Fused Cast Refractor Bricks for Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fused Cast Refractor Bricks for Glass Furnace

| Place of Origin: | China (Mainland) | Shape: | Brick, Customized | Material: | Alumina Block |

| SiO2 Content (%): | 16% | Al2O3 Content (%): | Remain | CaO Content (%): | 1.0% |

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° | Model Number: | CXD-GGYZ11 | Brand Name: | |

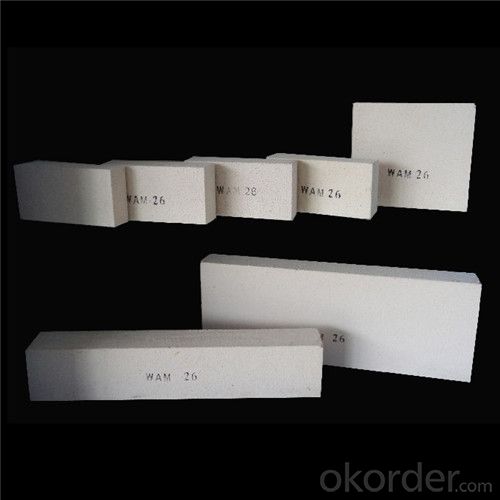

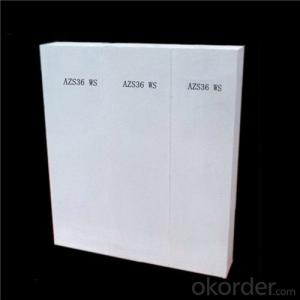

| Name: | fused cast azs refractor bricks | Type: | Manufacturer | Color: | White |

| Certificate: | ISO9001 | Sample: | Available | ZrO2: | ≥32% |

| Compress crushing strength: | ≥350mpa | 0.2Mpa Refractoriness under load: | 1700C | Contact: | Daisy |

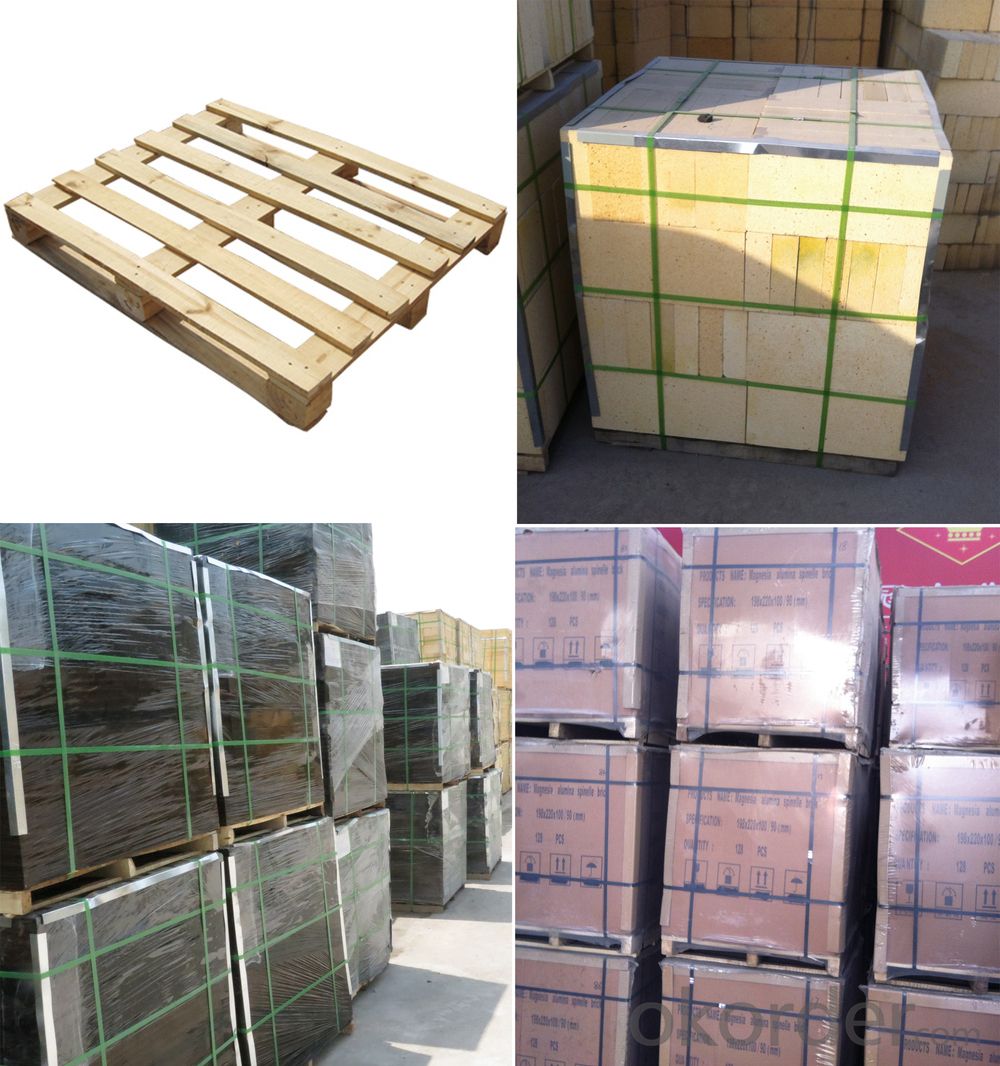

Packaging & Delivery

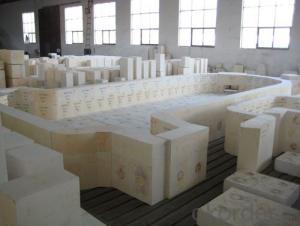

| Packaging Details: | Fumigated wooden pallet, plastic shrink film protected outside, then the straps. Finally make the wooden pallet (95*95cm, 95*100cm) , usually 1.5T per pallet, 20T per container , or as your requirements. |

| Delivery Detail: | within 20 working days after deposit |

Product Description

| Description of fused cast azs refractor bricks |

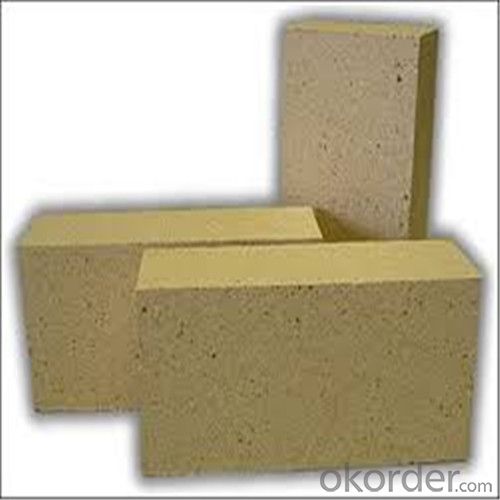

The fused cast azs refractor bricks are made of alumina powder, zirconia sand and additive etc.

| Applications of fused cast azs refractor bricks |

The fused cast azs refractor bricks are mainly used for Glass furnace tank

| Advantages of fused cast azs refractor bricks |

1. Good corrossion to glass liquid resistance

2. Low pollution

3. Good thermal shock resistance

4. High hot crush strength

| Physical and Chemical Indexes of fused cast azs refractor bricks |

| Item | Unit | Indexes | ||

| AZS-33 | AZS-36 | |||

| ZrO2 | % | ≥32 | ≥35 | |

| SiO2 | % | ≤16 | ≤14 | |

| Al2O3 | % | Remain | Remain | |

| NaO2 | % | ≤1.5 | ≤1.6 | |

| Fe2O3+TiO2+CaO+k2O | % | ≤2.5 | ≤2.5 | |

| Compress crushing strength | Mpa | ≥350 | ≥350 | |

| Exudationtemperature of glassphase | ℃ | >1400 | >1400 | |

| Anti Liquid glass erosion resistance | mm | ≤1.6 | ≤1.5 | |

| (1500℃*36h) | ||||

| Bulk density | Common casting | % | ≥3.4 | ≥3.5 |

| Inclined casting | % | ≥3.45 | ≥3.55 | |

| No piping casting | % | ≥3.7 | ≥3.8 | |

| 0.2Mpa Refractoriness under load | ℃ | 1700 | 1700 | |

Packaging & Shipping

Our Services

1. Quality assurance,CX REFRACTORY use high grade raw material. All products are ISO qualified.

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly,save much intermediate fees.

4. Professional and experienced service team, specialized in refractory production since 1986.

5. Large production capacity, short lead time of products.

6. 24*7 online service.

7. OEM service available.

FAQ

1. What’s the payment?

Usually T/T, others could be discussed.

2. When will you deliver the goods?

The delivery time will be determined according to the quantity of the order.

3. Do you provide samples?

Yes, samples are available.

4. How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

5. Do you accept OEM?

Yes, we can do OEM.

- Q: What is brick power, half brick power and full brick power difference?

- All brick power up to 500 watts up and down. The internal circuit is tight and heating, the device has good adhesion, the circuit is more advanced, and the efficiency is high, so it can achieve small size and high power.

- Q: How are qualitative and qualitative refractories understood?

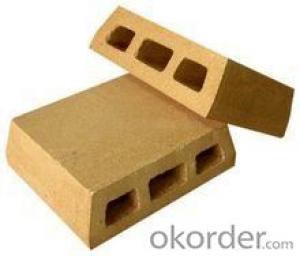

- Shaped refractory products, such as fired brick, fused brick (Rong Zhuzhuan), refractory insulation bricks, as well as experimental and industrial crucibles, utensils and other special products.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: What is the face brick

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: What are kiln bricks?

- Kiln brick masonry brick kiln used brick, brick is a brick kiln.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- A cuboid with stone walls, with mud firing, mostly red, commonly known as "red brick", there are "blue brick". The size of China's standard clay bricks is 240 x 115 * 53mm. The purpose of this size is to ensure that the length and width of the bricks are 4:2:1 (including the width of the 10mm seam). The thickness of brick to brick brick due to multiple titles, length is 240mm, so the thickness of a brick wall called "24" wall thickness of brick and a half wall called "37" wall thickness is the half brick wall is also known as the "one or two wall". Use bricks online to compare some extreme jokes.

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: What material is good for refractory bricks?

- No definite answer can be given, because any furnace is not made of only one refractory brick and needs a different fire brick to be used with each other.

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

Send your message to us

Fused Cast Refractor Bricks for Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords