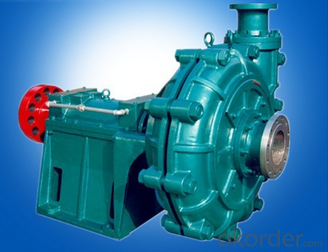

HZJ Series Heavy Duty Slurry Pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

Conform tp ISO2858, ISO5199, API682 standard

Max operating pressure 2.5Mpa

Range of capacity 4~3240m3/h

Total head 7~115m

Range of operating temperature -20~180oC

Max particle diameters 3~115mm

Max solid content 60%

2. Application

It is used to convey high-concentrated corrosive slurry containing a great deal of solid materials.

3. Materials

For wetted parts in contact with medium, the common materials are as followings,

MCU, DTM, M-3, and Cr15Mo3.

4. Pump Seal

171C, 171CL mechanical seal

Dynamic seal

5. FAQ

1 How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2 Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3 Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

- Q: My friends car is a 1997 jeep wrangler. The belt broke and she took it in to get it replaced and they told her metal from the pully that broke got into the water pumpand they have to replace that to? WTF? it makes a squealing noise and they want to charge her another 300 for that! we just don't understand how that could be if the pump isn't even leaking?

- Well like someone else has mentioned the squealing usually comes from the round pulley that the belt rides on maybe in your case some metal has damaged the idler puller on your water pump and that would definitely give you a consent squeal. the price to replace your water pump is very excessive the part at any over the counter parts store ranges from 30-45 dollars the labor too do this on a jeep is 2.2 hrs @ the shops hourly rate which also varies but 45-55 hour isn't unreasonable... so on the high side of these figures it should be about 120.00labor 45.00 parts so a bill of $165.00 would be more appropriate......but if you don't make the repairs knowing it still has a problem you might void any type of repair warranty on your current repairs already completed...hopefully this has helped you somewhat...jimboz

- Q: Does the water pump pump the coolant into the engine or pump it out?

- The automobile water pump pumps the coolant into the engineThe effect of the water pump is used for cooling the engine; it is the coolant pump in the water tank into the engine of the channel, when the engine temperature is about 93-98 of the body's arrival, the thermostat engine open, cooling fluid from the thermostat back into the tank....

- Q: I bought a new water pump for my 89 S10 Blazer with the 4.3 V6. The guy at Autozone wanted to know if I wanted a standard one or the heavy duty. I bought the heavy duty one because it was only $5.00 more. Are they just built stronger or do they actually move more water?

- Mistake #1. Auto Zone doesn't stock anything close to the quality as an OEM part. If you want a better than average OEM water-pump get an aluminum Stewart Stage 1, 2, 3 or 4. The impeller builds more engine and cylinder head coolant pressure which prevets steam pockets in the heads. Little does Jason know that not all water-pumps created equal.

- Q: I live in a house that uses a pump to push water from a tank to the bathroom and kitchen. It has a sensor that detects if water is flowing and pushes it much harder. Recently, it has been pushing the water for a second or less then it completely stops for a while. It's like a pulse of water then nothing. Can anyone give me feedback on what is wrong here? Thank you.

- from okorder :Self-priming pump working principle is: the pump before you start in the pump shell filled with water (or) from the water in the pump housing.Start after high-speed rotating impeller flow to the vortex in the impeller, shell, then the entry form the vacuum, the inlet non-return door open, within the air into the pump suction tube and the impeller, to arrive at the outer edge.Self-priming pump is a self-priming centrifugal pump, it has compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life, and have strong self-priming capacity, etc.Line does not need to install the bottom valve, only to ensure storage in pump body before work are quantitative liquid.Pump after the normal starting, impeller liquid of suction chamber and inlet line of air suction, and can completely mixed within the impeller, the function of centrifugal force, and liquid with gas to the vortex flow volume outside edge, the impeller has a certain thickness is formed on the outer edge of the white foam belt and high-speed rotating liquid ring.Gas-liquid mixture into the gas-liquid separation chamber through diffusion tube.At this time, due to the flow rate suddenly drops, lighter gas is separated from the mixture of liquid and gas through the pump body spit continues to rise.After degassing of liquid to liquid storage chamber, and the reflux hole again into the impeller, and impeller with inhalation of gases from the inlet line again mix, flow under the action of the high-speed rotating impeller and the impeller outer edge....As the process cycle, decreasing the air in the suction line, until all gas absorption, complete the self-priming process, pump put into normal operation. What you said phenomenon should be pipeline leak, which leads to the self-priming pump process is repeated.

- Q: and how do I get it to work 24 hours a day?and on the pump there is written: 2 A, and on another part: 220-240 Vdoes that mean its wattage is 440-480Watt?

- Hey Don ..did you mean consecutive hours..if so. Here is how to do it..If there is fluid to be pumped there is sometimes a controller that will ask the pump to stop when it reaches low level . And again ON when it senses high level. Find this device, if one exists and either defeat it mechanically or wire around it electrically.Either is pretty simple. NOW that i have told you how to get it to run all the time. I though I might mention a timer..A timer, in series with your pump, will cut it off and give the liquid level a chance to rise as well. Timers can be defeated the same as all other protective devices,, My question is Are you sure this is what you want to do ? The plug on the end of the cord ,it must be a small pump if only 2 amps, should be your only control .If it has an auto off feature it's there to save your pump from burning the barn down ,so to speak, Why not take another look at your application. if you do have an endless fluid supply ,like a closed loop trickling fountain, remember those evaporate if make up water is not added. Sometimes though you need a pump to run 24-7 in which case just fool the controller..Of course the human is the true controller... :) Well I have armed you with enough info to get by on this please do so safely. From the E...

- Q: Is a 3000 watt generator sufficient to power a 3/4 horsepower water pump?My house has a 3/4 horsepower pump that it uses to pump water from the well to the house. I want to purchase a generator that will be sufficient to power this pump in a power outage. Is 3000 Watts sufficient?

- 1 hp is 746 watts; however start up and power factors need to be considered. A 0.75 hp motor at steady state draws 560 watts at steady state; to overcome start up assume you will need about 1,100 watts (1.1 KW). Your generator is 3 KW so it should do well.

- Q: 22KW pump motor direct start circuit breaker and contactor size? Concrete calculation method

- It's better not to start directly. It's a great test for your motor and contactor. Do a star three start, conditional on doing a star three plus autotransformer start, reducing the starting current. Reduce future maintenance costs. Since do not think about every day to do pump repair.

- Q: implementation of regulator in water level control system

- This might be explained with an example. There is a water tank being used by a community (or a dwelling) and it is supplied by a pump from a well. There is a switch in the tank that is wired to the pump motor. The switch is activated by a lever attached to a float in the tank. When the float is in the down position the pump runs, When the float is pushed up by the water the punp is turned off. The pump first operates and fills the tank and then shuts off when the tank is full. When the usage of water drops the water in the tank to a certain level, the pump turns on until it is full again. The float, the switch and the motor are the pump regulating devices. This type of regulation is called two-position, like a light switch. Other more involved types of regulation may adjust a valve in the pipeline from the pump . This changes the rate of flow while the pump continues to run. The first type of regulation can be called digital because the flow is yes or no. The second can be called analog because while it is on, the flow varies in amount. If I have not adequately answered your question, maybe someone else will.

- Q: There is a loud squeecking noise coming from the water pump and the serpentime belt isnt loose!I dont know how long it would take a mechanic to do the job?

- Spray some water on the belt while it's schreeching to rule the belt out. They often make noise, even when tight.

- Q: I have some black RTV silicone that I got with a gasket for my oil pan. Can I use some on a gasket for a water pump instead of regular sealant or is there a particular type I need? If there is a certain or preferred type please give me a link to it at like autozone or something, thanks!

- in the event that they are metallic yet lined in black stuff, then the black stuff is the silicon. i like to place an particularly skinny layer of liquid gasket on my moist seals (different than the headgasket). Use the paintbrush and use the liquid gasket very sparingly. ingredient being, in case you for regardless of reason do not positioned it on with a hundred% of a seal or regardless of, this is one extra layer of protection on your cooling equipment. It additionally glues the gasket to the area, which makes it elementary to place in.

Send your message to us

HZJ Series Heavy Duty Slurry Pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords