High Alumina Brick for Alumina Making Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Bricks for Alumina Making Furnaces

Composite of High Alumina Bricks for Alumina Making Furnaces

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks for Alumina Making Furnaces

Low thermal conductivity

Excellent acid and base slagging resistance

Excellent thermal shock resistance

Excellent mechanical strength

Wear and erosion resistant

Application of High Alumina Bricks for Alumina Making Furnaces

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

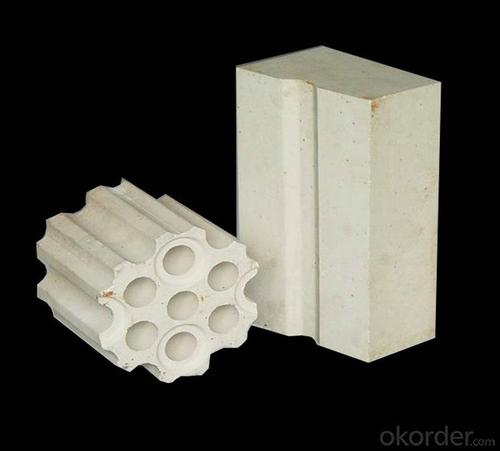

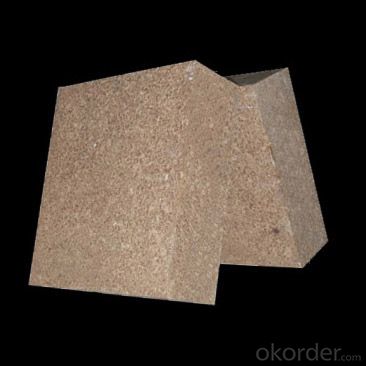

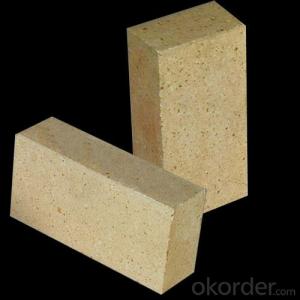

High Alumina Bricks for Alumina Making Furnaces Images

Specification of High Alumina Bricks for Alumina Making Furnaces

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks for Alumina Making Furnaces

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q6:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q7:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q: What are the grades of high alumina bricks?

- According to the size of high aluminum brick is divided into: standard brick, special-shaped brick.

- Q: What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q: What are the requirements for Rubble backfill height?

- 1, filling thickness is not greater than 50cm.2, filling, the use of layered filling.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- The structural strength of high temperature is evaluated by loading softening point. Load softening point is that under certain pressure (2 kg/ cm 2 = 0.2MPa) under the condition of heating rate to heating, measured the sample deformation (deformation for the original sample 0.6%) temperature. This temperature is called the softening point of the refractory. Sample size is Phi 36 x 50mm.

- Q: What kind of material is the general metal case?

- We usually discuss the electromagnetic radiation of computer enclosures, mainly RF radiation, followed by MF leakage.Switch signal of RF radiation from computer high-speed leakage, such as one of the energy radiation is CPU frequency, graphics, display output line, keyboard, is the source of the operating characteristics of the computer leaked out, is also the main part of computer security.For the absorption of radio frequency radiation, the best is the use of copper materials, the use of other metals can also, thickness enough on the line.The most vulgar description is that people can sit in the case is a good thing.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Refractory bricks are stone powder and clay paste. They are fired in a kiln of 1300 degrees. The upper limit is 1500 degrees above normal pressureRefractory bricks - refractory materials of a specified shape and size.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

Send your message to us

High Alumina Brick for Alumina Making Furnaces

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords