Max Loading Capacity 10T Tower crane TC6024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

Type hammer head

Max loading capacity: 10T

Tip loading:2.4t

Jib length:60m

Free standing height:50m

Mast section: 2mx2mx3m

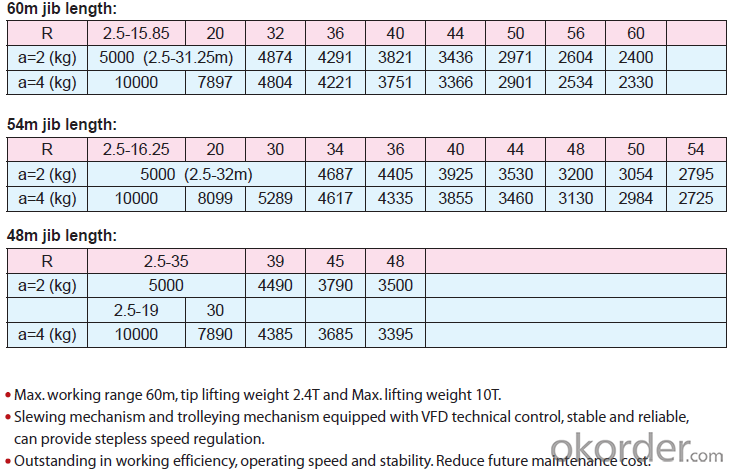

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: Who do you think would win in a battle between Roger Thorpe and Alistair Crane?

- HI! I didn't know there was another character named Roger Thorpe. I remember a character named Roger Thorpe on the Guiding Light years ago.

- Q: Only two magnification and four magnification are seen in the data, and the difference in weight is 0.1T. 10How does this magnification change during construction? Do you know that the door crane is changing the grab tower?

- Magnification, in simple terms, refers to several ropes through the hookIf it is one in and out of two wire rope, that is two magnificationSimilarly, two into two out is four magnification

- Q: When the earthquake happened, the children wanted to know what they could do to inform other students and raise awareness for the people in Japan. So, we decided to do a show on the earthquake, and to also making the cranes, the origami cranes.thank you! a foreigner. (detail)

- To also make the cranes is the correct way to say it. To also making the cranes is incorrect.

- Q: Like the tall cranes on construction sites. I mean, suddenly they're just magically there!

- so trueee!

- Q: What are the types of common tower cranes?

- (3) according to erection methodNon self erecting tower crane: a tower crane assembled and erected by other lifting equipment.Self erecting tower crane: a tower crane that relies on its own power unit and mechanism to realize the transition between the transportation state and the working state.(4) according to variable amplitude methodThe trolley jib tower crane lifting trolley along the tower crane luffing boom for operation.Boom luffing tower crane: luffing tower luffing luffing luffing crane.Folding tower crane: tower crane which can be bent by boom according to the needs of lifting operation. It can also have the performance of luffing and luffing.

- Q: inventor of junk yard electromagnetic crane?

- Who Invented The Electromagnet

- Q: Lifting tower crane tower more than 45 meters, the demolition cost and how to adjust the field Sinotrans transportation fees?

- Self lifting tower crane tower 45 meters high to prevail, such as height of over 45 meters, each increased to 10 meters (less than 5 meters, excluding) demolition costs increase 20%, off-site transportation costs increased by 10%.

- Q: I was looking at the glidecam hd1000 for my canon vixia hv40, but now I think I'm more interested in a crane (jib).I was thinking of the advance digital 6 ft. crane. I would replace some of the plastic parts for metal.I'll be using it to film sketches and short films. (my budget is 350 dollars, but id like it to be under that)the crane is 200 dollarsthe glidecam is 370 dollars (on amazon)Thanks,Mike

- Yeah corner of foremost and Higgins. Just isn't all love bought at one time or one other. We have now the love that may be purchased on the street however even in eveyday existence is just not love purchased by means of gifts, dinner, it will not be what we call soiled love however it's still purchased. Wheather it can be a man shopping for a woman or lady for man. Take care dave PS nothing is free.

- Q: What is the wall radius of a qtz50 tower crane?

- The working radius is usually 50 meters. There are also 48, 49 meters. For example, 4810, 4910, and 5010, belong to 50 tons of tower cranes.Qtz50 resolves to:Q: crane;T: Tower type;Z: Jack up;50: lifting torque of 50 tons meters.

- Q: any one can give me address for forged hook for crane?

- here okorder /

Send your message to us

Max Loading Capacity 10T Tower crane TC6024

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords