All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

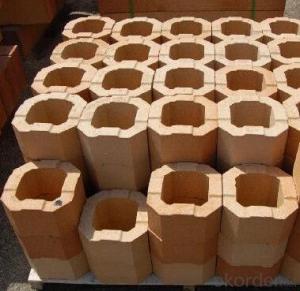

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the common refractory brick shapes used in steel ladles?

The common refractory brick shapes used in steel ladles include straight bricks, arch bricks, bottom bricks, and safety bricks.

Can refractory bricks be used in contact with acetic acid?

No, refractory bricks cannot be used in contact with acetic acid as it can react with the material and cause deterioration or corrosion.

What are the different methods of installing refractory bricks?

There are several methods of installing refractory bricks, including dry stacking, plastic refractory installation, gunning, and casting. Dry stacking involves placing the bricks on top of each other without any bonding material. Plastic refractory installation involves mixing the refractory material with water to create a plastic-like consistency, which is then used to bond the bricks together. Gunning is a method where a high-velocity stream of refractory material is sprayed onto the surface, creating a dense and strong layer. Casting involves pouring a refractory mixture into a mold or formwork, allowing it to solidify and form the desired shape.

Wholesale Refractory Bricks from supplier in Tunisia

Whether you are in need of high-quality Refractory Bricks for industrial or construction purposes in Tunisia, our company is here to meet your needs. As a subsidiary of CNBM, a renowned Fortune Global 500 company, we have the resources and expertise to provide you with top-notch products and services.

Our comprehensive range of Refractory Bricks includes various types such as fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and insulating bricks. We understand that different projects require different specifications, so we offer a diverse selection to cater to your specific requirements.

In addition to supplying Refractory Bricks, we also provide a range of services to streamline your procurement process. Our team is dedicated to offering exceptional customer service, from assisting you with sales and quotations to providing technical support. We aim to make your experience as seamless and hassle-free as possible.

With our extensive experience in the Tunisian market, we have developed a deep understanding of the local industry and its unique challenges. This allows us to offer invaluable insights and expertise to help you make informed decisions for your projects. Whether you are constructing a new facility or carrying out maintenance work, we can provide tailored solutions to meet your needs.

By choosing us as your supplier of Refractory Bricks in Tunisia, you can benefit from our one-stop solution. We have a wide range of products, excellent customer service, and the backing of a global company, ensuring that all your requirements are met efficiently and effectively.

Contact us today to explore our diverse range of Refractory Bricks and take advantage of our expertise and comprehensive services for all your Tunisia-based projects.

Our comprehensive range of Refractory Bricks includes various types such as fire clay bricks, high alumina bricks, silica bricks, magnesia bricks, and insulating bricks. We understand that different projects require different specifications, so we offer a diverse selection to cater to your specific requirements.

In addition to supplying Refractory Bricks, we also provide a range of services to streamline your procurement process. Our team is dedicated to offering exceptional customer service, from assisting you with sales and quotations to providing technical support. We aim to make your experience as seamless and hassle-free as possible.

With our extensive experience in the Tunisian market, we have developed a deep understanding of the local industry and its unique challenges. This allows us to offer invaluable insights and expertise to help you make informed decisions for your projects. Whether you are constructing a new facility or carrying out maintenance work, we can provide tailored solutions to meet your needs.

By choosing us as your supplier of Refractory Bricks in Tunisia, you can benefit from our one-stop solution. We have a wide range of products, excellent customer service, and the backing of a global company, ensuring that all your requirements are met efficiently and effectively.

Contact us today to explore our diverse range of Refractory Bricks and take advantage of our expertise and comprehensive services for all your Tunisia-based projects.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Afghanistan

- Refractory Bricks in Lebanon

- Raw Materials For Refractory in Mozambique

- Refractory Bricks in Bahrain

- Refractory Bricks in Guinea

- Raw Materials For Refractory in Greece

- Raw Materials For Refractory in South Africa

- Refractory Bricks in Moldova

- Monolithic Refractories in Guinea Bissau