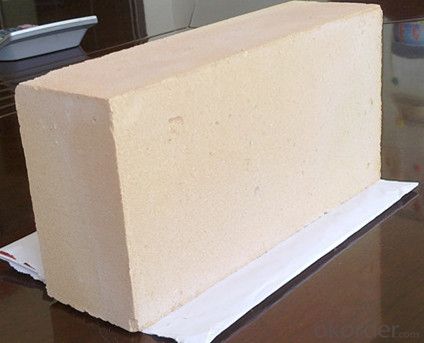

Insulating Fire Brick for Blast Furnace and Industrial Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Are insulating fire bricks resistant to erosion?

- Insulating fire bricks, in general, exhibit resistance to erosion. They consist of lightweight materials like alumina, silica, or a combination thereof. These materials possess remarkable resistance to erosion caused by elevated temperatures, chemical reactions, and physical wear. They are engineered to endure extreme heat and harsh circumstances, rendering them highly resistant to erosion. Furthermore, insulating fire bricks demonstrate low thermal conductivity, preventing easy absorption or transfer of heat and thereby affording additional protection against erosion. Nevertheless, it is worth noting that the level of erosion resistance may differ depending on the precise composition and quality of the insulating fire bricks.

- Q: Can insulating fire bricks be used in brick ovens?

- Yes, insulating fire bricks can be used in brick ovens. They are designed to withstand high temperatures and have excellent heat insulation properties, making them suitable for use in brick ovens to help retain and distribute heat evenly.

- Q: Can insulating fire bricks be used in high-temperature kilns for pottery?

- Yes, insulating fire bricks can be used in high-temperature kilns for pottery. These bricks are specifically designed to withstand and retain heat, making them suitable for use in kilns that reach high temperatures. They help to insulate the kiln, preventing heat loss and allowing for more efficient firing of pottery.

- Q: Can insulating fire bricks be used in heat treatment furnaces?

- Yes, insulating fire bricks can be used in heat treatment furnaces. Insulating fire bricks are specially designed to have low thermal conductivity, which means they are able to withstand high temperatures while minimizing heat loss. This makes them ideal for use in heat treatment furnaces, where maintaining a consistent temperature is crucial for the successful heat treatment process. Additionally, insulating fire bricks have excellent insulating properties, which helps to reduce energy consumption and improve the overall efficiency of the heat treatment furnace. Therefore, using insulating fire bricks in heat treatment furnaces is a common practice in various industries.

- Q: Are insulating fire bricks resistant to salt attack?

- Insulating fire bricks are not typically resistant to salt attack. Salt attack refers to the corrosion and degradation of materials when exposed to salt or saltwater. While insulating fire bricks are designed to have excellent thermal insulation properties, they are not specifically formulated to withstand the corrosive effects of salt. Salt attack can lead to the breakdown of the bricks' structure, reducing their performance and durability over time. If these bricks are regularly exposed to salt or saltwater, it is likely that they will experience accelerated degradation and may not provide long-term reliability in such environments. To ensure resistance to salt attack, it is recommended to use refractory materials specifically designed for this purpose, such as salt-resistant fire bricks or refractories with higher alumina content. These materials have been developed to withstand the corrosive effects of salt and are more suitable for applications where exposure to salt or saltwater is expected.

- Q: How do insulating fire bricks help improve the efficiency of heat recovery systems?

- Insulating fire bricks are essential for improving the efficiency of heat recovery systems in multiple ways. To begin with, these bricks are crafted from top-notch insulating materials like ceramic fiber, which possess exceptional thermal properties. This implies that they exhibit a low thermal conductivity, thus preventing the escape or wastage of heat. By incorporating insulating fire bricks as lining materials in heat recovery systems, the heat exchange process becomes more efficient as less heat is lost to the surroundings. Furthermore, insulating fire bricks aid in reducing heat transfer through conduction. They serve as a barrier between the hot and cold sides of the system, thereby minimizing heat loss through direct contact. This insulation effect enables the heat recovery system to maintain a higher temperature on the hot side, maximizing the temperature difference and ultimately enhancing the rate of heat transfer. In addition, these fire bricks are lightweight and possess low heat storage capabilities. Consequently, they require less energy for heating and cooling, resulting in faster response times for the heat recovery system. This quick response enables the system to adapt swiftly to changes in heat generation or demand, thereby improving its overall efficiency. Moreover, the utilization of insulating fire bricks as refractory materials in heat recovery systems aids in reducing energy consumption. Since these bricks can withstand high temperatures without cracking or deforming, they contribute to the system's longevity, reducing the need for frequent repairs or replacements. This leads to lower maintenance costs and less downtime, ultimately enhancing the overall energy efficiency of the heat recovery system. To summarize, insulating fire bricks bolster the efficiency of heat recovery systems by providing superb thermal insulation, minimizing heat loss through conduction, enabling rapid response times, and reducing energy consumption. Their incorporation as lining materials significantly enhances the heat transfer process, resulting in more effective heat recovery and utilization.

- Q: How do insulating fire bricks affect the overall durability of a structure?

- The overall durability of a structure is significantly improved with the inclusion of insulating fire bricks. These bricks are designed with a low thermal conductivity, effectively resisting heat transfer. By limiting the amount of heat that passes through, they maintain a stable temperature within the structure, safeguarding it against extreme temperature changes. One of the primary advantages of insulating fire bricks is their capacity to endure high temperatures. They possess a high melting point, enabling them to maintain their structural integrity even in the presence of intense heat. This characteristic is particularly important in structures that generate high temperatures, such as furnaces or kilns. The ability of insulating fire bricks to withstand such extreme heat greatly contributes to the structure's durability. Additionally, insulating fire bricks offer exceptional insulation. Their low thermal conductivity prevents heat from escaping or entering the structure, resulting in energy efficiency. This not only reduces energy consumption, but also shields the structure from potential damage caused by excessive heat loss. By maintaining a consistent temperature, insulating fire bricks prevent thermal expansion and contraction, which can lead to cracks and structural instability. Apart from their resistance to heat and insulation properties, insulating fire bricks are also known for their resistance to chemical corrosion. Many structures are exposed to harsh environments or chemicals that can cause deterioration. However, insulating fire bricks are made from materials that resist chemical reactions, ensuring their durability and longevity. Overall, the utilization of insulating fire bricks significantly enhances the durability of a structure. Their capacity to endure high temperatures, provide insulation, and resist chemical corrosion makes them a valuable component in various industrial and residential applications. By ensuring a stable and protected environment, insulating fire bricks contribute to the long-lasting and reliable performance of the structure.

- Q: Can insulating fire bricks be used in the construction of combustion flues?

- Yes, insulating fire bricks can be used in the construction of combustion flues. Insulating fire bricks are designed to withstand high temperatures and are often used to line combustion chambers and flues to provide insulation and prevent heat loss. They have excellent thermal properties, making them suitable for this purpose.

- Q: Can insulating fire bricks be used in blast furnaces?

- Insulating fire bricks have the capability to be utilized in blast furnaces. These bricks are specifically designed to endure high temperatures and provide exceptional thermal insulation. Blast furnaces operate under extreme temperatures, typically reaching around 1500°C (2732°F), and thus require materials that can withstand such harsh conditions. Insulating fire bricks are constructed from lightweight substances like ceramic fibers, which possess low thermal conductivity and effectively retain heat. This makes them highly suitable for lining the walls and roofs of blast furnaces as they aid in energy conservation, minimize heat loss, and enhance overall furnace efficiency. Moreover, the use of insulating fire bricks in blast furnaces also serves to safeguard the structural integrity of the furnace by reducing thermal stress and preventing excessive heat transfer to the surrounding environment. Ultimately, the incorporation of insulating fire bricks in blast furnaces contributes to enhanced performance, energy preservation, and prolonged furnace lifespan.

- Q: Can insulating fire bricks be used in paper mills?

- Insulating fire bricks are indeed applicable for use in paper mills. They are widely employed in various industries that necessitate effective insulation against elevated temperatures, including steel, glass, and ceramics. Within paper mills, where activities like drying, heating, and burning take place, insulating fire bricks offer an ideal solution for lining kilns, furnaces, and other equipment. Their exceptional thermal insulation properties and ability to withstand extreme temperatures render them highly suitable for deployment in paper mills, where heat plays an indispensable role in the manufacturing process. Furthermore, these bricks possess the advantages of being lightweight and exhibiting low thermal conductivity, enabling efficient heat retention and yielding energy savings.

Send your message to us

Insulating Fire Brick for Blast Furnace and Industrial Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords