Cladding Sandwich Panels Color Steel Plate for Roof

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Containers Or With Other Clients' Requirements. |

| Delivery Detail: | within 15 days |

Specifications

1.high strength materials

2.quick lead time

3.competitive price.

4.Zinc Galvanized&Snowflakes

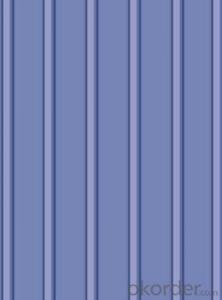

color steel plate for roof

Material | Galvanized steel sheet Galvalume steel sheet Pre-painted galvanized sheet | |

Coating | PE ,PVDF, galvanized(30-300g), galvalume (AZ80) | |

Model No. | YX25-207-828 | |

Sheet Thickness | 0.2-0.8mm | |

Sheet PeakHeight | 20mm | |

Sheet PeakSpacing | 265mm | |

Width | 920mm | |

Length | usually 5.8m or according the customers' demand,less than 11.8m | |

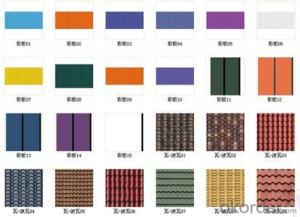

| Color | Standard color: red, blue, white,grey Special color: according to RAL color | |

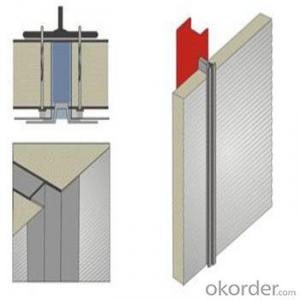

| Characteristic | 1.fire,water proof 2.heating insulation 3.fireproof 4.anti-rust 5. insulation 6.long useful life: more than 25 years | |

| Packing |

|

- Q: What is the difference between the board and the core board? The The

- General I-beam cross-section height of not less than 160mm

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- Can do the insulation that is the foam board, the so-called insulation of the extruded board with high Ji floating reed kill the devil ghost Tong Kankan Kun resistance, low linearity, low expansion characteristics of the structure of the closed-cell rate reached 99% Above, the formation of vacuum layer, to avoid air flow cooling, to ensure its long-term stability and stability, relative to the foam polyurethane 80% of the closed-hole rate, the leading advantage is self-evident

Send your message to us

Cladding Sandwich Panels Color Steel Plate for Roof

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords