All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

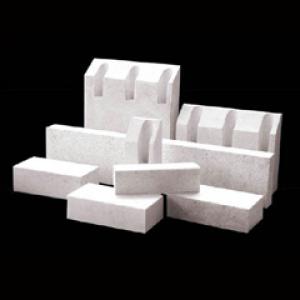

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common techniques used for refractory material installation?

Some common techniques used for refractory material installation include: casting, gunning, ramming, and bricklaying. Casting involves pouring a liquid refractory material into a mold to create a specific shape. Gunning uses a high-pressure gun to spray refractory material onto a surface. Ramming involves compacting refractory material into a mold or onto a surface using a hammer or pneumatic rammer. Bricklaying involves arranging bricks or precast shapes in a specific pattern to form a refractory lining. Each technique is chosen based on the specific application and requirements of the refractory material being installed.

What is the role of refractory materials in furnace design?

Refractory materials play a crucial role in furnace design by providing insulation and heat resistance, allowing the furnace to reach and maintain high temperatures without damaging its structure. They also help to contain and distribute heat evenly within the furnace, optimizing its efficiency and preventing heat loss. Additionally, refractory materials protect the furnace walls from chemical corrosion and erosion caused by the harsh conditions inside the furnace.

How are refractory mortars used in thermal insulation linings?

Refractory mortars are used in thermal insulation linings as a binding agent to hold together the refractory bricks or other insulation materials. They are applied between the joints of the bricks to create a strong and durable structure. Refractory mortars also play a crucial role in enhancing the insulation properties of the lining by filling any gaps or voids, preventing heat loss and providing a more efficient thermal barrier.

What are the challenges faced by refractory materials in the incineration industry?

One of the main challenges faced by refractory materials in the incineration industry is the high temperatures and corrosive environments they are exposed to. Incineration processes generate extreme heat, reaching temperatures of up to 1,200 degrees Celsius, which can cause thermal shock and wear on refractory linings. Additionally, the presence of aggressive gases and chemicals in the combustion process can lead to chemical attack and erosion of the refractory materials. These challenges require refractory materials to have excellent thermal shock resistance, chemical resistance, and mechanical strength to withstand the harsh conditions in incineration plants.

Wholesale Refractory Materials from supplier in Mozambique

Whether you are involved in the construction, mining, or industrial sectors, our range of Refractory Materials can cater to your specific requirements. We offer a wide variety of refractory bricks, castables, mortars, and insulation materials, sourced from top manufacturers worldwide.

Our team of experts is dedicated to providing personalized service and technical support to ensure that you receive the most suitable products for your applications. We understand the unique challenges and conditions in Mozambique and can assist you in selecting the optimal refractory solutions for your projects.

In addition to supplying high-quality products, we also offer competitive pricing and efficient logistics to ensure timely delivery of your orders. Our strong partnership with reputable shipping companies and local transportation networks enables us to meet your deadlines and reduce any potential disruptions to your operations.

Furthermore, as a subsidiary of CNBM, we have access to a vast network of resources and industry expertise. Our close collaboration with CNBM's research and development centers allows us to stay at the forefront of technological advancements in refractory materials. This knowledge translates into added value for our customers, as we can provide innovative solutions and recommend the best practices for your projects.

Whether you require refractory materials for kilns, furnaces, boilers, or any other high-temperature applications, we have the knowledge and products to meet your needs. Contact us today to discuss your requirements and let us assist you in sourcing the right refractory materials for your projects in Mozambique.

Our team of experts is dedicated to providing personalized service and technical support to ensure that you receive the most suitable products for your applications. We understand the unique challenges and conditions in Mozambique and can assist you in selecting the optimal refractory solutions for your projects.

In addition to supplying high-quality products, we also offer competitive pricing and efficient logistics to ensure timely delivery of your orders. Our strong partnership with reputable shipping companies and local transportation networks enables us to meet your deadlines and reduce any potential disruptions to your operations.

Furthermore, as a subsidiary of CNBM, we have access to a vast network of resources and industry expertise. Our close collaboration with CNBM's research and development centers allows us to stay at the forefront of technological advancements in refractory materials. This knowledge translates into added value for our customers, as we can provide innovative solutions and recommend the best practices for your projects.

Whether you require refractory materials for kilns, furnaces, boilers, or any other high-temperature applications, we have the knowledge and products to meet your needs. Contact us today to discuss your requirements and let us assist you in sourcing the right refractory materials for your projects in Mozambique.

Hot Search

- Monolithic Refractories in Czech Republic

- Ceramic Fiber Products in Lebanon

- Refractory Bricks in Finland

- Raw Materials For Refractory in Namibia

- Raw Materials For Refractory in Slovenia

- Ceramic Fiber Products in Mauritania

- Refractory Bricks in Mozambique

- Ceramic Fiber Products in Greece

- Raw Materials For Refractory in Cyprus

- Monolithic Refractories in Maldives