Fused Cast Brick - MS33 Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Fused Cast Brick

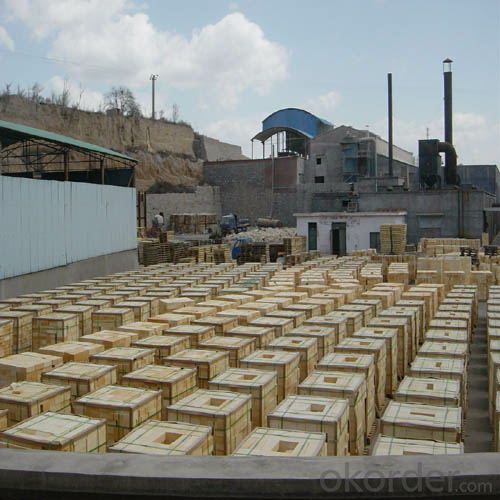

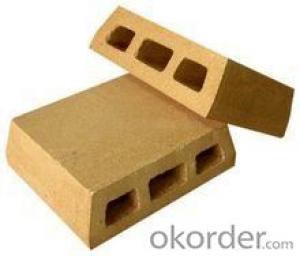

Our fused cast brick-MS33 (alumina, zirconia and silica) firebricks aremainly categorized into 33#, 36# and 41# according to different zirconia'scontents from 33% to 41%. Featuring huge volume density, high compressivestrength, good thermal stability and strong impact resistance. It can be madeinto any specification defined by users to fit for different demands. It also has the capacity of maintainingexcellent mechanical behavior under high temperature,

Features ofFused Cast Brick

High refractoriness

Excellentresistance to corrosion of molten glass

Excellent thermal stability

Applicationof Fused Cast Brick

Our fused cast brick mainly used in:

Glass furnace

Fused Cast Brick-MS33 | ||

Physical Properties: |

|

|

Bubbling Tendency(1300℃×10hrs) | % | 2 |

Apparent Porosity, % | % | ≤1.2 |

Cold Crushing Strength | Mpa | ≥300 |

Exudating Temperature of Glass Phase | % | ≥1400 |

Anti-corrosion Rate of Glass Liquid(1500℃×26hrs) | % | 1.5 |

Density | g/cm3 | ≥3.75 |

Chemical Analysis: |

|

|

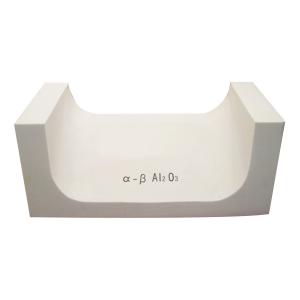

Al2O3 | % | ≥50 |

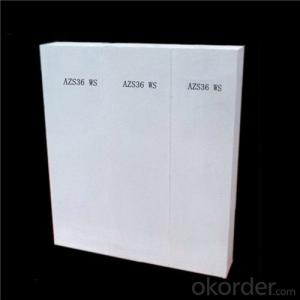

ZrO2 | % | ≥32.5 |

SiO2 | % | ≤15.5 |

Na2O+K2O | % | ≤1.3 |

Note: | ||

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.It is in the production process, zirconium corundum bricks are likely to cause pollution.Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What is brick power, half brick power and full brick power difference?

- Power module. Small size, high power. General use should order additional storage energy, heat dissipation, etc.. Dimensions such as brick, so called brick power supply. Half brick power supply is half the size of all brick power supply.

- Q: How are qualitative and qualitative refractories understood?

- Shaped refractory products, such as fired brick, fused brick (Rong Zhuzhuan), refractory insulation bricks, as well as experimental and industrial crucibles, utensils and other special products.

- Q: What are the forming methods of refractory materials?

- Basically there are three kinds: grouting molding, casting molding, machine forming, the three methods are applicable to different types of refractory materials, grouting molding for unshaped refractory

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.

- Q: What is the face brick

- According to the shape and size can be divided into ordinary brick, standard brick, etc. can be used as a specific type of building furnace and various thermal equipment of high temperature building materials and structural materials, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size.

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q: What material is good for refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks.

- Q: What's the use of refractory bricks?

- Refractory material of a certain shape and size.According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.For example, refractory clay brick, high alumina brick, brick, brick etc..

Send your message to us

Fused Cast Brick - MS33 Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords