Fused Cast Chrome Magnesite Bricks for Cement Rotary Kiln

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

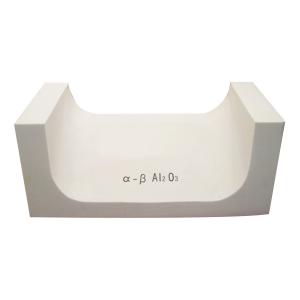

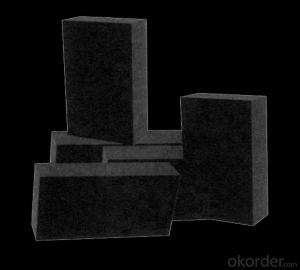

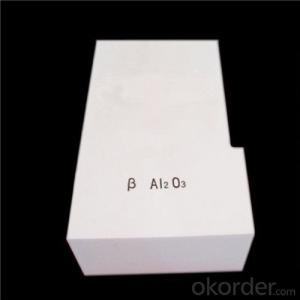

Magnesia chrome brick is mainly made from sintered magnesia and chrome-oxide, by high pressure shaping and chrome-oxide,by high pressure shaping and high temperature firing.According to different requirements the contents of the Cr2O3 can be changed. The product has good specifications for the shock resistance and high temperature performance. It's characterized by the small thermal expansion.The good thermal shock resistance and slag resistance.It is widely used for many industrial furnaces and kilns such as cement kilns,open-hearth furnace and melting furnace for nan-ferrous metals.Extra high temperature firing direct bonded,rebounded,rebounded and semirebonded magnesia-chrome brick,which are made from purity material all or part of the material that is synthesizeed through fusion,pressed with fine ingredients and high pressure and sintered by extra high temperature.

| CONTENT/CODE | MGE-20 | MGE-16 | MGE-12 | MGE-8 | DBMK-A | DBMK-B | DBMK-C | electro-fused rebonded magnesite chrome brick |

| MgO(%>=) | 40 | 45 | 55 | 60 | 80 | 80 | 80 | 75.2 |

| Cr2O3(%>=) | 20 | 16 | 12 | 8 | 6-8 | 6-8 | 6-8 | 13.4 |

| SiO2(%<=) | 2.0 | 3.0 | 3.0 | 1.4 | ||||

| Apparent porosity(%<=) | 22 | 22 | 21 | 21 | 18 | 18 | 18 | 14.5 |

| Cold crushing strength(MPA) | 25 | 25 | 30 | 30 | 40 | 40 | 40 | 59.8 |

| Initial softening temperature(C>=) | 1550 | 1550 | 1550 | 1530 | 1630 | 1630 | 1630 | 1750 |

Application of Magnesite-Chrome Brick

Cement rotary kiln

Non-ferrous furnace

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q: What are the forming methods of refractory materials?

- Basically there are three kinds: grouting molding, casting molding, machine forming, the three methods are applicable to different types of refractory materials, grouting molding for unshaped refractory

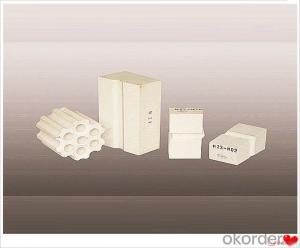

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What are the categories of bricks?

- Fired shale brick as a new building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, loss and high work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, the Jian Ling brick has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: What is the face brick

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: Just what is in the furnace material?

- Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are kiln bricks?

- Kiln brick masonry brick kiln used brick, brick is a brick kiln.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon aluminum

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

Send your message to us

Fused Cast Chrome Magnesite Bricks for Cement Rotary Kiln

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords