All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

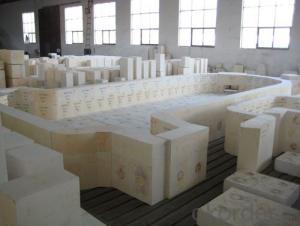

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the applications of refractory plastics?

Refractory plastics find applications in a variety of industries where high-temperature resistance, thermal insulation, and corrosion resistance are crucial. They are commonly used in the manufacturing of furnaces, kilns, incinerators, and other high-temperature equipment. Refractory plastics are also employed for lining and repairing refractory structures, such as boilers, chimneys, and reactors. Additionally, they are utilized in the production of foundry molds, crucibles, and other refractory shapes.

How are refractory coatings for thermal cycling resistance applied?

Refractory coatings for thermal cycling resistance are typically applied through various methods such as spraying, brushing, or dipping. These coatings are carefully formulated to withstand extreme temperatures and rapid temperature changes, ensuring enhanced durability and protection for the underlying materials.

What are the factors affecting the lifespan of refractory materials?

There are several factors that can affect the lifespan of refractory materials. These include the type and quality of the refractory material, the temperature and environment in which it is used, the frequency and intensity of thermal cycling, the presence of corrosive or abrasive substances, and the proper installation and maintenance of the refractory material.

Wholesale Refractory Materials from supplier in Italy

We offer a wide range of high-quality refractory materials that are used in various industries such as steel, cement, glass, and petrochemicals. Our product portfolio includes refractory bricks, castables, ceramic fibers, and insulation materials, among others.

In addition to offering a comprehensive range of products, we also provide technical support to our customers. Our team of experts is well-versed in the application and installation of refractory materials, and we offer guidance and assistance to ensure optimal performance and longevity of our products.

Furthermore, we understand the importance of timely and accurate quotations in the procurement process. Our dedicated sales team is committed to providing competitive pricing and quick response times for all inquiries. We strive to offer the best value for money to our customers.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This allows us to source and deliver refractory materials efficiently and effectively, ensuring a seamless procurement experience for our customers in Italy.

With years of operation in Italy, we have gained invaluable market expertise and have built strong relationships with customers and partners. We understand the unique requirements and challenges of the Italian market and tailor our offerings accordingly.

In summary, as a leading supplier of refractory materials in Italy, we are committed to providing a comprehensive range of products and services, backed by technical support and market expertise. With our strong focus on sales, quotations, and customer satisfaction, we aim to be the preferred choice for all refractory material needs in Italy.

In addition to offering a comprehensive range of products, we also provide technical support to our customers. Our team of experts is well-versed in the application and installation of refractory materials, and we offer guidance and assistance to ensure optimal performance and longevity of our products.

Furthermore, we understand the importance of timely and accurate quotations in the procurement process. Our dedicated sales team is committed to providing competitive pricing and quick response times for all inquiries. We strive to offer the best value for money to our customers.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This allows us to source and deliver refractory materials efficiently and effectively, ensuring a seamless procurement experience for our customers in Italy.

With years of operation in Italy, we have gained invaluable market expertise and have built strong relationships with customers and partners. We understand the unique requirements and challenges of the Italian market and tailor our offerings accordingly.

In summary, as a leading supplier of refractory materials in Italy, we are committed to providing a comprehensive range of products and services, backed by technical support and market expertise. With our strong focus on sales, quotations, and customer satisfaction, we aim to be the preferred choice for all refractory material needs in Italy.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Jordan

- Refractory Bricks in Germany

- Raw Materials For Refractory in Zimbabwe

- Refractory Bricks in Israel

- Monolithic Refractories in Papua New Guinea

- Raw Materials For Refractory in Egypt

- Ceramic Fiber Products in Kenya

- Raw Materials For Refractory in Poland

- Monolithic Refractories in Serbia