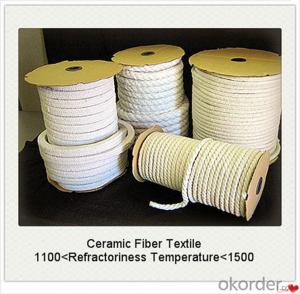

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Ceramic fiber cloth

2.1260C

3.thickness:1-5mm

4.reasonable price

High temperature ceramic fiber refractory fabric for heat insulation

Specifications:

Temperature:450C-1260C

Thickness:1.5mm-6.0mm

Width:500mm-1200mm

Density:500kg+/-30kg/m

Reinforcing materials: glass fiber wire, stainless steel wire

1. Products Details:

Hitex Ceramic Fiber Cloth is a woven fabric made from our high quality ceramic fiber woven yarn. The cloth is reinforced with fiberglass filament, or optional Inconel/alloy steel wire reinforcement. It is featured with heat insulation and high temperature protective materials in all kind of thermal installations and heat-conducting systems, widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, shipyards, refineries, power plants and chemical plants.

2. Product Advantages:

1.Resistance to high temperature and chemical erosion

2.High mechanical strength

3.Low thermal conductivity

4.Low thermal storage

5.Resistance to heat shock

6.Easy installation

3. Technical Data:

Item | Ceramic Fiber Cloth | |

Classification Temperature | 1260C | 1260C |

Work Temperature | 450C | 1000C |

Basic Material | Fiberglass Reinforced | Stainless Steel Reinforced |

Theoretical Density ( kg/ m3) | 500±15 | |

Moisture Content (%) | ≤2 | |

Warp Density | 48~60 Piece/10cm | |

Weft Density | 21~30 Piece/10cm | |

Organic Content (%) | ≤15 | |

Specification (mm) | L:30,000mm / W:1,000mm / T:2~3mm | |

Packing | Plastic bag inside, woven bag outside | |

- Q: Are glass fiber textiles resistant to corrosion?

- Yes, glass fiber textiles are resistant to corrosion. Glass fibers are made from molten glass that is spun into fine threads, which are then woven into textiles. The glass fibers themselves are chemically inert and do not react with most chemicals or substances, making them highly resistant to corrosion. This corrosion resistance is further enhanced by the fact that glass fibers do not absorb moisture, preventing the growth of mold or mildew that can lead to corrosion. Additionally, glass fiber textiles are also resistant to UV radiation, which can cause degradation and corrosion in other materials. Therefore, glass fiber textiles are an excellent choice for applications where corrosion resistance is required, such as in the construction of chemical storage tanks, pipes, or other corrosive environments.

- Q: Are glass fiber textiles resistant to tearing during stretching?

- Glass fiber textiles, in general, exhibit resistance to tearing when subjected to stretching. The high tensile strength of glass fibers enables them to endure substantial stretching forces without experiencing tearing or breaking. This quality renders them highly suitable for various applications that prioritize durability and resistance to tearing. Examples of such applications include the manufacturing of high-performance fabrics, reinforcement materials, and composites. Nevertheless, it is crucial to acknowledge that the precise resistance to tearing might fluctuate depending on the particular construction and processing methods employed in the production of the glass fiber textiles.

- Q: Are glass fiber textiles lightweight?

- Yes, glass fiber textiles are lightweight.

- Q: How do glass fiber textiles affect breathability?

- Breathability can be significantly influenced by glass fiber textiles. Unlike natural fibers like cotton or linen, glass fiber textiles are not as breathable due to their inherent properties. This is because glass fibers have lower porosity, making it more difficult for air to pass through. The use of glass fiber textiles in clothing or other products can restrict the movement of air through the fabric, resulting in reduced breathability. This can cause discomfort for the wearer, especially in warm or humid conditions where proper ventilation is essential for maintaining a comfortable body temperature. However, it is worth noting that advancements in textile technology have led to the development of glass fiber textiles that offer improved breathability. Manufacturers have implemented various techniques to enhance the porosity of glass fiber fabrics, such as incorporating micro-perforations or combining them with more breathable materials. These innovations have helped alleviate the breathability concerns associated with glass fiber textiles to some extent. In conclusion, while glass fiber textiles may not match the breathability of certain natural fibers, continuous research and development efforts are continuously enhancing their breathability. This makes them increasingly suitable for applications where comfort and ventilation are crucial factors.

- Q: Is glass fiber textile lightweight?

- Glass fiber textile is indeed lightweight. It is produced by weaving thin strands of glass together to create a textile material. This material is renowned for its lightweight attributes, which has led to its widespread use in numerous industries like aerospace, automotive, and construction. The lightweight nature of glass fiber textile enables easier handling, transportation, and installation, while still delivering impressive strength and durability. Moreover, its low weight contributes to energy efficiency in applications such as insulation and composites. All in all, glass fiber textile is the perfect option when a lightweight material with exceptional performance qualities is needed.

- Q: Are glass fiber textiles suitable for filtration applications?

- Yes, glass fiber textiles are highly suitable for filtration applications. Glass fiber textiles have excellent filtration properties due to their fine and dense structure. They are capable of capturing and retaining small particles, making them ideal for use in air and liquid filtration systems. Glass fiber textiles have a high filtration efficiency and can effectively remove pollutants, dust, and other contaminants from air or liquid streams. Additionally, glass fiber textiles are resistant to chemical degradation and can withstand high temperatures, making them suitable for applications where harsh environments are involved. They are widely used in industries such as automotive, aerospace, pharmaceuticals, and water treatment, where efficient filtration is crucial.

- Q: Can glass fiber textiles be used in reinforcement of nanocomposites?

- Yes, glass fiber textiles can be used in the reinforcement of nanocomposites. Glass fiber textiles are known for their high strength, stiffness, and impact resistance, making them ideal for reinforcing materials. Nanocomposites, on the other hand, are materials composed of a matrix material and nanoscale fillers, such as nanoparticles or nanotubes, which enhance the mechanical and physical properties of the composite. By incorporating glass fiber textiles into nanocomposites, the resulting material can benefit from both the strength and stiffness of the glass fibers and the enhanced properties provided by the nanofillers. The glass fibers act as a reinforcement, improving the overall mechanical performance and durability of the nanocomposite. The nanofillers, on the other hand, can enhance specific properties, such as thermal conductivity, electrical conductivity, or flame resistance. Furthermore, the compatibility between glass fibers and the matrix material of the nanocomposite is usually high, allowing for effective load transfer and improved mechanical properties. This compatibility ensures that the glass fibers are efficiently incorporated into the nanocomposite structure, providing the desired reinforcement. In summary, glass fiber textiles can indeed be used in the reinforcement of nanocomposites, combining the strength and stiffness of the glass fibers with the enhanced properties offered by the nanofillers. This combination results in a material with improved mechanical performance, making it suitable for a wide range of applications in various industries.

- Q: Can glass fiber textiles be used in tents or camping equipment?

- Yes, glass fiber textiles can be used in tents or camping equipment. Glass fiber textiles, also known as fiberglass, are widely used in the manufacturing of outdoor gear due to their durability, strength, and resistance to weather elements. These textiles can be used in tent poles, tent fabrics, and other camping equipment such as backpack frames, sleeping bag poles, and lightweight furniture. The use of glass fiber textiles in tents and camping equipment provides excellent stability, flexibility, and longevity, making them a popular choice among outdoor enthusiasts.

- Q: Can glass fiber textiles be used in insulation pipes?

- Indeed, insulation pipes can make use of glass fiber textiles. Owing to their remarkable thermal insulation characteristics and ability to withstand high temperatures, glass fiber textiles are frequently employed in insulation applications. By effectively insulating against heat, they hinder the transmission of heat either from the inner to the outer part of the pipe or vice versa. Moreover, glass fiber textiles possess the advantages of being lightweight, flexible, and durable, rendering them appropriate for utilization in insulation pipes. They can be conveniently wrapped around the pipe and securely fastened, thereby offering a dependable and efficient insulation solution.

- Q: Can glass fiber textiles be used in reinforcement of bio-based composites?

- Yes, glass fiber textiles can be used in the reinforcement of bio-based composites. Glass fiber textiles offer excellent strength and stiffness properties, which make them suitable for enhancing the mechanical properties of bio-based composites. The combination of glass fiber textiles with bio-based materials can result in composites that have improved performance, durability, and structural integrity.

Send your message to us

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords