Inorganic interior wall finishes Interior wall coatings Inorganic coatings wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 90000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

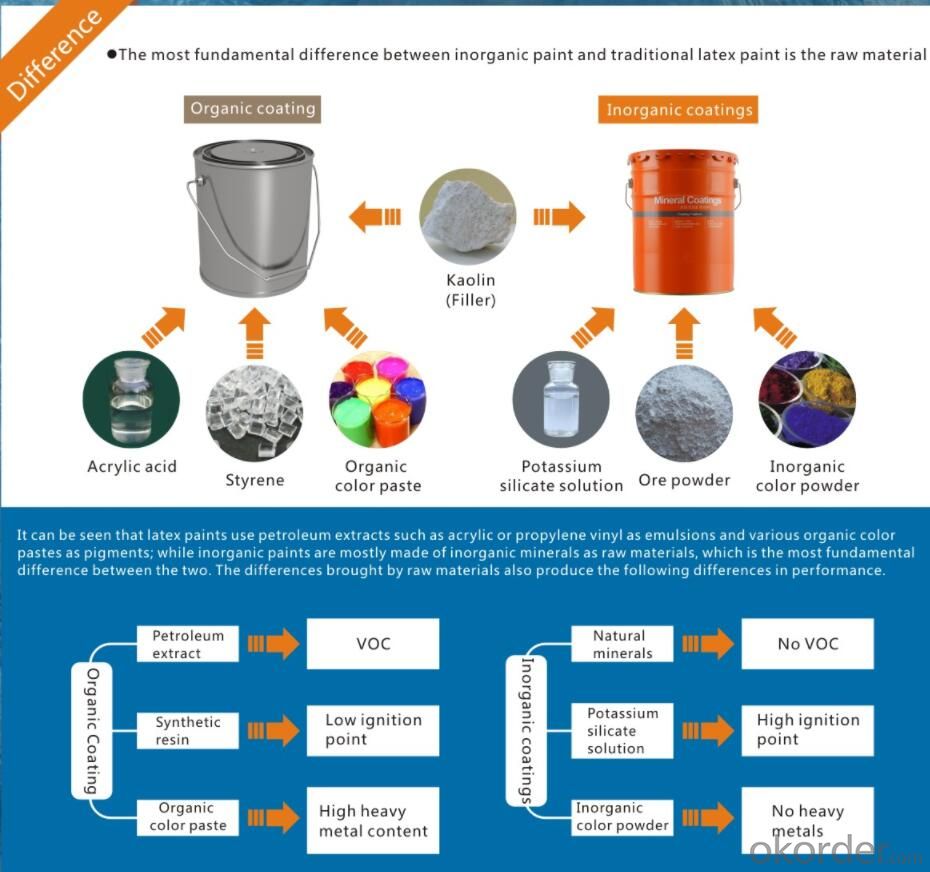

Inorganic architectural coatings for exterior walls are made by using alkali metal silicate and silica sol as the main adhesive and forming thin decorative coatings on buildings by brushing, spraying or rolling. They are developed and formulated by a professional team. They do not contain formaldehyde, volatile organic compounds, heavy metals and other harmful substances.

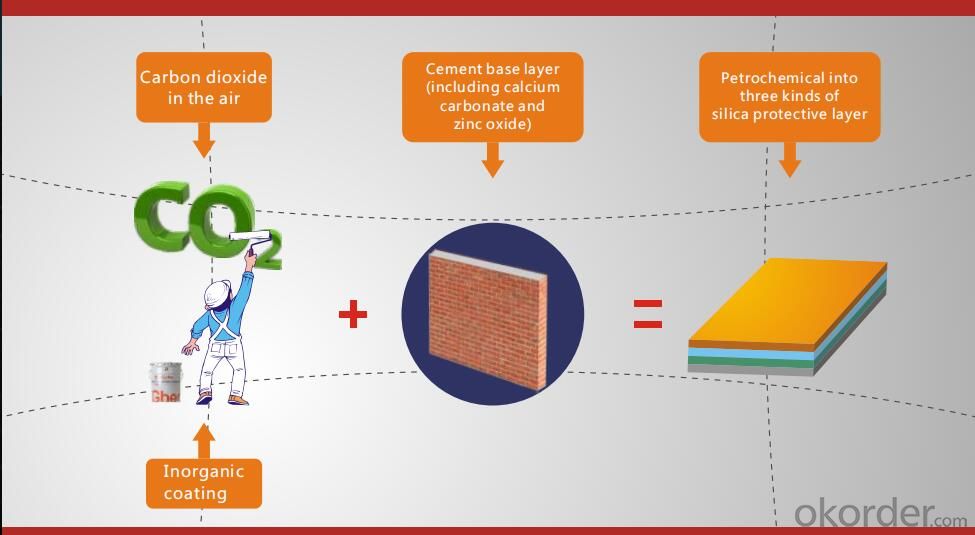

Water-based inorganic coating is a water-based architectural and decorative coating based on pure natural inorganic mineral raw materials, whose main component is oxidized modified potassium silicate and the product structure is a reticulated multi-sphere molecular combination. The inorganic components in the coating and the inorganic substances in the substrate undergo chemical reaction to form new inorganic substances, which are integrated with the substrate and not easy to fall off. The modified potassium silicate is compatible with various inorganic pigments, which not only keeps the original color but also plays a curing role and makes the coating film less likely to fade. Based on the above principles, it contributes to the natural environmental protection, fire retardant, aging resistance and super weather resistance of water-based inorganic coatings.

The reaction principle of inorganic mineral coatings

Product Characteristics:

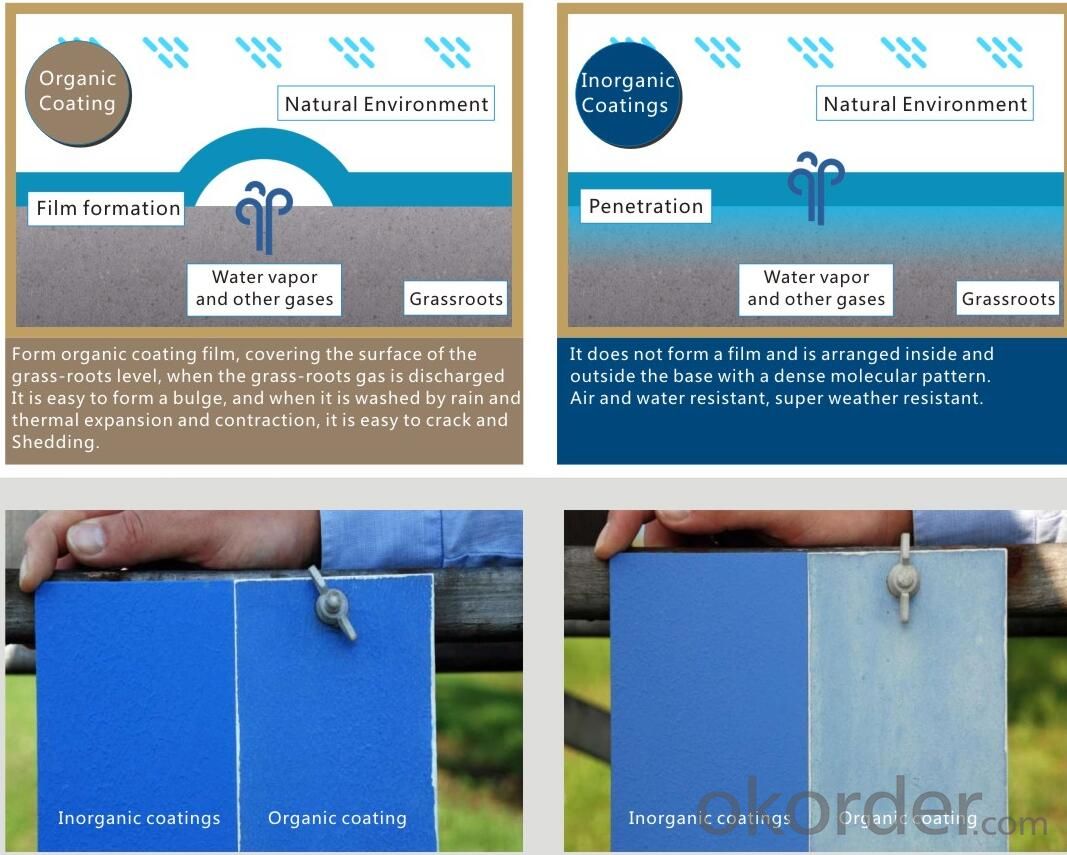

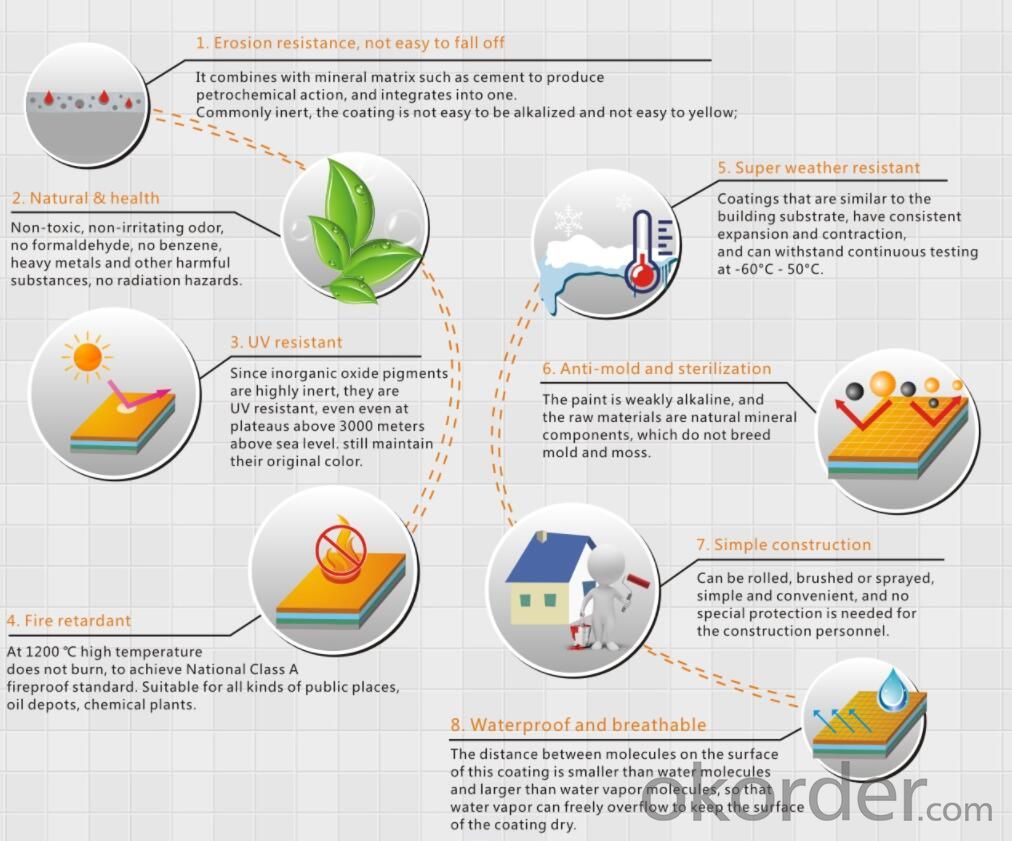

1. Inorganic coating is filled with mineral materials to form a breathable and petrification film. The film is long lasting and won't peel off so it saved any film stripping in the future maintainance. The film color is resistant to alkali or yellowing;

2. Non toxic, no pungent smell, no formaldehyde, benzene, heavy metals or other harmful substances, no radiation hazards;

3. Due to the inertia of inorganic oxide pigments, inorganic coating is UV resistant and natural color stable on the plateau of 3000 meters altitude;

4. Fire proof and flame retardancy: The coating is smoke free. The flammable point of the mineral materials used in the coating is up to 1200 ℃, qualifying for the A1 GB national standard of fire retardation. Thus the coating is suitable for all types of public places, oil depots and chemical plants where fire proof is a top concern;

5. After chemical reaction, Gber inorganic coating forms a petrification film with the substrat. The film expands and shrinks freely and can withstand the continuous test at a range of minus 60 ℃ - 50 ℃;

6. Mildew and sterilization do not breed moss. Gber inorganic mineral coating is of weakly alkaline. The raw natural mineral composition don't breed mold or moss;

7. The coating application is simple. It can be rolled, brushed or sprayed. The applicator doesn't require special protection at the construction sites;

8. Inorganic coating is waterproof and breathable. It is not easy to crack or blister. The coating depots and penetrates into the wall and forms a common layer. The film surface matrix is smaller than that of the water molecules and greater than that of water vapor. So the film has the same one-way breathing performance as that of human skin: the water vapor can breath freely to keep the coating surface dry but water won't penetrate the film.

Product Research & Development Laboratory:

The company is a comprehensive high-tech enterprise integrating scientific research, production, sales and technical services, and it is one of the leading enterprises in the production of inorganic coatings in China. The company has independent research and development team, participate in the formulation of inorganic paint industry standards, both production scale and market share are in the forefront of the country. Factory workshop has an annual output of tens of thousands of tons of water inorganic mineral coating production line, and supporting research and development testing center, office conference room, staff rooms, etc, the factory through the third party environmental impact assessment, advanced manufacturing equipment machine, perfect living facilities, the factory production environment, or enterprise staff living environment, has reached the relevant national and local government of environmental protection, energy conservation and safety regulations and standards.

With the enhancement of consumer environmental protection and health concept, the development of environmental protection of inorganic paint products will become the development trend of China and even the world paint industry.

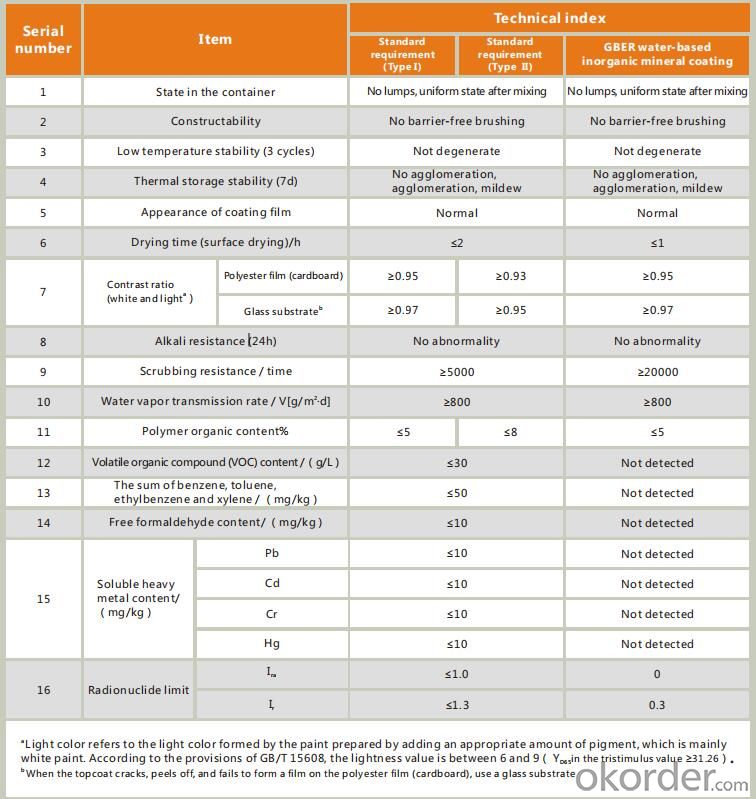

Product Specifications and Parameters:

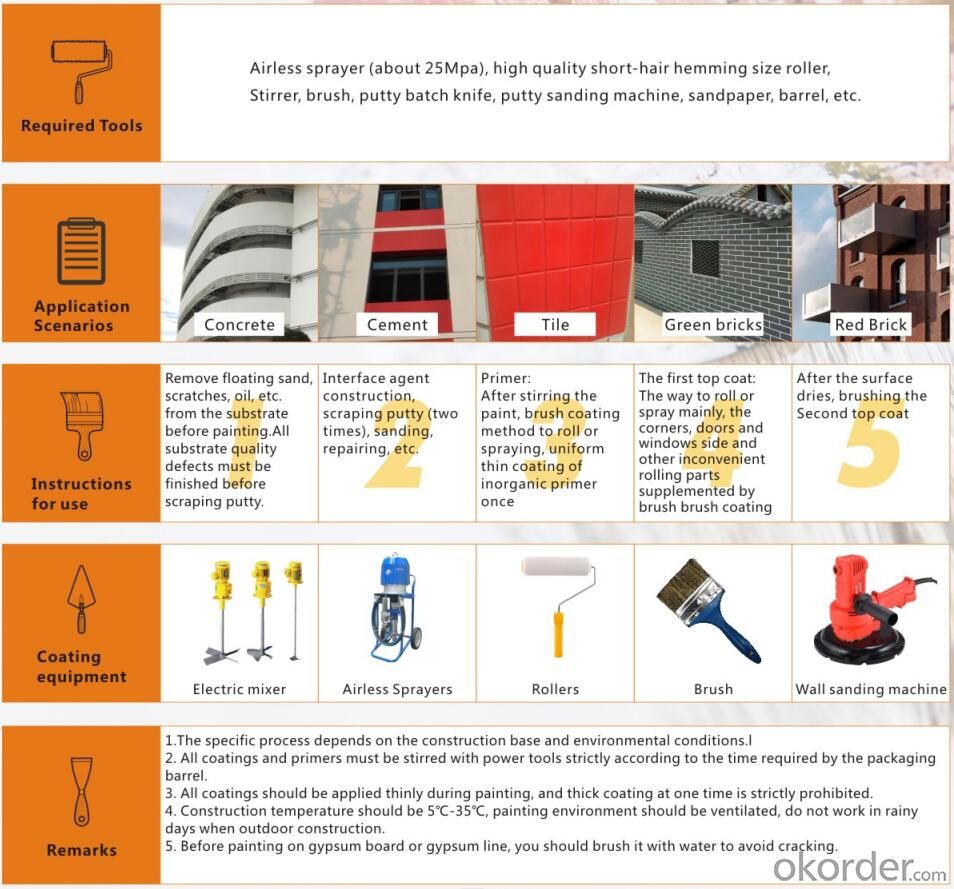

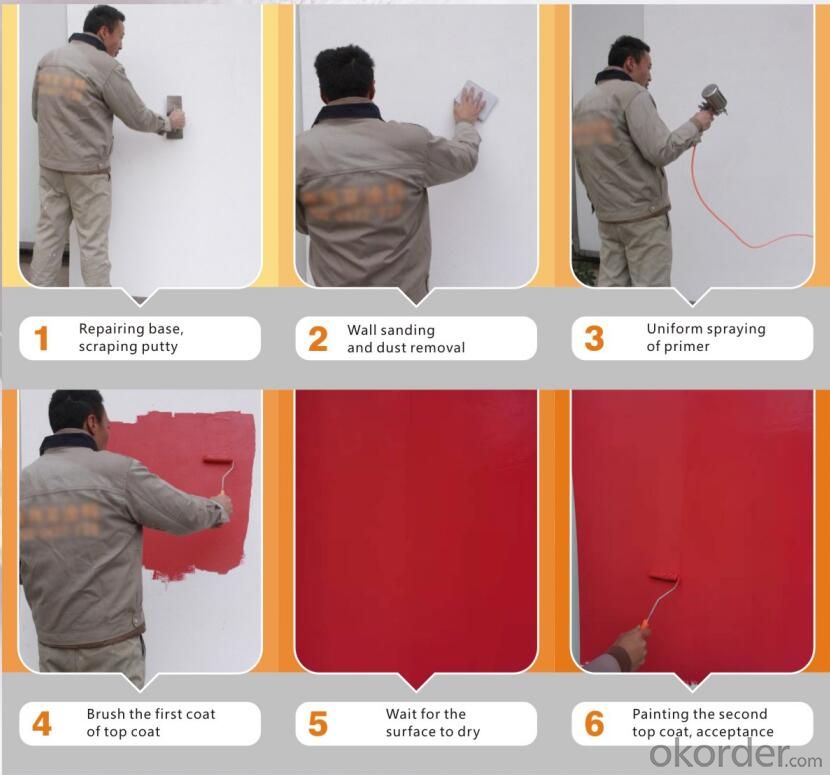

Product construction steps:

Product application cases:

FAQ:

Q1 What is the environment for inorganic coatings?

A1 Suitable for a wide range of climatic conditions, excellent protection, long service life and non-aging and non-peeling.

Q2 What is the fire resistance of inorganic coatings?

A2 inorganic coatings can achieve A1 level fire protection, will not burn in the event of fire or fire, and have certain flame retardancy and will not produce any toxic and harmful gases

Q3 Why is inorganic paint green and healthy?

A3 Non-toxic and no pungent odor, does not contain methyl awakening, benzene, heavy metals and other harmful substances, no radiation hazards

- Q: Good dye clothes will not fade?

- Whether the dyes are faded or not carcinogenic, and disperse dyes are also carcinogenic.

- Q: What is high performance polymer?

- High-performance polymer thermal stability, high melting point, can be used at 300 ℃ long-term.

- Q: I would like to ask the watercolor paint and Chinese painting which poison is bigger? Thank you

- Watercolor pigment poison ah

- Q: What are the characteristics of the polymer melt flow?

- Pseudoplastic fluid, the vast majority of polymer fluid is this type, the temperature increases, the shear increases, the viscosity decreases

- Q: Is the water-based dyes with pigments, or oily have dyes with pigments, or have ah, get me very confused

- The problem remains the same, it is recommended to reinstall the driver or replace the computer.

- Q: How do I tell if the ink is a dye ink or a color ink?

- Drip into the water, the immediate dispersion is the color of ink, and vice versa is the fuel ink

- Q: What is modified epoxy polymer mortar

- The theoretical difference in effect: 1) Adhesion of the single component is significantly lower 2) Polymer mortar strength Single component low

- Q: Apple 5s cell phone battery is lithium battery or lithium polymer battery? Friends who know ah

- The new battery to go through 3-5 times the charge and discharge can activate the battery

- Q: Who knows that the coating on the aluminum plate from the role of anti-oxidation and corrosion resistance of the kind of water-based paint is the kind of paint? Where there is a recipe to sell the best I can produce their own! Please give pointers

- Commonly used polyester coatings and fluorocarbon coatings

- Q: Interior decoration emulsion paint and color paint that cheaper

- I heard that Lu Liangwei endorsement of the brand is also good Oh!

Send your message to us

Inorganic interior wall finishes Interior wall coatings Inorganic coatings wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 90000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches