Fused Cast AZS (Alumina, Zirconia, Silica) Firebrick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

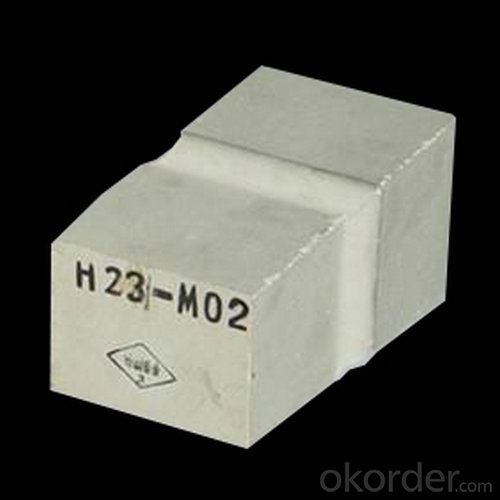

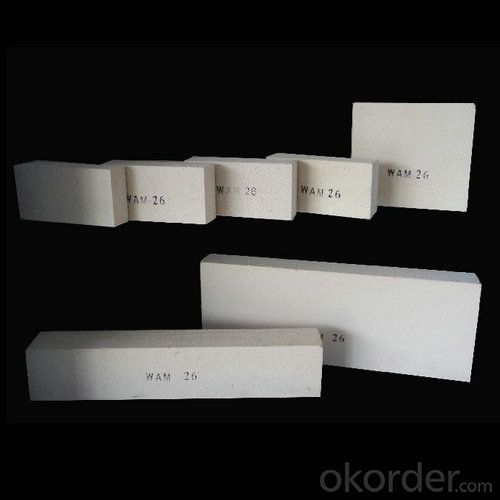

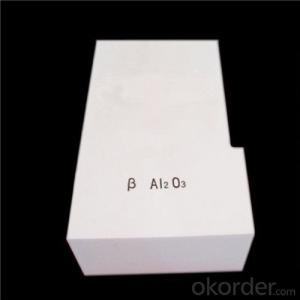

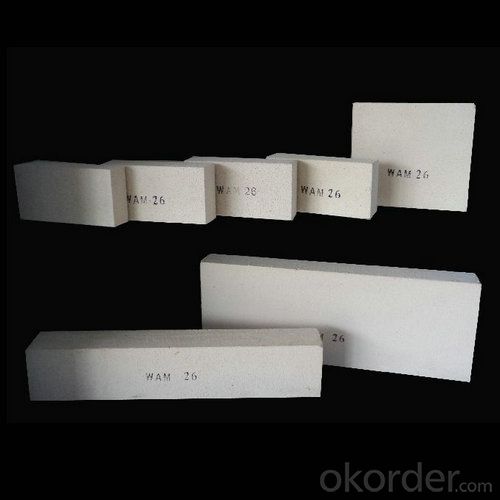

General Information of Fused Cast AZS

CMAX fused cast AZS (alumina, zirconia and silica) firebricks are mainly categorized into 33#, 36# and 41# according to different zirconia's contents from 33% to 41%.

Feature of Fused Cast AZS

High refractoriness

Excellent resistance to corrosion of molten glass

Application of Fused Cast AZS

Glass furnace

Images of Fused Cast AZS

Technical Data of Fused Cast AZS

ITEM AZS-33 AZS-36 AZS-41

Al2O3, % ≥50 ≥49 ≥45

ZrO2, % ≥32.5 ≥35.5 ≥40.5

SiO2, % ≤15.5 ≤13 ≤13

Na2O+K2O, % ≤1.3 ≤1.35 ≤1.3

Bulk Density, g/cm3 ≥3.75 ≥3.85 ≥4

Apparent Porosity, % ≤1.2 ≤1 ≤1.2

Cold Crushing Strength, Mpa ≥300 ≥300 ≥300

Exudating temperature of glass

phase, ℃

≥1400 ≥1400 ≥1410

Bubbling tendency(1300℃x10hr),% 2 2 2

Anti-corrosion rate of glass

liquid(1500℃x36hr), %

1.5 1.4 1.2

Company Introduction

Who CNBM is

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

What CNBM Can Do

We can supply ALL KINDS OF REFRACTORIES BRICK/CASTABLE and CERAMIC FIBER PRODUCTS in high quality and competitive price.

What Certification CNBM Have

FAQ

If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor.

I’m not satisfied with the refractory materials I used before, can you propose more suitable pro

Yes. Please give us the problems you faced, your requirements and the technical data of the products you used before. That we will give you our suggestion and propose the solution based on your special requirements.

What’s the lead time for my order?

It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Can you offer Door-to-Door delivery?

Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

What is the minimum quantity?

There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- How can the silica in zircon sand be removed during the smelting of zirconium corundum?The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: Just what is in the furnace material?

- It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What are kiln bricks?

- Furnace (kiln; furnace; oven) is made of refractory material used for firing products; it is a necessary facility in the formation of ceramic art. Millions of years of human porcelain history, has accumulated rich experience and made kiln style. From the primitive society to open pile burn, burn up like digging to build Steamed Buns flame round kiln, half pour flame kiln, kiln, Banpo horseshoe shaped kiln to duck's egg, indoor gas kiln, kiln kiln electric current, in the continuous improvement in the development of science and technology.

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- A cuboid with stone walls, with mud firing, mostly red, commonly known as "red brick", there are "blue brick". The size of China's standard clay bricks is 240 x 115 * 53mm. The purpose of this size is to ensure that the length and width of the bricks are 4:2:1 (including the width of the 10mm seam). The thickness of brick to brick brick due to multiple titles, length is 240mm, so the thickness of a brick wall called "24" wall thickness of brick and a half wall called "37" wall thickness is the half brick wall is also known as the "one or two wall". Use bricks online to compare some extreme jokes.

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Tile has a long period of cement pollution, a variety of weak acid cleaning can be removed, such as oxalic acid, acetic acid and so on, of course, the use of special cleaning agent is perfect. But the cost is higher.

- Q: What material is good for refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks.

- Q: What's the use of refractory bricks?

- Refractory bricks are mostly used in the lining of furnaces of high temperature industries. Such as iron and steel industry, blast furnace, hot blast furnace, converter, colored reverberatory furnace, rotary kiln, etc.

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

Send your message to us

Fused Cast AZS (Alumina, Zirconia, Silica) Firebrick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords