All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

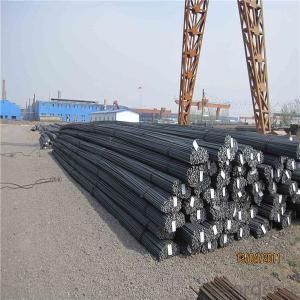

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel rebars used in the construction of tunnels for road transportation systems?

Steel rebars are used in the construction of tunnels for road transportation systems to reinforce the concrete structures. These rebars provide tensile strength to the concrete, allowing it to withstand the pressure and weight exerted on the tunnel. They help prevent cracks and ensure the structural integrity of the tunnel, making it safe and durable for road transportation.

What is the impact of improper lap splicing on the load-carrying capacity of steel-reinforced concrete beams?

Improper lap splicing can significantly decrease the load-carrying capacity of steel-reinforced concrete beams. It can lead to reduced structural integrity, increased vulnerability to cracking, and potential failure under heavy loads. This is because lap splicing is crucial for transferring the load from one reinforcing bar to another, ensuring the reinforcement works together effectively. When done improperly, it weakens the bond between bars, compromises the overall strength of the beam, and compromises the safety of the structure.

How do you estimate the total weight of steel rebars required for a large construction project?

To estimate the total weight of steel rebars required for a large construction project, several factors need to be considered. Firstly, the structural drawings and specifications of the project should be thoroughly examined to determine the quantity and size of rebars needed for each element. This information can be used to create a detailed rebar schedule.

Next, the weight per unit length of each rebar size should be known, which can be obtained from industry standards or manufacturers' catalogs. By multiplying the weight per unit length with the total length of each rebar size required, the weight for each size can be calculated.

Finally, the weights of all the rebars for different sizes are summed up to obtain the total weight of steel rebars required for the project. It is essential to account for any wastage or extra reinforcement needed due to construction practices or design requirements.

It is important to note that accurate estimation also depends on the expertise and experience of the estimator, as well as considering any specific project conditions or variables that may affect the weight estimation.

Wholesale Steel Rebars from supplier in Mozambique

Our team of experts is committed to providing the highest quality Steel Rebars that meet international standards. We source our products from top manufacturers, ensuring that they are of the highest quality and durability. Additionally, we have a strong supply chain network that allows us to deliver the products to your desired location in a timely manner.

In addition to supplying Steel Rebars, we also offer comprehensive sales, quotation, and technical support services. Our dedicated team is always ready to assist you with any inquiries or concerns you may have. We understand the importance of providing excellent customer service and strive to exceed your expectations.

Furthermore, as a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a convenient one-stop solution for all your Steel Rebars procurement needs. This means that you can rely on us for not only supplying the products but also for any additional services or support you may require.

We take pride in our commitment to sustainability and environmental responsibility. Our Steel Rebars are sourced from reputable manufacturers who adhere to strict environmental and ethical standards. We believe in promoting sustainable practices and ensuring the well-being of our planet.

Whether you are a contractor, builder, or project manager, we are confident that our Steel Rebars will meet your needs and exceed your expectations. Contact us today to learn more about our products and services and how we can assist you with your Steel Rebars procurement needs in Mozambique.

In addition to supplying Steel Rebars, we also offer comprehensive sales, quotation, and technical support services. Our dedicated team is always ready to assist you with any inquiries or concerns you may have. We understand the importance of providing excellent customer service and strive to exceed your expectations.

Furthermore, as a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a convenient one-stop solution for all your Steel Rebars procurement needs. This means that you can rely on us for not only supplying the products but also for any additional services or support you may require.

We take pride in our commitment to sustainability and environmental responsibility. Our Steel Rebars are sourced from reputable manufacturers who adhere to strict environmental and ethical standards. We believe in promoting sustainable practices and ensuring the well-being of our planet.

Whether you are a contractor, builder, or project manager, we are confident that our Steel Rebars will meet your needs and exceed your expectations. Contact us today to learn more about our products and services and how we can assist you with your Steel Rebars procurement needs in Mozambique.