Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Application of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

Construction.

The manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

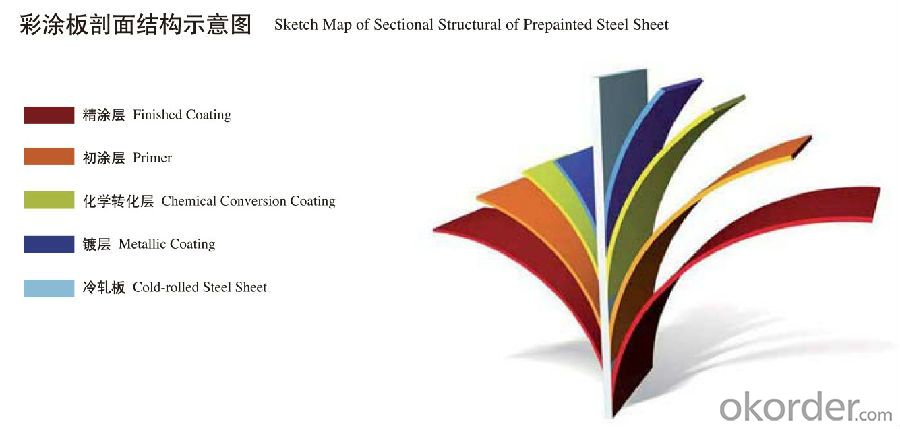

2.Features of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

4. Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating image:

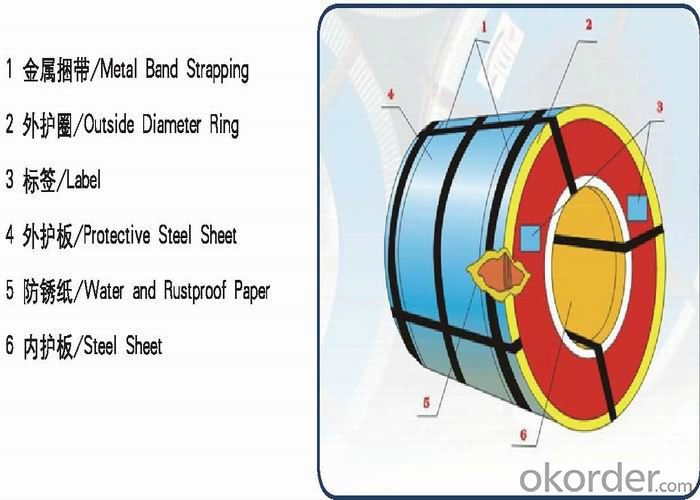

5.Packaging:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves subjecting a small sample of the steel coil to a controlled force, measuring the amount of force required to deform or break the material. Hardness testing determines the resistance of the steel to indentation or scratching, providing insights into its strength and durability. Impact testing assesses the ability of the steel to withstand sudden loads or shocks by striking a sample with a pendulum and measuring the energy absorbed during fracture. These tests help evaluate the quality and suitability of steel coils for specific applications.

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- if you are a good player they say steel shaft is better. more consistent. I prefer graphite its lighter and I can flip my wrists easier.

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are a vital element in the manufacturing of storage shelves. Typically composed of carbon steel, these coils undergo various processes to achieve the desired form. To begin using steel coils for storage shelves, the coil must be unrolled and flattened. This operation is executed by a decoiler machine, which unwinds the coil and guides it through a series of rollers to flatten the metal. Once the coil is flattened, it is prepared for further processing. Following this, the flattened steel is cut into specific lengths using either a shearing machine or a saw. These cut pieces are then bent and shaped to fit the appropriate dimensions required for the storage shelves. The bending process is typically carried out using a press brake or a roll former, which applies pressure to the metal to achieve the desired shape. Once the steel has been shaped to the correct dimensions, it is welded together to form the structure of the storage shelf. This welding procedure guarantees the strength and durability of the shelves, enabling them to support heavy loads. Upon completion of the welding process, the storage shelves may undergo additional treatments to enhance their appearance and protect them against corrosion. These treatments can include processes like powder coating, galvanization, or painting. In summary, steel coils play an indispensable role in the production of storage shelves. They provide the essential raw material and their versatility allows for a wide range of shapes and sizes to be created. The strength and durability of steel make it the ideal choice for storage shelves, ensuring that they can endure heavy loads and provide long-lasting storage solutions.

- Q: I own a crappy steel string acoustic and a very nice electric guitar.I have saved up to buy a new acoustic but I cannot decide to just invest in a better steel string or explore around with a nylon string. From others experience, will I get my fill of satisfaction of playing on a nylon, or should I stick to a steel string?

- Nylon string guitars are mostly classical guitars ment for classical and flamenco music, both guitars, nylon and steel, sound really well. My dad has a steel acoustic and I have a nylon classical guitar by Cordova It just depends on what style of music you play. When your buying a new guitar, play as many guitars to try them out once you find what you which one you want, you'll know

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry.

- Q: so I am trying to drill holes in stainless steel shelving to hang something but my drill wont make any more than a small dent in the steel. I bought a bit for hard metals but it didn't do any better. I have an admittedly small drill (9.6v). is that the problem? do I just need a more powerful drill? any serious advice is appreciated. thanks

- As long as it turns the bit, the power, (torque), at the drill is not a factor. 1. The bit you have is probably ruined by overheating. replace it. (See 3. below). 2. Do use water or cutting oil to cool your drill bit. 3. If you're drilling more than a very small hole, start with a small pilot bit to make the first hole, then follow with the larger full size bit.

- Q: steel bollard poles?

- They're short steel posts that are used as a barrier to keep traffic out of an area. If you want to see an example Google it and look at the pics.

- Q: I understand that Stainless Steel is a low carbon steel having minimum 10.5% chromium content in it there r 60 different type of stainless steel. Kindly informa) Is this info correct?????b) Which stainless steel can get rusted or can have superficial rust????

- Stainless steel is a generic term for a whole range (there are more than 60 types) of Fe-Cr alloys. They all contain some amount of C and some alloys include a good number of other alloying elements. In almost all cases, the materials have corrosion resistance due the Cr atoms that are in solid solution with the Fe matrix. Under corrosive conditions, the Cr forms a thin tight coherent layer of Cr-oxide. This Cr oxide coating prevents further corrosion so long as it is not chemically or physically removed. If the SS has been subject to mechanical abrasion, the corrosion resistance can sometimes be restored by a light exposure to nitric acid which passivates the surface, restoring the Cr-oxide layer. The carbon content is an important factor in corrosion preformance but so is the heat treatment. Under the wrong conditions and in different environments, all SSs can rust. One of the most common corrosion problems is sensitization which occurs in the heat affect zone (HAZ) around welds. If the C content is high enough and the heat is high enough, the Cr atoms in solid solution form Cr-carbides and are no longer available to form a protective Cr-oxide. The corrosion resistance can be restored by appropriate heat treatment.

- Q: How can I owe a Pre-engineered Steel Building?

- You just have to do small efforts for owing a steel building: Firstly you have to finalize a steel building company for construction work. After finalizing the steel building company, the next step is the paperwork - the agreements and contracts. Some steel building companies may also ask for a verbal approval for the factories to get the work started.

Send your message to us

Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords