Metal Roof Panels Prepainted Steel Sheet /Zinc Coating GI GL Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Metal Roof Panels Prepainted Steel Sheet /Zinc Coating GI GL Steel

1.Application

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

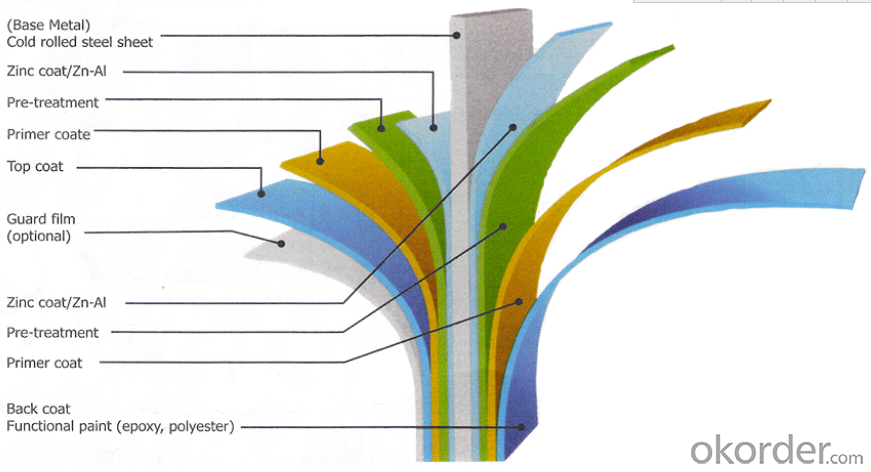

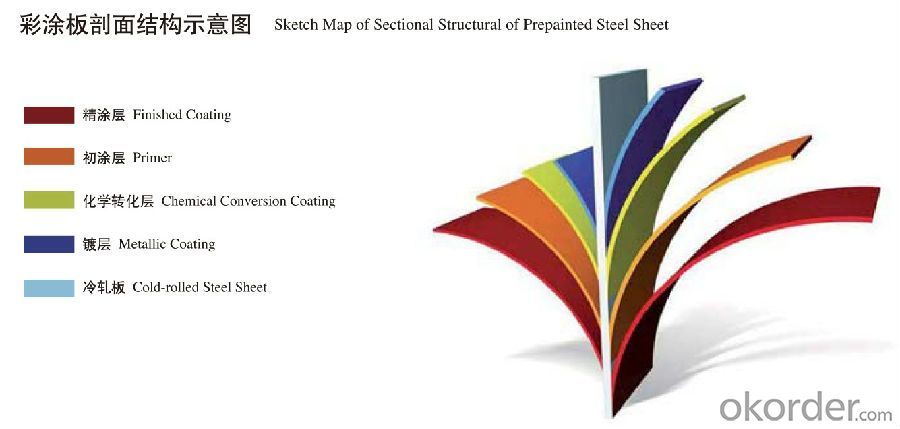

2.Features

With excellent cold-rolling steel strips as base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Product Details

Base Material | Metal Roof Panels Prepainted Steel Sheet |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

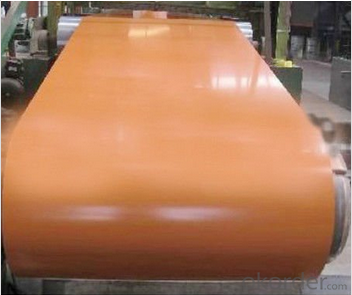

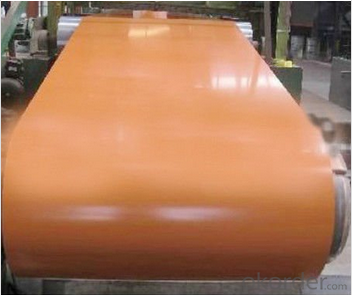

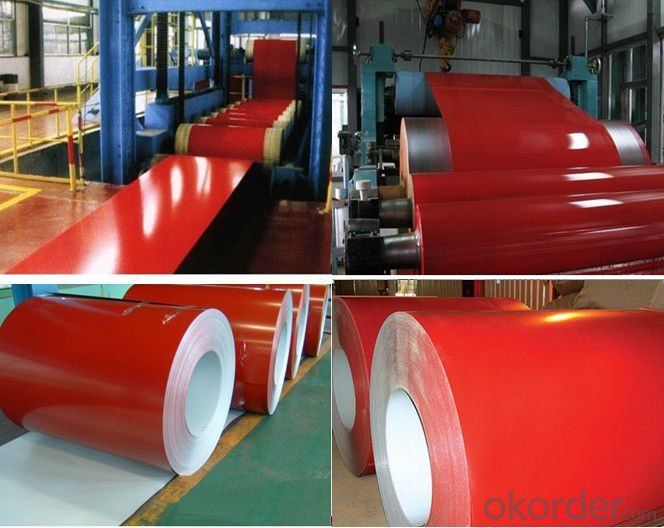

4. Image:

Production

Production Line

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: So what's harder gold or steel

- steel. gold is pretty soft.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are commonly used in the production of oil and gas machinery for various purposes. They are utilized in the manufacturing of pipes, tanks, and pressure vessels, providing structural strength and durability to withstand the harsh conditions of oil and gas operations. Additionally, steel coils are shaped and formed into components such as valves, fittings, and flanges, which are crucial for the proper functioning of the machinery. Overall, steel coils play a vital role in ensuring the reliability and efficiency of oil and gas machinery.

- Q: How are steel coils used in the production of industrial storage tanks?

- Industrial storage tanks commonly utilize steel coils due to their superior strength and durability. These coils are typically crafted from high-quality steel that is rolled into a coil shape, enabling convenient transportation and handling. During the production process, steel coils are initially uncoiled and flattened to create steel sheets. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are joined together through welding or bolting to construct the tank's body, which is designed to endure high pressure and heavy loads. The utilization of steel coils in the production of industrial storage tanks offers numerous benefits. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and resist corrosion. This is particularly vital for storage tanks containing corrosive substances or exposed to severe environments. Moreover, the flexibility of steel coils permits customization of the tank's design and size. This is especially advantageous in industries with varying storage requirements, like the oil and gas sector. Steel coils can be effortlessly cut and molded into diverse shapes and sizes, facilitating the creation of storage tanks tailored to specific storage needs. Furthermore, steel coils are easily transportable and storable, making them a cost-effective choice for industrial storage tank production. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. In conclusion, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their usage guarantees the safe storage and protection of various substances, rendering them indispensable in a wide range of industries.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- That barrel cost 150 dollars for a reason. They are god made to withstand these kind of shots.

- Q: At what temperature does steel start to warp or soften.

- Steel will only warp due to temperature under two conditions: 1. It is not heated evenly - in this case, the hotter parts will expand more than the cooler parts. 2. There are internal stresses in the steel (often from welding or cold-working - as an example, an I-beam or C-channel is usually hot worked, but some cold work can happen, so they can sometimes warp if you heat them ). This means that the steel won't warp due to temp if it's not 1 or 2. However, it could soften and fail if it has a load on it. As for softening, it really depends on what steel alloy you're looking at. Some steels (mainly the expensive alloys) don't really change until above 400 C (750 F), but mild steel really starts to weaken around 150-200 C (300-400 F) Rajashekhar has a point when it comes to forging. Steel isn't really soft enough to forge properly until above 1000C (1830 F), but if you're worried about using steel in a higher temp situation (like around a blast furnace or industrial oven), then make sure you choose a steel that has been rated to work at that temp.

- Q: Can anyone please tell me what is the DUCTILE TO BRITTLE TRANSITION TEMPERATURE IN STEEL LOW CARBON?Thanks.

- whilst metallic generators make it the technique is watched interior sight the aggregate warmth, Time in the previous the pour. some steels are run in vegetation that mixture in basic terms for solid demanding product. maximum any simple metallic may be greater effective in its hardness via heating and dipping into oils or water then do it over many cases.To make your question undeniable all metallic is simple except they technique it to be greater good or that's hardened via a warmth treating technique at a later date.

- Q: What are the common problems faced during steel coil production?

- There are several common problems that can be encountered during steel coil production. One of the most common issues is coil breakage or damage. This can occur due to improper handling or transportation of the coils, which can lead to cracks or fractures. It is crucial to ensure proper handling procedures are followed to minimize the risk of coil breakage. Another common problem is coil slippage. This occurs when the coils are not securely stacked or stored, leading to them shifting or sliding. Coil slippage can result in damage to the coils and potentially cause accidents or injuries. Therefore, it is essential to have proper storage systems in place to prevent coil slippage. Additionally, coil corrosion is a common problem faced during steel coil production. Corrosion can occur due to exposure to moisture, air, or other corrosive substances. It can lead to the degradation of the steel, reducing its strength and durability. Implementing effective corrosion prevention measures, such as proper coating or storage techniques, is essential to mitigate this issue. Another challenge in steel coil production is coil quality issues. This can include inconsistent thickness, width, or surface defects on the coils. These quality problems can arise due to various factors, such as improper rolling processes, equipment malfunctions, or material defects. Regular quality checks and inspections should be conducted to identify and address any issues promptly. Moreover, coil handling and loading problems can also occur during steel coil production. Improper lifting or loading techniques can cause damage to the coils, leading to deformations or even accidents. It is crucial to train and educate employees on proper handling and loading procedures to prevent such problems. Overall, steel coil production can face various challenges, from coil breakage and slippage to corrosion and quality issues. Implementing proper handling, storage, and quality control measures is essential to minimize these problems and ensure the production of high-quality steel coils.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These grades are selected based on the specific requirements and application of the coils, such as strength, corrosion resistance, and formability.

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

Send your message to us

Metal Roof Panels Prepainted Steel Sheet /Zinc Coating GI GL Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords