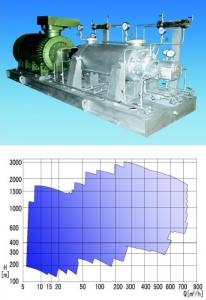

Horizontal Mixed Flow Pump HW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal Mixed Flow Pump Product description

Axial-flow pumps are modern products successfully designed through adopting foreign modern technology. The new pumps’ capacity are 20% larger than the old ones. The efficiency is 3%-5% higher than the old ones. QZ series pump with adjustable impellers has the advantages of large capacity, broad head, high efficiency, wide application and so on. Pump station is small in scale, the construction is simple and the investment is greatly decreased. This can save 30%-40% for the building cost. It is easy to install,maintain and repair this kind of pump. Low noise,long life.

Horizontal Mixed Flow Pump Application

Axial-flow pump is applicable for water supply in cities, diversion works, sewage drainage system, sewage disposal project.

Horizontal Mixed Flow Pump Technical Data:

Flow rate: up to 20 m³/h

Head: up to 20 m

Speed: max rpm

Temperature: max °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

Material: nodular iron, stainless steel, duplex

- Q: I need information about basic water pumps. I'll have to build a mechanical one for school. Do you have any ideas, information, designs, links? Thanks!

- A very simple and old design for a water pump is called the ball-chain or bucket-chain pump. A google search should show you what they are. Building one should be fairly straightforward and simple.

- Q: I would like to ask the river for about 70 degrees on the steep slope pumping 170 meters, flat 40 meters into the pool, what should I choose water pump? How many heads? How to choose the water pump model? Thank you

- Pump selection parameter:1, lift, if the head is large, the use of multi-stage vertical centrifugal pump, if the head is small, the use of horizontal axial flow centrifugal pump2. Displacement3, suction stroke, if the suction range is short, select the submersible pump, suction distance, select centrifugal pump

- Q: The water is being put in because it was overheating. We changed the thermostat and everything and it got better, but about a month later it started overheating again and now it is leaking water bad from underneath the car. Whatever is leaking is covered by a shield thing. Im not sure what it is, and I dont want to replace it before I know if thats really what it is. Any help would be greatly appreciated.

- If the leak is on the passenger side of the car (near the tire) then it is most likely your water pump. It is driven by the serpentine belt that drives most of the visible components on the passenger side of the engine. (power steering, A/C, Alternator etc) To check it, you need to look UNDER the water pump, it has a weep hole. If this small (1/8) hole is wet, or shows signs of having been leaking (like discoloration or rust) then your waterpump seals or bearings are going. The unit must be replaced. This should also fix your over heating problems. If the leak is near the back-center of the engine, then it may be a frost plug (also called a freeze plug) these are designed to pop if the enging coolant freezes to prevent damage to the engine block, they can also be opened if the engine over heats. Be careful when replacing this plug, if you drive it INTO the engine, you will have to dismantle the engine to get it out again. On the plus side, you can get rubber plugs that are easy to install and quite inexpensive. I'd place the water pump as the most likely problem.

- Q: are there any pumps that can save energy more? Environmental protection is necessary and the price is not high.

- Water pump. ( Pond ) Sump pump. ( Flood prevention ) Auto water pump. ( Radiator ) What is the specific purpose of the pump.

- Q: I recently bought a 1992 Honda Accord. It has high mileage but the records kept on it were impecable up to about the last 3 years. I have read that you need to replace the timing belt/water pump every 80k miles. However; I do not know when it was changed last. The Only record in the book on the subject was back at 90k miles. That was the first time they had the timing belt changed.So How do I know its time to change it again? The car now has 199k miles. I do not want to do unnecessary work before time, however; I also know that the affects it will have on the engine is great if its not done within the right TIME! Is there anyway to know it needs to be done? What kind of signs will the car give? And how much is it going to cost me when it has to be done? Thanks!

- A water pump is mostly pretty obvious when it is going/gone it chirps it squeaks and your temperature will usually be higher than it usually was [not always]. As for a timing belt... they are relatively inexpensive, the labor isnt that bad since the car is VERY easy to work on, and it is difficult to tell when one is needed since the most it will make is a whining noise when its getting weaker, only sometimes though. This is hard to hear too. Best advice I have is to just get a couple appraisals/estimates, or have a friend who is mechanically savvy take a look to see if he/she can tell if the belt is worn to the point where it needs replacing. I had a timing belt done for $120 parts and labor on a 91 accord (same car)

- Q: Why should we pump water into a pump when the country uses a pump to pump it?

- Because the leather cushion there is not completely sealed the water pump wall, there is a small gap in the contact, so that the piston up and down the air connection, air pressure is equal, can not pump water.And then add water to the gap closed, such upward pull the piston to make the piston below the space increases, but the air and can not go to fill the air pressure decreases, less than atmospheric pressure, only through inhalation of water to supplement water, which is forced by atmospheric pressure wells the water through the pipe and then rise to the pump. So it can be pumped up.

- Q: What are the commonly used tools for repairing water pumps? Mainly for civilian 220V submersible pumps, self-priming pumps. How much is the spare parts ready for use?

- Because had done a mechanic, and relates to a pump, not including motor repair, commonly used tools: pliers, pliers, adjustable wrench, wrench, screwdriver, bench drill, multimeter, electric iron, Lamar, hammer, ruler, chisel. Commonly used parts: bearings, impellers, screws, terminals, lubricants and so on.

- Q: Here we have 3 sets of centrifugal pumps, as production water, 2 by 1, because the production is not allowed to stop, so we want to change for a pump, the original two pumps to stop, and three water pumps on the amount, and then stop the pump, but not on the third pumps the amount, do not know what the reason, the master to help, thank you very much..

- The problem you are experiencing is stressThe above answer is only considered in the case of water absorptionJust imagine, two pumps are normal work, the same suction pipe, how can there be dissatisfaction with water or vacuum state?.According to my experience analysisYour system is three sets of parallel, lift and flow should be the same, if not the same, not in this discussion, the topic should be set up.Lift is the same, that is, in two or three units at the same time, the resulting system pressurization is the same, and water will increaseBut now your traffic is increasing at two units, but it will not increase at threeYou have selected pipeline system design, in the design of head flow under single condition is constant, if the increase in open water pump, the pressure is constant, increasing water content, according to the continuity equation Q = A X V, then the flow velocity in the tube will increase;But when the third pumps, 2Q becomes 3Q, normally velocity should be larger, but the Darcy formula shows that the velocity increases, extension resistance and local resistance will be increased, and the double square, so you can open third pumps for reasoning, when the resistance effect caused by the pipeline the increase of water flow in the pipeline can not be reused, the general formula of constant current, now the whole pipeline in turbulent stateThat is, third pumps to do the work in the water and pipe wall friction in the loss, and actually did not play a role in water supplyThe solution is to increase the flow rate by increasing the water supply pipeline

- Q: leaking coolant after the car engine has stoppped

- Some water pumps have weeping holes, if water is coming out of those then it is definitely your problem.

- Q: The role of impeller in water pump

- The impeller rotates at high speed so that the centrifugal force is generated by the water, and the vacuum is generated in the middle of the impeller, and the water source is continuously sucked into the impeller to increase the kinetic energy of water and play a role in promoting water.

Send your message to us

Horizontal Mixed Flow Pump HW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords