High Quality Magnesite Bricks for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Used for Regenerator of Glass Furnace Supply High Quality Magnesite Bricks

CMAX Magnesia chrome bricks are made from chrome and magnesia. Magnesia chrome brick is mainly made from sintered magnesia and chrome-oxide, by high pressure shaping and chrome-oxide,by high pressure shaping and high temperature firing.According to different requirements the contents of the Cr2O3 can be changed. The product has good specifications for the shock resistance and high temperature performance. It's characterized by the small thermal expansion.The good thermal shock resistance and slag resistance.It is widely used for many industrial furnaces and kilns such as cement kilns,open-hearth furnace and melting furnace for nan-ferrous metals.Extra high temperature firing direct bonded,rebounded,rebounded and semirebonded magnesia-chrome brick,which are made from purity material all or part of the material that is synthesizeed through fusion,pressed with fine ingredients and high pressure and sintered by extra high temperature.

Product Applications:

Magnesia chrome bricks are ideal for use in the below applications

Metallurgy industry of open-hearth furnace top , electric furnace roof, Mixer linings etc.

RH, VOD, AOD, and other refining installations;

Non-ferrous metallurgical furnace, vacuum treatment equipment;

Building materials , glass furnace regenerator; cement rotary kiln calcination etc.

Product Advantages:

CNBM has success in its magnesia chrome bricks due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Low porosity, high compressive strength, flexural strength of high pressure, good bulk stability;

Good thermal shock resistance, anti-spalling

Easy-to-skin hanging in the kiln, and low thermal conductivity;

High temperature of refractoriness under load.

Ultra-high-temperature firing, high direct binding rate, high refractoriness and corrosion resistance.

Strong resistance against alkaline substances, the acid resistance better than the magnesia refractories.

Product Specifications:

Fused-rebonded Magnesia Chrome Brick | |||||||

ITEM | FRMC-12 | FRMC-14 | FRMC-16 | FRMC-18 | FRMC-20 | FRMC-22 | FRMC-26 |

MgO, % ≥ | 68 | 65 | 60 | 58 | 55 | 50 | 45 |

Cr2O3, % ≥ | 12 | 14 | 16 | 18 | 20 | 22 | 26 |

SiO2, % ≤ | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.5 | 1.5 |

Apparent Porosity, % ≤ | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

Bulk Density, g/cm3 ≥ | 3 | 3.05 | 3.08 | 3.1 | 3.15 | 3.2 | 3.25 |

Cold Crushing Strength, Mpa ≥ | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

Refractoriness Under Load, ℃ ≥ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

Product Picture

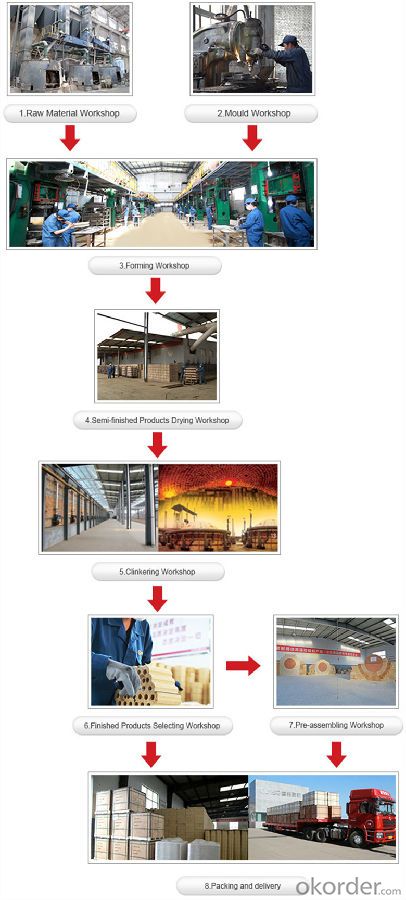

Produce Processing

- Q: Brick price?

- There are various series of unshaped refractory gunning, magnesia ramming material, mending material, coating material, dry lining material, composite refining agent, covering agent, tundish and tundish slag wall, ladle drainage sand and electric furnace taphole filler etc..

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- Manufacture of various refractory magnesia brick Magnesium Oxide, mainly from magnesite.

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: Magnesia brick

- Mainly used for basic open hearth, furnace bottom and furnace wall oxygen converter steelmaking, the permanent lining of non-ferrous metal smelting furnace, high temperature tunnel kiln, calcined magnesia brick and cement rotary kiln, furnace bottom and furnace wall, glass furnace regenerator etc..

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Magnesia brick (magnesite brick) basic refractories Magnesium Oxide content of more than 90%, with the main crystalline phase of periclase

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.Fused magnesia brick brick has compact structure, high mechanical strength, low impurity content, mainly used for the storage of large glass kiln

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- If you want to know the indicators of chrome brick, magnesia chrome brick must know you are in what furnace above, there is in what position

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

Send your message to us

High Quality Magnesite Bricks for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches