Magnesium Oxide Cement Recipe

Magnesium Oxide Cement Recipe Related Searches

Magnesium Production Process Magnesium Sheet Oil Well Cement Composition Magnesium Metal Powder Msds Sheet For Magnesium Concrete Admixture Formulation Magnesium Anode Water Heater Cement Block Making Chicken Aluminum Foil Recipe Magnesium Alloy Magnesium China Foam Concrete Admixture Magnesium Foils Magnesium Anode Rod For Water Heater Aluminum Foil Recipes Magnesium Metal Magnesium Pellets Us Magnesium Mn Magnesium Etching Magnesium Plate Magnesium Silicate Solubility Magnesium Welding Wire Reynolds Aluminum Foil Recipes Pidgeon Process Magnesium Production Magnesium Turning Aluminum Foil Dinner Recipes Pidgeon Process Magnesium Vma Concrete Admixture Grill Aluminum Foil Recipes Forming ConcreteMagnesium Oxide Cement Recipe Supplier & Manufacturer from China

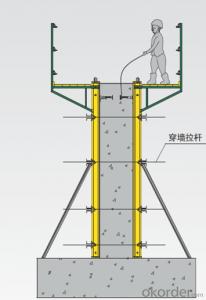

Magnesium Oxide Cement Recipe is a unique and versatile building material that consists of magnesium oxide powder and water. When combined, these two components create a hard, durable, and lightweight product that is highly resistant to fire, water, and mold. This eco-friendly and sustainable material is known for its excellent insulating properties and is widely used in various construction and renovation projects.The application and usage scenarios for Magnesium Oxide Cement Recipe are vast, making it an ideal choice for a multitude of projects. It can be used for creating fire-resistant boards, waterproofing surfaces, and insulating walls and roofs. Additionally, it is commonly employed in the production of lightweight concrete, soundproofing panels, and even as a base for self-leveling floors. This product's versatility and durability make it a popular choice for both residential and commercial construction projects.

Okorder.com is a leading wholesale supplier of Magnesium Oxide Cement Recipe, boasting a large inventory to meet the demands of various construction projects. As a reliable source for this product, Okorder.com ensures that customers receive high-quality materials at competitive prices. With their extensive experience in the industry, they are committed to providing excellent customer service and support, making them the go-to supplier for all Magnesium Oxide Cement Recipe needs.

Hot Products