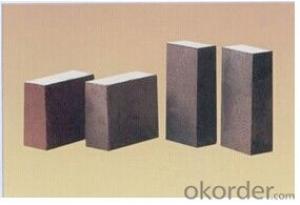

Magnesite Brick for Glass Furnace Regenerator

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Brief discription for Alumina Fire Brick

CNBM Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%.

CNBM Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for Alumina Fire Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high aluminia bricks

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

Why us

Professional fire brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

- Q: What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- Different grades of burned magnesia brick is mainly made of magnesia binder with different taste, there is not a big difference. However, the physical and chemical properties of binders should be controlled well!

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: High purity magnesia brick masonry mortar for what?

- You try a mixture of aluminum phosphate. It itself is the main component of aluminum, which can not cause pollution. We use high temperature electric stove to bond with this.But this 800 degree won't be sintered. It won't sinter until more than 1000 degrees.

- Q: Manufacture of various refractory magnesia brick mainly comes from Magnesium Oxide, what kind of ore?

- The ore quality requirements of MgO = 41%, CaO = 6%, SiO2 = 5%. The resources of magnesite in China are rich. The types of deposits include sedimentary metamorphic deposits, sedimentary hydrothermal metasomatic deposits and weathering leaching deposits.

- Q: With different capacitance magnesia brick brick

- It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: How to identify the fused magnesia brick and sintered magnesia brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.Fused magnesia brick brick has compact structure, high mechanical strength, low impurity content, mainly used for the storage of large glass kilnHigh temperature area of the room. The fused magnesia is made of high quality magnesia as raw material. It is made by melting. The English name is fused magnesite. Magnesium hydroxide from magnesite or brucite or from sea water is calcined at high temperature. Strong hydration resistance.

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- If you want to know the indicators of chrome brick, magnesia chrome brick must know you are in what furnace above, there is in what position

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- The main varieties of common magnesia brick, magnesia brick, magnesia brick, magnesia brick high pure grade. Product main mineral phase is periclase, volume has high stability and anti erosion ability. Literature is widely used in steelmaking, non-ferrous metal smelting and other high-temperature industrial furnace.

Send your message to us

Magnesite Brick for Glass Furnace Regenerator

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords