Fused Cast Zirconia Alumina Brick for Sodium Silicate Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zirconia Alumina Brick Features:

1.Casted by melting raw material in the mold, then cooling and solidification.

2.Strong glass corrosion resistance and high thermal shack stability.

3.Good wear-resistance,dregs-resistance and alkali corrosion resistance.

4.High-purity raw material, barely no pollution.

5.Top quality, long service time.

Zirconia Alumina Brick Applications:

1.Sodium silicate furnace, ceramic frit furnace, glass furnace, etc.

2.Important parts of furnaces where chemical erosion is serious and temperature changes frequently.

3.Lining of glass furnace.

4.The chemical industrial, metallurgical furnaces.

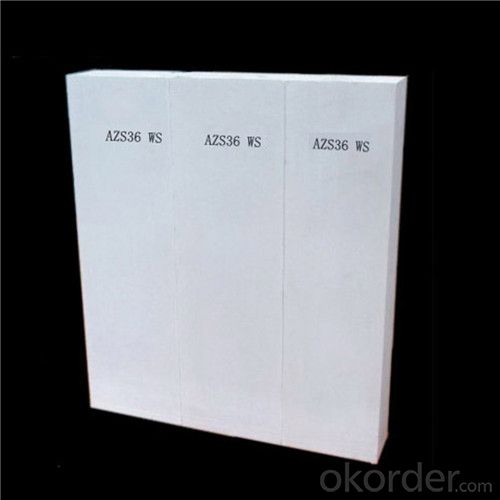

Zirconia Alumina Brick Physical and chemical index:

Item |

unit | Properties | ||||||||||

AZS—33 | AZS—36 | AZS—41 | ||||||||||

Y | H | Y | H | Y | H | |||||||

Al2O3 | % | Residual quantity | ||||||||||

ZrO2 | ≥ | 32 | 35 | 40 | ||||||||

SiO2 | ≤ | 16 | 17 | 13.5 | 14.5 | 13 | 14 | |||||

Na2O | 1.5 | 1.4 | 1.3 | |||||||||

Fe2O3+TiO2+CaO+MgO +Na2O+K2O+B2O3 | 2.5 | 3.0 | 2.5 | 3.0 | 2.5 | 3.0 | ||||||

Glass phase exudate temperature | ≥ | °C | 1400 | 1080 | 1400 | 1100 | 1400 | 1150 | ||||

% Thermal expansion rate | 1000°C | 0.8 | ||||||||||

1500°C | 0.8 | |||||||||||

Cold Crushing strength Mpa | 350 | |||||||||||

Bulk density,g/cm3 | PT,QX | ≥ | KG/dm3 | 3.40 | 3.30 | 3.45 | 3.4 | 3.55 | 3.50 | |||

MS | 3.50 | 3.45 | 3.60 | 3.55 | 3.70 | 3.65 | ||||||

WS | 3.60 | 3.55 | 3.70 | 3.65 | 3.80 | 3.75 | ||||||

True density,g/cm3 | 3.8-3.9 | |||||||||||

Crystal phase composition | Item | Inclined zircon | Alpha corundum | Glass phase | ||||||||

AZS—33 | 32 | 47 | 21 | |||||||||

AZS—41 | 40 | 43 | 17 | |||||||||

Application | PT,QX | ZWS | WS | |||||||||

sodium silicate furnace,ceramic frit furnace , glass furnace,and other furnaces | ||||||||||||

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets

- Q: How are qualitative and qualitative refractories understood?

- Unshaped refractory products, referred to as bulk loading, are made at the place of use for the required shapes and for heat treatment, such as castable, ramming, projection, spray, refractory clay, etc..

- Q: What are the forming methods of refractory materials?

- Casting molding is suitable for casting brick, electric melting brick and so on. And the machine press forming is the most widely used. The common refractory brick, clay brick and other sintered brick are adopted this method.

- Q: What are the categories of bricks?

- Fired shale brick as a new building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, loss and high work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, the Jian Ling brick has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Just what is in the furnace material?

- It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are kiln bricks?

- Refractory materials are generally divided into two kinds, namely unshaped refractory and shaped refractory. Unshaped refractory castable is also called, is composed of a variety of aggregate or aggregate and one or more adhesive powder particles, and must use one or more liquid with stirring, has strong liquidity. Refractory materials generally refers to the shape of a refractory brick, standard rules, can also according to need to be cut when the temporary processing.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon aluminum

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q: What's the use of refractory bricks?

- Refractory bricks are mostly used in the lining of furnaces of high temperature industries. Such as iron and steel industry, blast furnace, hot blast furnace, converter, colored reverberatory furnace, rotary kiln, etc.

- Q: Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

Fused Cast Zirconia Alumina Brick for Sodium Silicate Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords