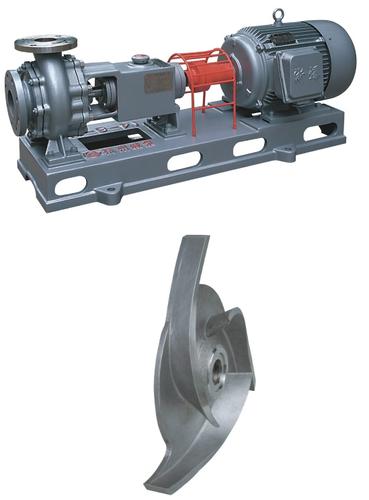

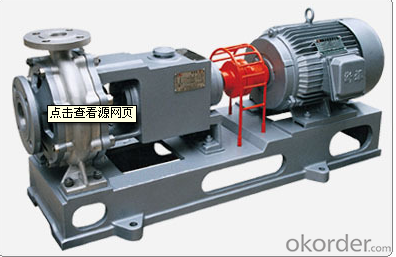

AZ Series Pulp pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description

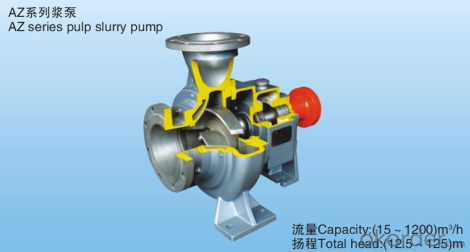

AZ series pulp pump is the improved product of the HT series pulp pump, which is a sucessful design based on long-term technology accumulation and on the experience of domestic and overseas advanced technology. The pump has a strong capacity to convey fiber, particles, the pulp below 8% density and other liquid with the solid content below 30%. It can be used in those operating environments in the paper making, metallurgy, fertilizers salt collecting, drainage and power plant etc.

2. Application

Soda and inorganic salts

Metallurgy

Iron and steel industry

Acid-making industry

Petrochemical industry

Fiber and plastic industry

Paper-making industry

Chemical fertilizer industry

Fermentation industry

Environmental protection

3. Technical Data

The max working pressure: 2.0MPa

Capacity: 6~1200m3/h

Head: 5~125m

Temperature: -20~200℃

The pulp consistency ≤ 8%

The solid content ≤ 30%

4. Materials

For wetted parts in contact with medium, the common materials are as follows:

Stainless steel 304, 321, 316L, 310Cu, 0Cr25Ni6(dual-phase stainless steel), alloy 20#, 904L, TA2, Ti/Pd, Ni, Monel etc.

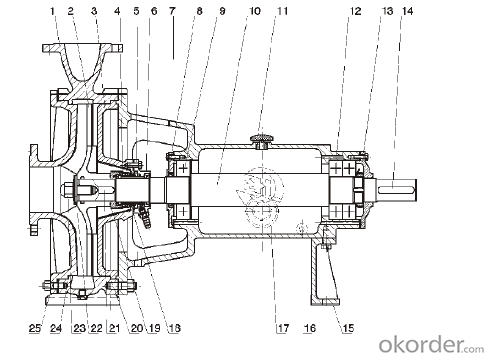

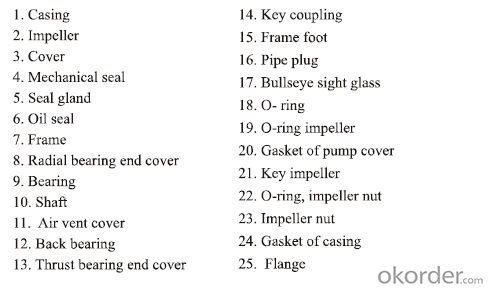

5. Pump Structure

6. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

4 Can your pumps mount Eff.1 motors

Currently, only on request though this will shortly be a CNBM standard.

5 Are your pumps protected against dry running?

No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

- Q: I need to get my water pump replaced because it is cracked, a coolant flush and my belt is dry. I went to pep boys because my check engine light came on.They want to charge me 950 for the job. I am reluctant to pay that much. I drive an '06 Pontiac Torrent. I am suppose to take my car in today but I am not sure if I am being ripped off or not. Is 950 too much?

- I would say that $950 is a very high price for a new water pump, considering that the pump by itself is less than $70. It should not take more than 3 or 4 hours to replace, so even setting aside $250 for the pump, belt, and flush (even that is a high estimate of the cost of those materials), that would mean that they are charging between $175 and $230 per hour to work on your SUV. I would recommend that you see if a male relative or friend can ask for a quote for the same work as I feel they are trying to rip you off. When I was in the Navy, a local repair shop charged my wife almost $900 for the replacement of a $50 ignition part that took 5 minutes to replace. When I returned from that deployment, I asked them for a quote for the same work and they gave me a written quote of $150.

- Q: I recently bought a 1992 Honda Accord. It has high mileage but the records kept on it were impecable up to about the last 3 years. I have read that you need to replace the timing belt/water pump every 80k miles. However; I do not know when it was changed last. The Only record in the book on the subject was back at 90k miles. That was the first time they had the timing belt changed.So How do I know its time to change it again? The car now has 199k miles. I do not want to do unnecessary work before time, however; I also know that the affects it will have on the engine is great if its not done within the right TIME! Is there anyway to know it needs to be done? What kind of signs will the car give? And how much is it going to cost me when it has to be done? Thanks!

- A water pump is mostly pretty obvious when it is going/gone it chirps it squeaks and your temperature will usually be higher than it usually was [not always]. As for a timing belt... they are relatively inexpensive, the labor isnt that bad since the car is VERY easy to work on, and it is difficult to tell when one is needed since the most it will make is a whining noise when its getting weaker, only sometimes though. This is hard to hear too. Best advice I have is to just get a couple appraisals/estimates, or have a friend who is mechanically savvy take a look to see if he/she can tell if the belt is worn to the point where it needs replacing. I had a timing belt done for $120 parts and labor on a 91 accord (same car)

- Q: How much is the flow rate of fire hydrant and spray shared water pump?

- Fire fire water is superimposed, at the minimum, the lowest 5L/S automatic spraying fire hydrant, light danger level 13.9L/S, the least is 18.9L/S, but the data is useless, the data are not spraying fire hydrant, concrete analysis of high-rise buildings like the dangerous level according to the calculation, the general design, the concrete building needs the high-rise building minimum 20L/S, automatic spraying dangerous level according to the general 30L/S, 50L/S need to flow

- Q: need to know the electrical connections for a Square D water pump pressure switch..Have a quot;blacka quot;Redand the quot;ground quot;of course

- The two source wires connect to L1 and L2. The two pump wires connect to T1 and T1. The grounds get grounded. When the pressure falls, the contacts pull together and connect L1 to T1, and L2 to T2, and start the pump.

- Q: Do it yourself steps

- This Site Might Help You. RE: 1995 Honda Civic water pump replacement steps? Do it yourself steps

- Q: I posted this earlier but nobody really answered my question . if my water pump is clearly on the serpentine belt I t need to replace the timing chain to get to it correct? The bolts holding the pump in are around it near the timing chain cover but they don't look like they are inside it. the pump is clearly driven by the serpentine so should I be fine not removing my timing belt to fix the pump? its leaking. Also I know you should replace the timing chain+tensioner but I inspected the chain 400 miles ago its properly tensioned the belt is in good condition its a chain it will last the life of the car its not the cheap belts.

- Are you forgetting to mention something? Ah! Year, Make and Model. Engine size is a plus ... only a fool who knows nothing will answer your question without knowing the at least needed to know information ... What do you mean: if my water pump is clearly on the serpentine belt I t need to replace the timing chain to get to it correct? You've said: Timing chain and yet, the first answer by You may be right said: If you can change the pump without removing the timing belt then go for it, you are lucky. See what has happened when the needed to know information were not specified? .. and how do you expect any of us to know the question you have mentioned before and could not read your history in YA? I've rest my case ...

- Q: 1997 Chevy Cavalier, 2.2 engine. In the past 2 days I noticed that my temp gauge was reading a little higher than usual but not in the danger range. I checked and nedded to add coolant. Last night it started making a chattering or maybe klunking sound. As far as I could tell it was coming from the water pump but it stopped before I could get out of the car and look to see. Now the coolant is low again. Are these signs of the water pump being bad or could it be something else?

- There could be alot of causes to water lose and slight elevation in temp. If the water pump is leaking most often you will see sings of it at the water pump. Also you may want to check the oil. I know it sounds crazy but see if the oil is a whitish color. You may have a blown head gasket and could be leaking water into the cylinders from the water jackets in the head. Hope that helps. Also check the ground after the car has been sitting and running. If you see water look up from the ground to see if you can locate the leak.

- Q: I would like to change the water pump myself but do not have a repair manual.

- Do you have the 3.4 or the 3.8? Oh well. No one bothers to give that sort of vital information on here... Don't forget to buy RTV when you go buy the pump. Anyway, the 3.4: To Remove: Drain the cooling system. Remove the drive belt guard if equipped. Loosen the water pump pulley bolts. Remove or disconnect the following: Drive belt. Water pump pulley bolts and pulley. Water pump bolts, pump and gasket. Clean the water pump mating surfaces. To Install: Install or connect the following: Water pump gasket and pump. Water pump bolts. Tighten the water pump bolts to 10 Nm (89 inch lbs.) Water pump pulley and bolt until snug. Drive belt. Tighten the water pump pulley bolts to 25 Nm (18 ft. Lbs.). If removed, install the drive belt guard. Fill the cooling system. Inspect for leaks. For the 3.8: To Remove: Drain the cooling system. Loosen the water pump pulley bolts. Remove or disconnect the following: Drive belt. Water pump pulley bolts. Water pump pulley. Power steering pump and reposition. Water pump bolts. Water pump. Water pump gasket. Clean and inspect the water pump mating surfaces. To Install: Install or connect the following: Water pump gasket. Water pump. Tighten the long water pump bolts to 34 Nm (25 ft. Lbs.) Tighten the short water pump bolts to 22 Nm (16 ft. Lbs.) Water pump pulley. Water pump pulley bolts. Tighten the bolts to 13 Nm (115 inch lbs.) Power steering pump. Drive belt. Fill the cooling system. You're lookin' at eight bolts on the pump in most vehicles your make/model.

- Q: In this area (picture) its leaking quite a bit of coolant underneath the car it is heavy dripping. Could it be the water pump? Car is over heating .It almost looks like its missing a screw or something where the coolant is dripping.

- You're trouble could be one among two.....The gauge cluster could be bad and want exchanged out(the dealer does no longer restore them),or the gasoline sender(or flow/level sensor)which is attatched the the gasoline pump(does no longer include pump)could be inaccurate.The vendor or repair facility easily makes use of your old sender when changing the pump(which is a dumb thing to do once they have already got the tank out of the auto).And oh incidentally........A GMC is nothing more than a re-badged Chevrolet....And were considering that 1996 once they stopped making GMC seperate on the truck and bus plant and diverted all manufacturing to the Chevrolet crops....Equal construction line,distinctive title plates,do not let anybody fool you about GMC being reliable grade,no more durability...Just more money !

- Q: As a fact; I must remove the timing belt in order to remove both camshaft sprockets,then the metal timing belt cover which cover partially the water pump.My main question: Do I have to lift the engine and remove the two water pump studs- Which normally holding the right engine mounting.And where I can rent ,or buy a camshaft locking tool with low price

- Yes, I have done at least 100 of these water pumps. You are correct, remove the timing belt, cam gears and rear cover is the easiest route. I have done them without removing the rear metal shield all the way, and only removing the front cam gear as well. You can remove the front cam gear, and all 6 bolts to the rear shield and shift the cover enough to get the pump out from behind the cover. You shouldn't need to remove the water pump studs, but if you do get a set of stud removers. I bought a set from snap on for around $50 or so years ago. Sears also sells a set. You don't need a cam locking tool. You can make one out of a bar with two bolts through it to stop cam from rotating while you loosen the 17mm nut on the cam gear. I usually just use an impact gun on the bolt, and no tool is needed to hold it. Remember, the 1MZ-FE engine is an interference engine, and the timing belt must be aligned perfectly or the pistons WILL hit valves and engine will self destruct. If you are near ILlinois I can help with repairs if needed.

Send your message to us

AZ Series Pulp pump(ISO2858, ISO5199, API682)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords