Papaer Grade NANO-Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production method Of Paper Grade NANO-Zinc Oxide:

With the rapid development of industrial and agricultural economy, the demand for special paper has been diversified, and it has put forward higher requirements. Zinc oxide in the paper industry is mainly used in anti-water, anti-bacterial, anti-static, anti-aging and flavoring, fire-retardant, color paper and other functions of the development of nano-Zinc oxide gradually be applied as a paper additive.

Application Of Paper Grade NANO-Zinc Oxide:

The zinc oxide for papermaking, it can be used in the zinc oxide printing plate, zinc oxide paper production.

1. It is small granule, easy to disperse. It can make printing plate homogenized, fine and smooth

2. Zinc oxide is luster pure white and tinting strength. It can increase the paper white degree, also has advantageous for the colored paper coloration

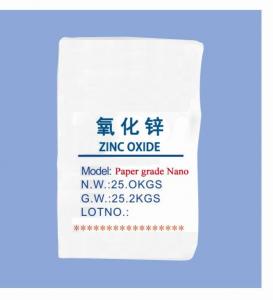

Packing and storage:

This product is packed with plastic-lined and plastic-coated woven bags, 25kg per bag. This product should be keep from breakage, moisture, pollution and contact with acid.

Product quality standards: GB/T 3185-92

ITEM | Quality | ||

131 | 132 | 133 | |

ZnO/% ≥ | 99.0 | 97.0 | 95.0 |

Grain nm≤ | 20 | 57 | 100 |

XRD /nm≤ | 20 | 52 | 100 |

Surface proportion (㎡/g)≥ | 60 | 62 | 65 |

Join index≤ | 50 | 60 | 100 |

Lead oxide( Pb )/%≤ | 0.0005 | 0.0005 | 0.0005 |

Manganese Oxide /% ≤ | 0.0001 | 0.0001 | 0.0001 |

Cupric oxide(Cu)/%≤ | 0.0001 | 0.0001 | 0.0001 |

Cd/%≤ | 0.0002 | - | - |

Hg/%≤ | 0.0001 | - | - |

As/%≤ | 0.0001 | - | - |

105℃volatile substances %≤ | 0.30 | 0.4 | 0.5 |

Water dissoluble % ≤ | 0.10 | 0.41 | 0.5 |

Hydrochloric acid insoluble %≤ | 0.02 | 0.02 | 0.02 |

Burning decrement %≤ | 2 | 2 | 2 |

- Q: What is the difference between thermal transfer ink and sublimation ink?

- Sublimation thermal transfer is the use of disperse dye sublimation characteristics, that is printed on the transfer paper in the dye reaches the transfer temperature, the dye began to evaporate, and constantly penetrate into the fabric gap until the transfer of paper on the dye used or tend to use Finished, transfer paper on the residual dyes less, indicating the transfer on the fabric on the more, that is, the higher the saturation, the more colorful pattern, the more realistic. This is the quality of sublimation transfer paper quality As a core element.Because the thermal sublimation is the process of dye diffusion to the fabric, so sublimation pattern transfer does not change the original texture of the material, printing parts breathable, comfortable, feel and feel good, while the heat transfer is another Of a method: cotton or cotton with a high amount of fabric itself does not absorb the color, if the use of sublimation printing cotton, it is easy to wash away. In order not to be washed out, to use a dedicated thermosetting transfer paper.When the mug, the surface of the mug has been coated with a coating to absorb the color, but the coating can not be painted on the clothes, So it can only be coated on the transfer paper, so the printer is actually the pigment printed on the thermal transfer paper with the naked eye can not see the top of the coating, and then under high temperature and pressure, the actual transfer on the fabric is the coating And pigment mixture, rather than a simple pigment, so after the transfer has a hard feel, printing part of the airtight, transfer paper quality is directly on the thickness of the glial layer, the worse the quality, the greater the thickness , If the printing pattern area is large, as a measure of personalized costumes and functional comfort and beauty will no longer exist.

- Q: Qilu paint and music pain which is good?

- What brand of these two ah? Never heard, if the election of paint that election Bauhinia net good enjoy the series of paint, quality guaranteed

- Q: What is the main difference between a one-component polyurethane and a polymer cement-based waterproof coating?

- One-component wet-curing polyurethane resin coating construction is simple, the substrate treatment requirements are not too strict, the surface of the construction material without clean water, construction ingredients do not strictly measured.

- Q: Paint wastewater treatment

- In the cathodic electrophoresis wastewater contains a large number of high molecular organic compounds, CODCr up to 20000mg / L, also contains a large number of electrophoretic slag, these substances in the water was a small suspended matter or negative charge colloidal. The appropriate cationic polyacrylamide (PAM) and polyaluminium chloride (PAC) were added as coagulants, and the pollutants in the wastewater were quickly removed by the adsorption bridging action of the flocculant. Electrophoretic waste liquid in the pretreatment requires pH between 11 ~ 12, a better precipitation effect. The effluent CODCr after the reaction was around 2000 mg / L.

- Q: or just making normal paint

- buy it, then you mix it up to get the colors right, and paint, really simple if you're a begginer, also you can get various effects, by adding water,etc Main article: Acrylic painting techniques Acrylic artist paints may be thinned with water and used as washes in the manner of watercolor paints, but the washes are not re-hydratable once dry. For this reason, acrylics do not lend themselves to color lifting techniques as do gum arabic based watercolor paints. Acrylic paints can be used in high gloss or matte finishes. As with oils, pigment amounts and particle size can alter the paint sheen. Likewise, matting agents can be added to dull the finish. Topcoats or varnishes may also be applied to alter sheen. When dry, acrylic paint is generally non-removable. Water or mild solvents do not re-solubilize it, although isopropyl alcohol can lift some fresh paint films off. Toluene and acetone can remove paint films, but they do not lift paint stains very well and are not selective. The use of a solvent to remove paint will result in removal of all of the paint layers, acrylic gesso, etc. Only a proper, artist-grade acrylic gesso should be used to prime canvas in preparation for painting with acrylic. It is important to avoid adding non-stable or non-archival elements to the gesso upon application. Acrylic will not form a stable paint film if it has been thinned with more than 30% water content. However, the viscosity of acrylic can successfully be reduced by using suitable extenders that maintain the integrity of the paint film. There are retarders to prolong drying and workability time and a flow release to increase color blending ability.

- Q: What is the difference between paint and putty powder?

- Putty special wall foundation basis better in the construction to do paint is paint and the like

- Q: I'm looking to paint the mid-sole on some Jordans, and I can't find Angelus paint at the stores, so are there any alternatives??

- Angelus paint is just acrylic paint. You can go to a craft store near you and buy small jars of artist's acrylic paint. And use them, they come in hundreds of different colors and are probably much cheaper in price. Angelus calls it leather paint, but all they are, are regular acrylic paints.

- Q: I heard that textile dyes can not cover, that can also be black in these dark clothes on DIY?

- You can use paint paste on it.

- Q: 2g yellow is a pigment or a dye?

- Nature: dark yellow powder. Soluble in water was yellow, slightly soluble in ethanol, chloroform and lysosomal, insoluble in other organic solvents. In concentrated sulfuric acid was red and yellow, diluted yellow solution and precipitation; in concentrated nitric acid was yellow solution. Its aqueous solution, concentrated hydrochloric acid or concentrated sodium hydroxide solution, are yellow. Dyeing, the case of copper ion color slightly darker, the case of iron color is darker. Good discharge.

1. Manufacturer Overview

| Location | Hebei ,China |

| Year Established | 1958 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41%-50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Papaer Grade NANO-Zinc Oxide

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 6000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches