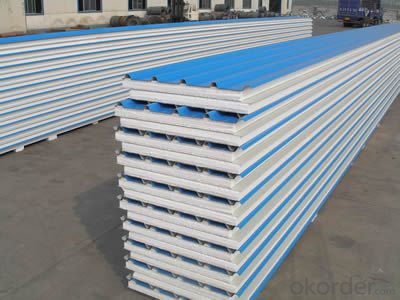

Galvanized Color metal glass wool sandwich panel for roofing and wall and warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1) light weight.roof tile2) high strength

3) waterproof and fireproof

4) fast and convenient construction

The galvanized color steel sandwich panels are polystyrene sandwich panels, which is very good at heat insulation.

1. The width of the sandwich panel is 930mm, and 1,150mm

2. Upper and lower layer: uses color steel plate

3. Thickness of the color steel plate: 0.3 to 0.6mm

4. Middle: polystyrene foam board

5. Thickness: 50mm, 75mm, and 100mm, 200mm, 300mm, etc.

6. Length: according to customer's request

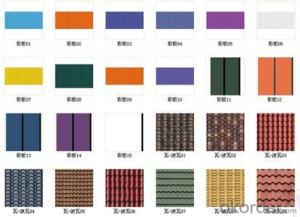

7. Color: white, green, blue, red, etc.

8. The products has good at warm keeping, and it is in low price

Base metal: PPGI,prepainted steel panel

Content of composite panels: Foam or Rock wool

Appliance: Wall panel and roof panel

Type of wall panel: one-side iron with foam;bottom with silver paper foam composite steel panel;bottom with film foam composite steel panel;jack type composite steel composite panel etc.

Type of roof panel: PVC and both sides iron panel;rock wool roof panel has buckle-style panle.

Thickness of foam: 5,7.5,10 cm

Weight of foam: 7,8,12 kgs

Thickness of rock wool: 5,7.5,10 cm

Weight of rock wool: 7,8,12 kgs

The colors,patterns,thickness of steel panel,measures are all designed by customer's request.

Packing the pipes into the bundles by the steel strip (2)packing the welded steel structure parts by some fabric (3)packing the small parts by bags and EPS foam (4)packing sets parts by some box or stock

- Q: How do steel structures contribute to sustainable building practices?

- Steel structures contribute to sustainable building practices in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions and has a long lifespan. This reduces the need for frequent maintenance and replacement, resulting in less waste generation and reduced use of resources. Additionally, steel is a recyclable material, which means that it can be recovered and reused at the end of its life cycle, reducing the demand for virgin materials and minimizing environmental impact. Furthermore, steel structures can be prefabricated off-site, resulting in reduced construction time, lower energy consumption, and minimized disturbance to the surrounding environment. Overall, steel structures offer sustainable building solutions by promoting long-term durability, recyclability, and efficient construction practices.

- Q: How are steel structures used in the construction of bridges?

- Steel structures are commonly used in the construction of bridges due to their high strength-to-weight ratio and durability. Steel is often used as the main material for the bridge's structural elements, such as beams, girders, and trusses, providing the necessary support and load-bearing capacity. The versatility of steel allows for the construction of various bridge types, including suspension, cable-stayed, and arch bridges. Additionally, steel structures offer ease of fabrication, transportation, and installation, making them a popular choice in bridge construction.

- Q: How are steel structures used in museums and cultural buildings?

- Because of their numerous advantages, steel structures are widely utilized in museums and cultural buildings. Their strength and durability allow for the construction of spacious and open areas without the need for excessive support columns or walls, which is crucial in accommodating various exhibitions and displays. Furthermore, steel structures offer a high level of design flexibility, enabling architects to create visually stunning and distinct buildings. The malleability of steel allows for the formation of iconic architectural elements like curved roofs, cantilevered structures, and long-spanning bridges. These features greatly enhance the visual appeal of museums and cultural buildings, making them more appealing to visitors. Additionally, steel structures are relatively lightweight compared to other construction materials, making them an ideal choice for constructing large structures with minimal impact on the existing site. This is particularly important in historical or heritage buildings, where preserving the existing structure is of utmost importance. The integration of steel structures into these buildings can be done seamlessly without compromising their integrity or architectural significance. Moreover, steel structures offer practical advantages in terms of construction speed and cost-effectiveness. The prefabrication of steel components in a controlled factory environment allows for faster and more efficient on-site construction, reducing overall construction time and minimizing disruptions to the museum or cultural building's operations. Furthermore, steel is a highly sustainable material as it can be recycled without losing its properties. This makes it an environmentally friendly choice for museums and cultural buildings that aim to reduce their carbon footprint. Additionally, steel structures have a long lifespan and require minimal maintenance, resulting in reduced operational costs and ensuring the longevity of these important cultural institutions. In conclusion, steel structures play a vital role in museums and cultural buildings by providing the necessary strength, flexibility, and visual appeal required for these unique architectural spaces. Their ability to create large, open spaces, their design flexibility, and their sustainability make them a popular choice among architects and engineers alike.

- Q: How are steel structures designed to accommodate building movement?

- Steel structures are designed to accommodate building movement through several methods. One common method is the use of expansion joints, which allow the structure to expand and contract with temperature changes without causing damage. Additionally, engineers incorporate flexible connections and joints into the design to absorb movement caused by wind, seismic activity, or other external forces. These flexible connections help distribute the forces and stresses throughout the structure, ensuring its stability and integrity.

- Q: How do steel structures contribute to the overall indoor air quality of a building?

- Steel structures can contribute to the overall indoor air quality of a building in several ways. Firstly, steel is an inorganic material that does not release volatile organic compounds (VOCs) or other harmful emissions into the air. This is in contrast to certain building materials, such as wood or certain plastics, which can emit VOCs that can negatively affect indoor air quality. Additionally, steel structures are typically more resistant to moisture and mold growth compared to other materials. Moisture and mold can lead to the release of airborne contaminants and allergens, which can have detrimental effects on indoor air quality and the health of occupants. By providing a moisture-resistant and mold-resistant framework, steel structures help prevent these issues from arising and contribute to better indoor air quality. Moreover, steel structures often have a longer lifespan compared to other building materials. This longevity reduces the need for frequent renovations or repairs, which can disrupt indoor air quality during construction activities. Minimizing construction-related disturbances can help maintain a healthy indoor environment and prevent the introduction of dust, debris, or pollutant sources into the building. Furthermore, steel structures can be designed with efficient ventilation systems. Adequate ventilation is crucial for maintaining good indoor air quality as it helps remove stale air, odors, and pollutants, while introducing fresh air from outside. Steel structures can accommodate various ventilation systems, such as mechanical ventilation systems or natural ventilation strategies, to ensure sufficient air exchange and circulation within the building. Lastly, steel structures are often used in conjunction with sustainable building practices. Green building certifications, such as LEED (Leadership in Energy and Environmental Design), encourage the use of steel due to its recyclability and reduced environmental impact compared to other materials like concrete. By promoting sustainable construction, steel structures contribute to a healthier indoor environment and a reduced carbon footprint, ultimately benefiting overall indoor air quality. In summary, steel structures contribute to the overall indoor air quality of a building by being an inorganic material that does not release harmful emissions, resisting moisture and mold growth, minimizing construction disturbances, facilitating efficient ventilation systems, and supporting sustainable building practices.

- Q: What are the design considerations for steel platforms?

- Some design considerations for steel platforms include the load-bearing capacity of the steel, the structural integrity, the type and thickness of the steel used, the dimensions and layout of the platform, the required safety features such as guardrails and non-slip surfaces, the accessibility for maintenance and inspections, and the overall aesthetic appeal.

- Q: How are steel structures designed for wind pressure loads?

- Wind pressure loads pose a significant challenge for steel structures, requiring meticulous engineering to ensure their resistance to these forces. The design process is multifaceted, involving calculations, simulations, and adherence to building codes and standards. Initially, the design team assesses the wind pressure loads by considering the structure's location and exposure category. This step is crucial since wind loads can fluctuate due to variables such as wind speed, terrain, and height. The structural engineer then computes the maximum wind pressure the structure will encounter, accounting for factors like shape, size, and orientation. These calculations are typically based on wind tunnel tests, computer simulations, and historical data. Once the wind pressure loads are determined, the engineer proceeds to design the steel structure to withstand these forces. This entails selecting appropriate structural members (columns, beams, braces) and determining their sizes and configurations. Additionally, the design considers the connections between these members, ensuring their strength to bear loads and resist wind-induced forces. To enhance structural integrity, various features may be incorporated into steel structures to mitigate wind pressures. These can include aerodynamic shapes, such as streamlined or tapered sections, to reduce wind resistance. Furthermore, bracing systems (diagonals, cross-bracing) help distribute forces and enhance overall stability. Moreover, steel structures are designed in accordance with relevant building codes and standards. These codes establish guidelines and requirements for wind loads, structural design, and safety factors. Ensuring compliance with these codes is paramount for guaranteeing the safety and resilience of the steel structure. In summary, designing steel structures for wind pressure loads necessitates a comprehensive analysis of the environmental conditions and thoughtful consideration of multiple design factors. By employing advanced calculation methods, simulations, and adherence to building codes, engineers can create steel structures capable of withstanding wind forces and ensuring the building's safety and durability.

- Q: How are steel structures designed to resist earthquakes?

- Steel structures are designed to resist earthquakes through several methods. Firstly, they are designed with a flexible and ductile behavior to absorb and dissipate the energy generated during an earthquake. This is achieved by using steel members that can deform without losing their strength. Secondly, steel structures are often designed with redundancy, meaning that multiple load paths are created to distribute the seismic forces throughout the structure, reducing localized stress concentrations. Additionally, connections between steel members are designed to be strong and flexible, allowing them to move and deform during an earthquake without failure. Finally, steel structures are also designed with appropriate bracing and cross-bracing systems to enhance their lateral stiffness and resistance to seismic forces.

- Q: What are the guidelines for the fabrication and welding of steel structural members?

- The guidelines for the fabrication and welding of steel structural members are essential to ensure the integrity, safety, and performance of the structure. These guidelines involve several key aspects that need to be considered during the fabrication and welding process. 1. Material Selection: The first step in the fabrication process is selecting the appropriate steel material for the structural members. The chosen steel should meet the required specifications, including strength, ductility, and corrosion resistance, as specified by relevant codes and standards. 2. Design and Engineering: The fabrication and welding process should strictly follow the design provided by the structural engineer. The design should include details such as dimensions, tolerances, connections, and welding requirements. It is crucial to ensure that the fabrication process adheres to these design specifications to maintain the structural integrity. 3. Cutting and Shaping: Steel structural members often require cutting and shaping to achieve the desired dimensions and shapes. Guidelines for cutting methods, such as shearing, sawing, or flame cutting, should be followed to ensure accurate and clean cuts. Additionally, appropriate tools and techniques should be used to shape the steel members according to the design requirements. 4. Welding Procedures: Welding is a critical process in the fabrication of steel structural members. It is essential to follow specific welding procedures, including the selection of appropriate welding techniques, such as arc welding or gas welding, and the use of suitable welding consumables. Welding parameters, such as heat input, current, and voltage, must be carefully controlled to ensure proper fusion and minimize distortion. 5. Weld Quality: The quality of welds is of utmost importance in steel structural fabrication. Welds should be free from defects, such as cracks, porosity, or incomplete fusion, as these can compromise the strength and durability of the structure. Non-destructive testing methods, such as visual inspection, ultrasonic testing, or radiography, may be required to assess the quality of the welds. 6. Surface Preparation and Coating: Before welding, proper surface preparation is necessary to ensure good weld quality. This involves removing any contaminants, such as rust, oil, or paint, from the steel surface. The use of suitable cleaning methods, such as grinding or sandblasting, is essential to achieve proper adhesion and prevent defects in the weld. Additionally, appropriate coating systems should be applied to protect the steel members from corrosion. 7. Inspection and Quality Control: Regular inspection and quality control measures should be implemented throughout the fabrication process. This may involve visual inspections, dimensional checks, and non-destructive testing to ensure compliance with the specified requirements. Any deviations or defects should be addressed promptly to maintain the structural integrity of the members. Adhering to these guidelines is crucial for the successful fabrication and welding of steel structural members. By following these principles, the resulting structure will be safe, durable, and capable of withstanding the intended loads and environmental conditions.

- Q: What are the different types of steel roofs and skylights used in buildings?

- Let's delve into the various types of steel roofs and skylights commonly employed in buildings. 1. Standing Seam Steel Roofs: This particular steel roof type boasts vertical panels with raised seams that interlock, forming a waterproof seal. Its exceptional durability and resistance to weather conditions make it suitable for diverse building types, be it residential or commercial. 2. Corrugated Steel Roofs: These roofs are crafted from sheets featuring repetitive waves or ridges along their length. They are lightweight, cost-effective, and possess impressive strength and durability. Agricultural, industrial, and commercial buildings often opt for this option. 3. Steel Shingle Roofs: Steel shingle roofs mimic the appearance of traditional shingles but come with added steel benefits like durability, fire resistance, and longevity. With various styles and colors on offer, they are perfect for residential buildings seeking a classic aesthetic. 4. Steel Roof Tiles: Similar to steel shingles, steel roof tiles replicate the look of clay or concrete tiles. Alongside durability and low maintenance, they offer the same advantages as other steel roofing options. This option is commonly chosen by those desiring a tiled roof aesthetic in residential and commercial buildings. 5. Skylights with Steel Frames: Skylights are beloved features in buildings as they allow natural light to flood and illuminate interior spaces. To provide the necessary structural support, steel frames are often used. These frames guarantee strength and durability, ensuring the skylights remain securely in place. For optimal guidance in selecting the most suitable steel roof or skylight option for your specific building needs, climate conditions, and design preferences, it is crucial to consult with a professional roofing contractor or architect.

Send your message to us

Galvanized Color metal glass wool sandwich panel for roofing and wall and warehouse

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords