Composite Sandwich Panels Insulated Fiberglass for Truck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | completely knocked down or WHOLE TRANSPORT |

| Delivery Detail: | abuot 15days |

Specifications

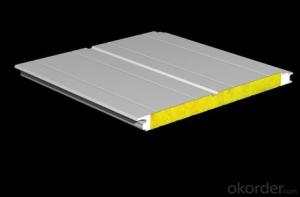

Insulated fiberglass sandwich panels for truck

1)Sandwich board

2)FRP panel

3)polyurethane insulated

4)s

Welcome To This Place

Description:

Type | refrigerator truck body, freezer vans box |

Truck type | Isuzu, FAW, Dongfeng, JAC, Foton and so on |

Range of size | 2-12m |

Capacity(load) | 5-20T |

Thickness of panel | 82mm, 102mm or as requested |

Temperature | -18°C to 25°C |

Side door | optional |

Surface | Fibreglass reinforced plastic (FRP) |

Intermediate layer | PU(polyurethane) insulated, density: 42-45kg/m3 |

Edge Protector | Aluminium alloy |

Door seal | EPDM rubber |

Door frame & Locks | 304 stainless steel |

Strength:

1) Light in weight: 40% lighter than metal body.And durable

2) Better insulation: K value less than 0.3w/m2k..

3) High in strength and long life: 5 times longer than metal body.

4) Environmental protection::Non-corrosion, non-pollution, anti-brine, acid and soda-resisting, flat, smooth.

5) Install: Easy to be assembled and repaired at site

6)Temperature range: -24°C--+18°C,special request reach to -40°C

7) Customize :We could design special drawing according cilent's request , producing as client's requirement.

8) guarantee period :2 year

9) Certificate : CCC;ISO9001

Trade details:

1)Trade terms: CIF ,FOB,CFR,L/C

2)Payment: 30% prepaid in T/T ,70% payment in T/T before shippment.

3)MOQ: 1 Set.

4)Delivery time: 10 days around.

5)Transportation: Nornally transport by sea

6)Port of loading:Qingdao

7)MOQ:1 Unit

- Q: What is the difference between the board and the core board? The The

- 024 (thermal conductivity of the lower insulation effect The better) Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation The cost is still lower than the infusion process

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Color steel room life in general how many years

- The price with the upper and lower color plate thickness, polystyrene bulk density, there are regional differences are related. Specifically you can call the local color steel factory.

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Some areas have implemented energy-saving 50% standard, and some areas have already begun to implement 65% of the standard. Insulation material thickness is determined by the design institute according to the specific building shape factor, window wall ratio, wall thickness and other factors.

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask questions.

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- Can do the insulation that is the foam board, the so-called insulation of the extruded board with high Ji floating reed kill the devil ghost Tong Kankan Kun resistance, low linearity, low expansion characteristics of the structure of the closed-cell rate reached 99% Above, the formation of vacuum layer, to avoid air flow cooling, to ensure its long-term stability and stability, relative to the foam polyurethane 80% of the closed-hole rate, the leading advantage is self-evident

Send your message to us

Composite Sandwich Panels Insulated Fiberglass for Truck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords