Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM23

Insulating fire bricks GJM23 are made from high purity alumina and low iron content raw materials. The insulating fire bricks are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1260℃(2300℉). A variety of type could be done according to customer’s request.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM23,we choose the casting methord.The casting insulating fire bricks offering the lowest density, the lowest thermal conductivity for the application above 1000℃.

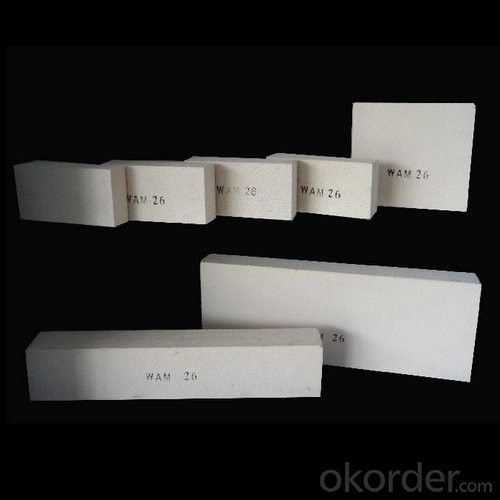

General Information of Insulating Fire Brick GJM26

Insulating fire brick GJM26 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM26,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM28

Insulating fire brick GJM28 are produced by high purity alumina and low iron raw materials. A viariety of shapes are available.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM28,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM30

Insulating fire brick GJM30 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM30 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM30,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Typical Application of Insulating Fire Brick

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick

| JM23 | JM26 | JM28 | JM30 | JM32 | ||||

| Physical Properties: | ||||||||

| Classifiction Temperature | ℃ | 1260.0 | 1430.0 | 1500.0 | 1600.0 | 1650 | ||

| Density | Kg/m3 | 550.0 | 850.0 | 900.0 | 1000.0 | 1100 | ||

| Cold Crushing Strength | Mpa | 1.2 | 2.0 | 2.5 | 2.8 | 3.5 | ||

| Reheating Linear Change(24hrs) | ||||||||

| 1230℃ | % | 0.4 | ||||||

| 1300℃ | ||||||||

| 1400℃ | % | 0.5 | ||||||

| 1510℃ | % | 0.6 | ||||||

| 1600℃ | % | 0.7 | ||||||

| 1650℃ | % | 0.8 | ||||||

| Hot Load Strength Deform(90 minutes) | ||||||||

| 1100℃ at 0.034 Mpa(5psi) | % | 0.1 | ||||||

| 1260℃ at 0.069 Mpa(10psi) | % | 0.2 | ||||||

| 1320℃ at 0.069 Mpa(10psi) | % | 0.3 | ||||||

| 1370℃ at 0.069 Mpa(10psi) | % | 0.2 | 0.1 | |||||

| Thermal Conductivity | ||||||||

| 400℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.32 | ||

| 600℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.35 | ||

| 800℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.38 | ||

| 1000℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.42 | ||

| 1200℃ | W/m.k | 0.4 | 0.4 | 0.4 | 0.44 | |||

| 1400℃ | W/m.k | |||||||

| Specific Heat | KJ/Kg.K | 1.1 | 1.1 | 1.1 | 1.1 | 1.10 | ||

| Chemical Analysis: | ||||||||

| Al2O3 | % | 47.0 | 50.0 | 60.0 | 70.0 | 75.0 | ||

| SiO2 | % | 44.4 | 47.1 | 38.2 | 28.3 | 23.2 | ||

| Fe2O3 | % | 0.9 | 0.7 | 0.6 | 0.5 | 0.5 | ||

| TiO2 | % | 1.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| CaO | % | 5.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| MgO | % | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | ||

| Na2O+K2O | % | 1.1 | 1.7 | 0.8 | 0.7 | 0.6 | ||

Photo of Insulating Fire Brick

- Q: Can insulating fire bricks be cut to custom sizes?

- Yes, insulating fire bricks can be cut to custom sizes. These bricks are made from lightweight materials such as ceramic fibers, which make them easier to shape and cut according to specific requirements.

- Q: Do insulating fire bricks have a high resistance to spalling?

- Yes, insulating fire bricks have a high resistance to spalling.

- Q: Is sintering insulation brick good or concrete porous brick good?

- As with the expansion screw, it depends on what to connect, and go in is no problem, the key is that the carrying capacity is not very high, if you do steel support, pull and so on, it is recommended to use concrete.

- Q: Can insulating fire bricks be used as a backup insulation in refractory linings?

- Yes, insulating fire bricks can be used as a backup insulation in refractory linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them effective in reducing heat transfer in high-temperature applications. Their insulating properties make them ideal for use as a backup insulation layer in refractory linings, helping to further reduce heat loss and improve overall energy efficiency. Additionally, insulating fire bricks are lightweight, which makes them easier to handle and install compared to other refractory materials. However, it is important to consider the specific requirements of the application and consult with a refractory engineer to ensure that insulating fire bricks are suitable for the specific conditions and performance requirements of the refractory lining.

- Q: Are insulating fire bricks suitable for use in glass furnaces?

- Indeed, glass furnaces can benefit from the use of insulating fire bricks. The purpose of these bricks is to possess a low thermal conductivity, thereby effectively insulating the soaring temperatures within the furnace. By minimizing heat loss, these bricks ensure a steady temperature is maintained inside the furnace, a vital factor in the glass-making process. Moreover, insulating fire bricks are capable of enduring the intense temperatures and thermal shocks typically experienced in glass furnaces. Additionally, their lightweight nature facilitates simple installation and maintenance procedures. In conclusion, insulating fire bricks prove to be a dependable and pragmatic option for utilization in glass furnaces.

- Q: Are insulating fire bricks resistant to thermal expansion or contraction?

- Indeed, insulating fire bricks exhibit a remarkable resistance to thermal expansion and contraction. These bricks are composed of materials possessing minimal thermal conductivity, enabling them to endure elevated temperatures without experiencing substantial expansion or contraction. This characteristic renders them exceptionally well-suited for scenarios necessitating thermal stability and insulation, including kilns, furnaces, and various high-temperature settings.

- Q: Do insulating fire bricks have a high resistance to creep?

- Yes, insulating fire bricks generally have a high resistance to creep. The low thermal conductivity and high refractoriness of these bricks allow them to withstand high temperatures without significant deformation or creep.

- Q: Do insulating fire bricks require any special installation techniques?

- Special installation techniques are necessary for insulating fire bricks. These bricks are designed to offer excellent thermal insulation, so proper installation is essential for optimal performance. To begin, it is crucial to have a clean and debris-free installation surface. This creates a strong and stable foundation for the bricks. Afterward, it is important to use a suitable refractory mortar or adhesive to secure the bricks in place. This mortar should be specifically designed for high-temperature applications and capable of withstanding thermal expansion and contraction during heating and cooling cycles. During installation, attention should be given to filling the joints between the bricks with mortar. This prevents heat loss and maintains the insulating properties of the bricks. Furthermore, careful stacking and alignment of the insulating fire bricks is necessary to ensure a tight fit and minimize gaps. This maximizes insulation and prevents heat leakage. Lastly, it is advisable to consult the manufacturer's guidelines and follow their recommended installation techniques. Different types of insulating fire bricks may have specific requirements that must be adhered to for proper installation. In summary, insulating fire bricks demand special installation techniques to ensure their effectiveness and longevity. Following proper installation practices will enhance the thermal insulation properties of these bricks and optimize their performance.

- Q: Do insulating fire bricks require any special insulation blankets or jackets?

- Insulating fire bricks (IFBs) are designed to have excellent insulating properties, so they generally do not require any special insulation blankets or jackets. However, depending on the specific application and environment, additional insulation may be needed. If the IFBs are exposed to high temperatures or extreme thermal conditions, it may be beneficial to use insulation blankets or jackets to further enhance their insulation capabilities and protect them from damage. These additional insulation materials can help reduce heat loss, increase energy efficiency, and extend the lifespan of the IFBs. Therefore, while not always necessary, it is worth considering using insulation blankets or jackets in certain situations to optimize the performance of insulating fire bricks.

- Q: Can insulating fire bricks be used for kiln furniture?

- Indeed, kiln furniture can be fashioned from insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are frequently employed in industrial kilns and furnaces. Their exceptional thermal insulation characteristics render them perfect for crafting kiln furniture like shelves, posts, and supports. The insulating attributes of these bricks aid in the uniform dispersion of heat throughout the kiln, guaranteeing consistent heating of the items being fired. Furthermore, insulating fire bricks possess a lightweight composition and are effortlessly manageable, thereby making them a convenient selection for kiln furniture.

Send your message to us

Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords