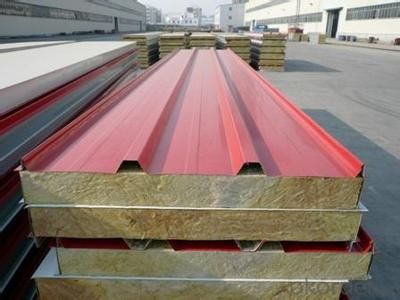

Sandwich Panels Composites GI GL CR Corrugated Steel Sheet Color Steel Laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy),with pallet |

| Delivery Detail: | 20-25 days after receiving the deposit |

Specifications

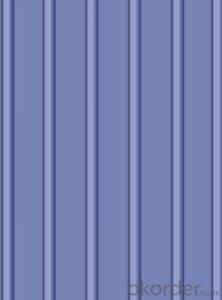

PPGI, PPGL , GI , GL, CR and Corrugated steel sheet

thickness : 0.12mm to 1.2mm,

width :600mm to 1500mm

zinc coat:30-275g

We can offer PPGI and GI in thickness available from 0.12mm to 1.2mm, width available from 600mm to 1500mm

Basic information

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 30-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

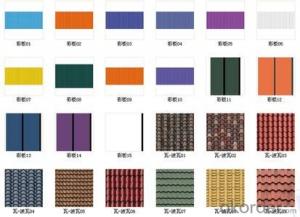

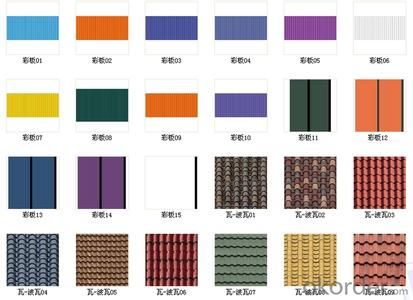

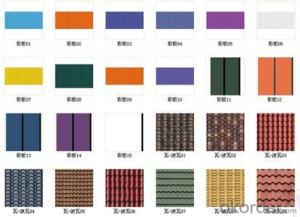

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

Brief Introductionof product

1. Color Coated steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color Coated Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color Coated Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color Coated Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

SGLCC | 140-350 | 270-500 | 22 |

SGLCD | 140-300 | 270-420 | 26 |

SGLCDD | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q: Color steel room life in general how many years

- Safety information complete directory directory Chapter 1 construction site safety technical data management of the main content and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technology The establishment of the data Section IV of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (second file Box) Section III of the target management (the third file box) Section IV of the safe construction of the organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (The sixth file box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident ( The eleventh section of the security box (the eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (tenth File box) Section XII mechanical equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union Labor protection information

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

- Q: Can the foam sandwich be used as a cleaning plate?

- In addition to the thickness, bending, corrosion does not meet the standard can not be used, there is no relevant specific provisions, buckle raft Gong Gong folder slander attack Wei Wei Shan pieces of steel pipe scaffolding is the advantage of re-use, easy disassembly, this problem a bit strange

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Flexible tube: flexible composite high-pressure transmission pipe products with patented technology installation and maintenance equipment, so that installation and maintenance more convenient, solid and reliable, to a greater extent reduce the cost of the project; no fire operations, greatly improving the oil field construction safety factor , Reducing the probability of personnel injury, and no need to rely on power supply, effectively shorten the installation and maintenance cycle, can quickly resume production; maintenance does not require cleaning lines Difference: composite pipe has good mechanical properties, with rust and oxidation resistance, acid and alkali, good resistance to intergranular corrosion and other chemical properties Flexible tube with good anti-tensile and anti-static, flame retardant performance; anti-fouling performance; flexible, light weight, transport fluid resistance is small, the use of free bending, long service life

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

- Q: The stove is dedicated to the plastic used for plastic paper

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

Send your message to us

Sandwich Panels Composites GI GL CR Corrugated Steel Sheet Color Steel Laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords