owner or salesperson can guide you) and invest in some nice paints (cheap paints are awful, but super nice paints are unnecessary - start somewhere in the middle). Use less expensive canvas and/or painting surfaces for your paintings. You can get creative and start buying expensive canvas or stretching your own canvas later on down the road. Enjoy painting!

- Q: Brush latex paint or stickers good wallpaper?

- environmental aspects, the latex paint and wallpaper in the end which is more environmentally friendly? Paint is certainly VOC and free formaldehyde, but the general manufacturers of brand-name paint can control the harmful substances at a relatively low level, and paint dry These harmful substances will be completely volatile, and then there will be no environmental issues. So that the paint is in the short term there will be a relatively low degree of minor pollution.

- Q: When the oil paint is not enough when you can mix some gouache paint use?

- Oil paints are made from pigment powder and oil. The market for the sale of mostly tube, can also be made. The basic ingredients of oil paints and other paint pigments, such as colorants, physical pigments, vehicle and some accessories such as plastic agents, stabilizers, slow dryers or driers and other components. Ancient master paint powder used mostly from the soil and minerals. The other part comes from plants or animals.

- Q: Polymer batteries and 18650 batteries in the end which is more secure?

- 18650 batteries exist the risk of explosion, and the polymer battery is the worst case of fire. I used the Ithink mobile power, the polymer was very good.

- Q: The use of propylene dyes

- Propylene dyes can be formulated with water. It is a new type of paint pigment prepared by mixing a chemical synthetic latex (including acrylate, methacrylate, acrylic acid, methacrylic acid, and thickener, filler, etc.) with color particles. It can be washed with water Dilute, facilitate cleaning.

1. Manufacturer Overview

| Location | Chongqing, China |

| Year Established | 1958 |

| Annual Output Value | Above US$10 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Central America; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Luzhou Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 120,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Paper Grade Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords