All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What is the function of organic fibers in improving the properties of refractory products?

Organic fibers play a crucial role in enhancing the properties of refractory products. They act as binders, reinforcing agents, and thermal stabilizers, improving the overall strength, thermal shock resistance, and dimensional stability of the refractory material. The addition of organic fibers helps in reducing cracking, spalling, and erosion during high-temperature operations, thus prolonging the lifespan of refractory products. Furthermore, organic fibers also contribute to improved workability, ease of installation, and better resistance to mechanical stress, making them an essential component in the manufacturing of high-quality refractories.

What are the advantages of using yttrium fluoride as a raw material in refractory production?

One of the advantages of using yttrium fluoride as a raw material in refractory production is its high melting point, which makes it suitable for applications that require resistance to extreme temperatures. Additionally, yttrium fluoride has excellent thermal stability and chemical resistance, making it a reliable material for refractory products. Its unique properties also contribute to improved strength and durability, making it an advantageous choice for refractory production.

How do raw materials affect the resistance to alkali attack of refractory products?

Raw materials can have a significant impact on the resistance to alkali attack of refractory products. Certain raw materials, such as high alumina content materials, have a strong resistance to alkali attack due to their chemical composition and ability to form protective layers. On the other hand, raw materials with a high silica content are more susceptible to alkali attack and may have a lower resistance. The selection and composition of raw materials play a crucial role in determining the overall resistance of refractory products to alkali attack.

What are refractory raw materials?

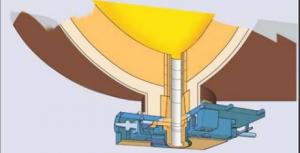

Refractory raw materials are substances that have a high melting point and excellent thermal stability, making them suitable for use in industries that require materials capable of withstanding extremely high temperatures and harsh conditions. These materials are used in the production of refractory products, such as bricks, castables, and fibers, which are essential components in furnaces, kilns, and other high-temperature applications.

Wholesale Raw Materials For Refractory from supplier in Cyprus

We are committed to providing excellent customer service and building long-lasting relationships with our clients. Our team is always available to answer any questions, provide technical assistance, and offer solutions to any challenges you may encounter during your projects.

At CNBM Cyprus, we understand the importance of timely delivery and efficient logistics. We have established strong partnerships with reliable shipping companies and logistics providers to ensure that your Raw Materials For Refractory products reach you in a timely manner and in perfect condition.

Furthermore, we prioritize the quality of our products and the satisfaction of our customers. We work closely with trusted suppliers and conduct rigorous quality control checks to ensure that our Raw Materials For Refractory meet the highest industry standards. Our goal is to provide you with durable and reliable materials that will withstand high temperatures and harsh conditions.

Whether you're in need of refractory bricks, castables, mortars, or any other raw materials for your refractory projects, CNBM Cyprus is your trusted partner. Contact us today to discuss your requirements and let us provide you with the best solutions for your needs.

At CNBM Cyprus, we understand the importance of timely delivery and efficient logistics. We have established strong partnerships with reliable shipping companies and logistics providers to ensure that your Raw Materials For Refractory products reach you in a timely manner and in perfect condition.

Furthermore, we prioritize the quality of our products and the satisfaction of our customers. We work closely with trusted suppliers and conduct rigorous quality control checks to ensure that our Raw Materials For Refractory meet the highest industry standards. Our goal is to provide you with durable and reliable materials that will withstand high temperatures and harsh conditions.

Whether you're in need of refractory bricks, castables, mortars, or any other raw materials for your refractory projects, CNBM Cyprus is your trusted partner. Contact us today to discuss your requirements and let us provide you with the best solutions for your needs.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Finland

- Refractory Bricks in Bengal

- Raw Materials For Refractory in Bahrain

- Ceramic Fiber Products in Malaysia

- Monolithic Refractories in Netherlands

- Refractory Bricks in Tanzania

- Refractory Bricks in Swaziland

- Monolithic Refractories in Palestine

- Monolithic Refractories in Colombia