All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

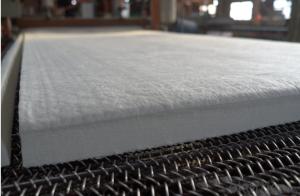

- - Ceramic Fiber Products

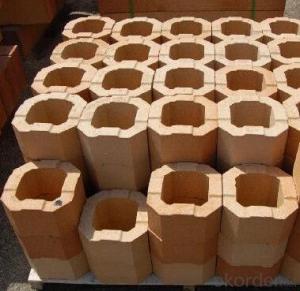

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How are refractory materials inspected for quality control?

Refractory materials are inspected for quality control through a combination of visual inspection, physical testing, and analysis. This involves checking for any defects, cracks, or inconsistencies in the materials' surface, dimensions, and composition. Various techniques such as ultrasonic testing, X-ray inspection, and hardness testing may be used to assess the structural integrity and ensure the materials meet the required specifications. Additionally, refractory materials may undergo thermal cycling tests, corrosion resistance assessment, and performance evaluation in simulated operational conditions to ensure their durability and suitability for specific applications.

How do refractory materials contribute to the performance of rocket engines?

Refractory materials play a crucial role in enhancing the performance of rocket engines by withstanding and containing the extremely high temperatures generated during combustion. These materials, such as ceramics or metal alloys, are heat-resistant and can endure the intense heat and pressure without deforming or deteriorating. By efficiently insulating the engine's components, refractory materials prevent heat transfer to sensitive parts, ensuring the engine operates at optimal temperatures. Additionally, they aid in maintaining structural integrity, preventing damage caused by thermal stress or erosion. Overall, refractory materials enable rocket engines to function reliably and efficiently in extreme conditions, contributing to their overall performance.

What are the common types of refractory castables?

The common types of refractory castables include low cement castables, ultra-low cement castables, conventional castables, insulating castables, and self-flowing castables.

What are the challenges faced by refractory materials in the defense industry?

Refractory materials face several challenges in the defense industry, including extreme temperatures and harsh environments, high mechanical stress, erosion, and abrasion. These materials need to withstand the intense heat generated by weapons systems, such as rocket engines and jet turbines, while maintaining their structural integrity. Additionally, they must be resistant to chemical attack and corrosion from various fuels and oxidizers. The constant exposure to high-velocity gases, abrasive particles, and shock waves also poses challenges in terms of erosion and wear resistance. Overall, the defense industry requires refractory materials that can withstand extreme conditions and provide long-lasting performance to ensure the safety and effectiveness of military equipment and systems.

Wholesale Refractory Materials from supplier in Tunisia

Whether you are looking for high-quality bricks, castables, mortars, or any other refractory material, we have got you covered. Our team of experts is dedicated to understanding your specific requirements and recommending the most suitable products for your applications.

In addition to our wide range of products, we also provide comprehensive services such as installation, maintenance, and technical support. Our skilled technicians are trained to handle the installation of refractory materials with precision and efficiency. We understand the importance of timely execution and strive to minimize downtime for your operations.

As a subsidiary of CNBM, we have access to a vast global network of suppliers, ensuring that we can source the best quality materials at competitive prices. Our strong relationships with manufacturers enable us to negotiate favorable terms and pass on the cost savings to our customers.

Furthermore, our years of experience in the Tunisian market have allowed us to develop strong relationships with local contractors, engineers, and industry professionals. This gives us a unique advantage in understanding the market dynamics and providing valuable insights and expertise to support your projects.

At our company, we prioritize customer satisfaction and aim to exceed your expectations. We take pride in delivering high-quality products, reliable services, and excellent customer support. Whether you are in the steel, cement, glass, or any other industry requiring refractory materials, we are here to fulfill all your needs.

Contact us today to discuss your refractory materials requirements in Tunisia and let us provide you with the best solutions tailored to your specific needs.

In addition to our wide range of products, we also provide comprehensive services such as installation, maintenance, and technical support. Our skilled technicians are trained to handle the installation of refractory materials with precision and efficiency. We understand the importance of timely execution and strive to minimize downtime for your operations.

As a subsidiary of CNBM, we have access to a vast global network of suppliers, ensuring that we can source the best quality materials at competitive prices. Our strong relationships with manufacturers enable us to negotiate favorable terms and pass on the cost savings to our customers.

Furthermore, our years of experience in the Tunisian market have allowed us to develop strong relationships with local contractors, engineers, and industry professionals. This gives us a unique advantage in understanding the market dynamics and providing valuable insights and expertise to support your projects.

At our company, we prioritize customer satisfaction and aim to exceed your expectations. We take pride in delivering high-quality products, reliable services, and excellent customer support. Whether you are in the steel, cement, glass, or any other industry requiring refractory materials, we are here to fulfill all your needs.

Contact us today to discuss your refractory materials requirements in Tunisia and let us provide you with the best solutions tailored to your specific needs.

Hot Search

- Monolithic Refractories in Malawi

- Ceramic Fiber Products in Niue

- Refractory Bricks in Dominica

- Raw Materials For Refractory in India

- Refractory Bricks in Botswana

- Ceramic Fiber Products in Papua New Guinea

- Ceramic Fiber Products in Samoa

- Monolithic Refractories in Poland

- Raw Materials For Refractory in Ireland

- Monolithic Refractories in Nauru